By equipping your house with interior elements, allthink about sleeping places. In the first place, thoughts of a bed and a sofa always come to mind. And then there is the problem of value, because both, and other design elements are quite expensive. You can offer an alternative option to save: make a sofa made of wood with your own hands. This is quite convenient, as in this case it is possible to get new skills in the construction craft, the main thing is to create an exclusive product.  Making a wooden sofa is not as difficult asit seems that you just need to carefully and consistently follow the manufacturing instructions. While doing, one should not be afraid of difficult technological moments. Everything is simple enough. The main thing is to carefully study the instructions for creating and do not rush, otherwise you can spoil something.

Making a wooden sofa is not as difficult asit seems that you just need to carefully and consistently follow the manufacturing instructions. While doing, one should not be afraid of difficult technological moments. Everything is simple enough. The main thing is to carefully study the instructions for creating and do not rush, otherwise you can spoil something.

How to make a frame on a corner sofa

Corner sofa - one of the most populardetails of the interior, as it is able to give a seat for a sufficiently large number of guests, and can also become an additional bed. You should be prepared for the fact that the creation of the sofa will take a long time. In order not to waste time in vain, you need to stock up the following materials and tools:

- edged boards;

- hacksaw for wood;

- screwdriver;

- measuring tape measure;

- self-tapping screws;

- aluminum corners.

Back to contents</a>

Stages of work execution

The scheme of the kitchen corner sofa assembly.

The scheme of the kitchen corner sofa assembly.

It is very important to purchase a bar for a high sofaquality, so that it is well dried. Otherwise, such a sofa will break very quickly into components, well, if at that moment no one will sit on it. Back to contents</a>

How to decorate the frame of a sofa

Diagram of sofa casing. To give the sofa a finished shape, the finished frame must be sewn, and this can be done with the help of the following tools:

Diagram of sofa casing. To give the sofa a finished shape, the finished frame must be sewn, and this can be done with the help of the following tools:

- hack-saws for wood;

- plywood with different thickness;

- jigsaw;

- grinding machine or sandpaper;

- varnish;

- roller wheels.

This process follows a certain technologywithout any derogation. Any sofa has legs, so initially they should be equipped with a skeleton. For this purpose, plywood is 1 cm thick and the foot area should be 5x5 cm on average. The main purpose of the supports is that the frame does not deteriorate and also that it does not damage the floor covering. Since this corner sofa will consist of two main sliding parts - angular and straight, it is good if the supports will have wheels. It's much easier to collect a sofa. Next, the jigsaw eliminates all the sticking corners of the boards, adjusts the armrests, if they are too wide, and other surpluses of the frame. At this stage, using sandpaper or a grinder, the entire surface of the wood is ground. The sanding process can take a long time. But if you neglect such a finish, the burrs from the boards will constantly ruin the upholstery fabric or when sitting on the product you will feel splinters.  Tools for making a sofa. It is necessary to open the wooden frame with varnish. When the autopsy works are carried out, it is desirable that there are no small children present in the house. On average, it takes 34-36 hours to dry the coating, after which you can continue working. A flexible sheet of plywood is fastened to the back of the sofa. This procedure will ensure the correct and reliable installation of the cushion and backrest to avoid their indentation. There is no need to use the EAF for this purpose, because it is expensive, and to perform the above function, you can use the material that is cheaper. Back to contents</a>

Tools for making a sofa. It is necessary to open the wooden frame with varnish. When the autopsy works are carried out, it is desirable that there are no small children present in the house. On average, it takes 34-36 hours to dry the coating, after which you can continue working. A flexible sheet of plywood is fastened to the back of the sofa. This procedure will ensure the correct and reliable installation of the cushion and backrest to avoid their indentation. There is no need to use the EAF for this purpose, because it is expensive, and to perform the above function, you can use the material that is cheaper. Back to contents</a>

The end of the sofa assembly for the house

Before you start the sofa to operate the house, it needs to be sewed and sewed. Tools for work:

- a construction stapler with staples;

- filler in the form of batting;

- fabric for upholstery;

- mattress and pillows;

- stationery knife;

- stationery glue.

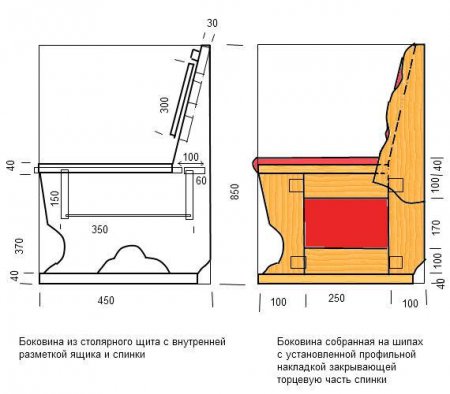

With the help of pillows and a mattress, the sofa is given a three-dimensional shape. After they are installed, you can start the upholstery of the sofa with a cloth.  Diagram of the sidewall of the sofa.

Diagram of the sidewall of the sofa.

After all the steps are completed, the sofa can beuse in the house. That such an element does not look mediocre, you can use different combinations of tissues. For example, light colors will soften the interior, but they are more marquee. But the screaming colors immediately attract the attention of guests, the sofa will be the highlight of the room. To leave the last doubts, whether it is worthwhile undertaking the very same work, there are several arguments:

Modern upholstery services are sufficientare high, therefore, doing self-manufacturing, you can not only save and realize your creative ideas, but also just have fun. </ ul>