Frameless chairs are used quite often,as they help to save the space of the apartment. If a pear chair is made by one's own hands, it can have any form popular with the owner. Often there is a form of puff, pear or bag. Sewing them is not too difficult, and a person who has basic skills in tailoring, will cope with such a task. For tailoring you will need:  The pear chair is very convenient to use, since it takes the form of the body of the person sitting on it.

The pear chair is very convenient to use, since it takes the form of the body of the person sitting on it.

- fabric for the inner case;

- fabric for outer cover;

- filler;

- one-piece zipper;

- scissors;

- pins;

- sewing machine;

- pencil or chalk;

- tape measure;

- Ruler;

- thread in tone.

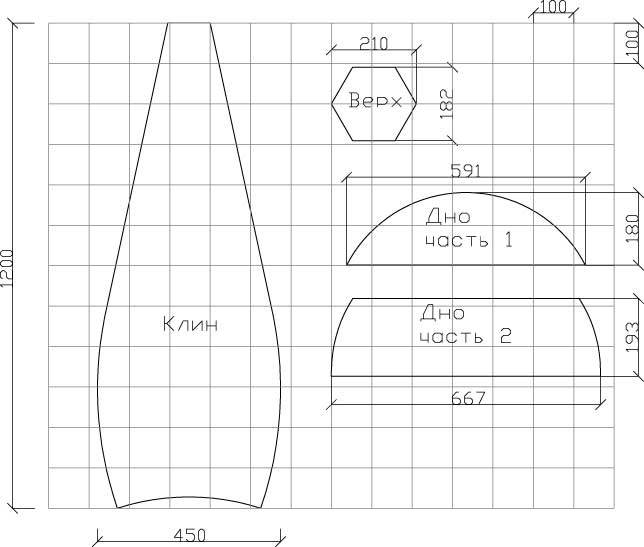

The pattern of such chairs can have minordifferences - they are in the form of a pear, soccer ball (the most complex variant, sewing from a set of hexagons) or rectangular. All other effects can be achieved with the help of color and texture, because the chairs in the nursery or the living room can have the same shape, but look completely different.

Armchair bag: choice of fabric

Pattern of a pear chair. Although such an armchair does not have a carcass and it's easy to make patterns for it, it is still furniture. Accordingly, the fabric of the top should be chosen pleasant and at the same time strong. The fabric for the inner cover can be any of those that have great strength for retaining the filler. Self-selection of the fabric will help to know the basic characteristics of tissues. Fine thin fabrics, such as coarse calico, satin or silk, will not fit, they will very quickly become worthless. The pear chair can be made from velor - this fabric is soft, fleecy and velvety, slightly reminiscent of artificial fur. Similar in its characteristics to the velor flock, which is cleaned and washed with ease and has water repellent properties. The armchair bag can be sewn from the shenil. It is a natural fabric with the addition of synthetics, strong, easy to clean. The surface of this type of tissue does not form spools. Synthetic fibers in the composition has jacquard - a fabric that looks like a boucle. This fabric is durable and easy to wash, and its loops do not dissolve from puffs. Artificial suede can be used, which does not burn out and does not require special care. Sturdy and beautiful for such products, artificial leather, which, unlike suede, can have on the surface of a different kind of embossing. And if there are no restrictions in the means, you can use tapestry fabrics. They are durable, antistatic and very beautiful. The width of such tissues usually ranges from 140-150 cm, which is very convenient for transferring patterns to them. Fabrics of a smaller width are better not to be considered, since a large footprint is required and difficulties with cutting can arise. In fabrics, the width of which is greater than the standard, there will be too much waste after cutting. Back to contents</a>

Pattern of a pear chair. Although such an armchair does not have a carcass and it's easy to make patterns for it, it is still furniture. Accordingly, the fabric of the top should be chosen pleasant and at the same time strong. The fabric for the inner cover can be any of those that have great strength for retaining the filler. Self-selection of the fabric will help to know the basic characteristics of tissues. Fine thin fabrics, such as coarse calico, satin or silk, will not fit, they will very quickly become worthless. The pear chair can be made from velor - this fabric is soft, fleecy and velvety, slightly reminiscent of artificial fur. Similar in its characteristics to the velor flock, which is cleaned and washed with ease and has water repellent properties. The armchair bag can be sewn from the shenil. It is a natural fabric with the addition of synthetics, strong, easy to clean. The surface of this type of tissue does not form spools. Synthetic fibers in the composition has jacquard - a fabric that looks like a boucle. This fabric is durable and easy to wash, and its loops do not dissolve from puffs. Artificial suede can be used, which does not burn out and does not require special care. Sturdy and beautiful for such products, artificial leather, which, unlike suede, can have on the surface of a different kind of embossing. And if there are no restrictions in the means, you can use tapestry fabrics. They are durable, antistatic and very beautiful. The width of such tissues usually ranges from 140-150 cm, which is very convenient for transferring patterns to them. Fabrics of a smaller width are better not to be considered, since a large footprint is required and difficulties with cutting can arise. In fabrics, the width of which is greater than the standard, there will be too much waste after cutting. Back to contents</a>

Pear chair: sewing process

The sheet is transferred to a millimeter paper toto ensure evenness. Uneven wedges spoil the appearance of the product, they must be exactly the same on both sides. The selected patterns are increased to the desired size, if desired, think over applications and other additional details. The upper and lower covers are transferred to the fabric, cut out taking into account the allowances for seams. In both the upper and lower part of the chair, the bag must consist of a top round part, smaller in size, and a lower, also round, but larger, and usually 6 wedges are made between them. All these details of the pattern must be sewn together, so that in the end the seat of the bag has turned out. First of all, all the wedges of the upper and lower covers are spent, but a small area remains unclean. The next stage is used for both bottoms. After these sewing operations are done with the upper and lower covers in turn, the chair bag can be adjusted to the appliqué if they are conceived. For the pear chair to be washed by hand, as it is used and contaminated, lightning is sewn into the remaining wedge of the upper cover that is not sewn. In order to keep the seat of the bag in a shape, a special filler made of expanded polystyrene is poured into the inner cover for 2/3 of the total volume. After that, the hole is sealed with a strong seam. Seams on the inner case must be double and are made with strong threads so that during use under the body weight the filler does not wake up from it. But it is also acceptable to sew a zipper in it, so that the inner cover can also be washed. It remains only to put on the seat bag an outer case and zip up - it is ready for operation.