The rough floor is the prepared base for the finish coat: laminate, linoleum, parquet. The rough floor is wooden and concrete.  Layout of the rough floor on the logs. Advantages of the wooden floor:

Layout of the rough floor on the logs. Advantages of the wooden floor:

- ecological compatibility;

- heat insulation;

- good air permeability.

The disadvantage of the rough wooden floor can be considered that this design does not resist high humidity. Therefore, in the baths and steam rooms you can not install wooden logs.  Varieties of the black sex, depending on the type of base. Concrete screed also has its advantages:

Varieties of the black sex, depending on the type of base. Concrete screed also has its advantages:

- durability;

- soundproofing;

- high strength;

- resistance to moisture, burning and chemical attack;

- quick installation and affordable price.

The disadvantage of the screed is its coldsurface. Such a floor must necessarily be insulated. Regardless of the choice of floor, the technology for performing both designs is time-consuming and requires careful work.

Floor by hand made of wood material

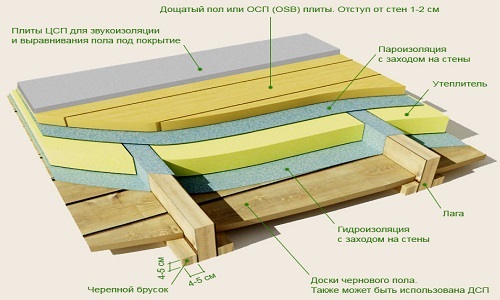

The construction of the wooden floor on the ground. Execution of a wooden floor has its own technology:

The construction of the wooden floor on the ground. Execution of a wooden floor has its own technology:

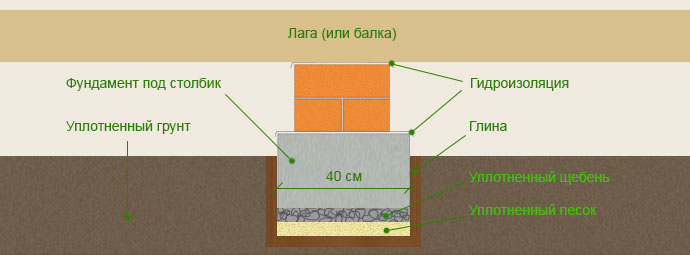

As the roughing timber bars, you canuse wood of the second or third grade. Those sides of the beams on which the floor covering will be laid should be leveled. Further, the wood must be treated with an antiseptic solution. This is done to ensure that the tree does not have insects that destroy the integrity of the material. You can install lags in two ways: by overlapping or by base. According to the first method, it is necessary to lay the lags of the lower strapping and to make grooves in them in those places where the lugs of the upper strap will be deposited. The depth of the grooves is equal to the width of the upper beams. The harness must be securely installed. To do this, perform brick posts, which will serve as support lags.  Scheme of leveling the roughing floor with plywood. The installation of the posts is carried out at the initial stage of the rough floor. This construction is also called the "columnar foundation." The technology is as follows:

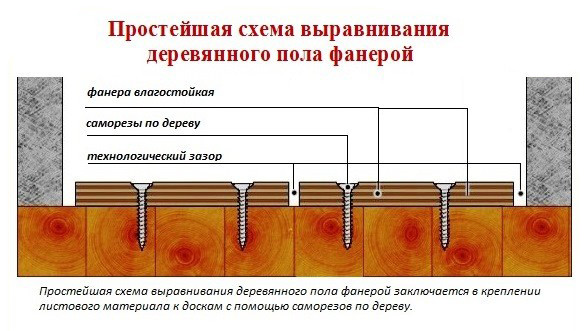

Scheme of leveling the roughing floor with plywood. The installation of the posts is carried out at the initial stage of the rough floor. This construction is also called the "columnar foundation." The technology is as follows:

The distance between the lags depends on the thicknesswood material: the thinner the bar, the closer the lag is. The laid beams must be fastened together. The device of the log "on the base" assumes removal of the top layer of soil and filling of the surface with small crushed stone. The base is laid with overlapping lag, as in the previous version. Further, the lower deck is provided. For this purpose, the supports are installed - the bars with a section of 50x40 mm and are fixed to the lower part of the lag. On the bottom base lay a waterproofing film, and on top a layer of a heater. At this stage, you need to decide on the finish. If it is a sheet material of chipboard, before its packing it is recommended to perform a crate of transverse bars, which are fixed on supports. Sheets of floor covering are laid on the lath so that their joints are located at the center of the lintels. Back to contents</a>

Rough floor of concrete structure

When pouring the rough floor flaws and irregularities are allowed. The purpose of the rough screed is to level the large differences in the surface along the height and create a foundation for a clean screed.  Scheme of the device of concrete floor. The step-by-step instruction looks like this:

Scheme of the device of concrete floor. The step-by-step instruction looks like this:

First you need to clean the surface of the garbageand using the level to determine the height of the screed. As beacons serve a pile of cement mixture of the desired height, which are laid metal profile. The guides are fixed with a solution. The height of the profiles is the level of the future screed. For a good grip of the rough screed with the base it must be prepared. To begin with, all the large depressions and cracks must be filled with mortar. Further, the surface is primed to improve the adhesion of the concrete to the surface of the substrate. All wires will be sealed in the screed. But before pouring all communications must be wrapped with insulating material and fixed to the base with dowels. On the perimeter of the room it is necessary to glue the damper tape, which compensates for the deformation of the screed. To prepare the solution, cement and sand are taken in the proportion of 1: 3. Water is added to the mixture gradually, until a creamy consistency is obtained. Approximately, the water flow is 0.5 kg per 1 kg of cement-sand mixture. The necessary tools for the preparation of mortar and pouring screed:

- shovel shovel;

- solution tank or electric concrete mixer;

- buckets;

- overalls.

The solution is filled between beacons andrule-rule distribute it. If voids are formed, then the mixture is reported to those places and equalized again. The cement mixture should be prepared in small portions, as the solution quickly solidifies. It is recommended to fill the floor with a single day, so that the surface is uniform. When drying, the screed can shrink. To prevent this, it is necessary to carry out such measures:

A good rough floor is the guarantee of a solid construction of the whole room. Quality installation and strict compliance with technology will serve as a basis for many decades. </ ul>