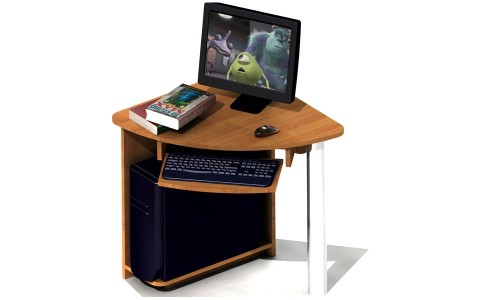

With the advent of personal computersit became actual to make a computer table with its own hands. Recently, computer desks have been gaining in popularity. Making a computer table with your own hands, you can not only get furniture with an individual design, but also significantly save your budget.  A homemade corner table will save space in the room and your budget. Of course, you can buy such a table in the store, but there are people who prefer to do everything themselves.

A homemade corner table will save space in the room and your budget. Of course, you can buy such a table in the store, but there are people who prefer to do everything themselves.

How to start making a table

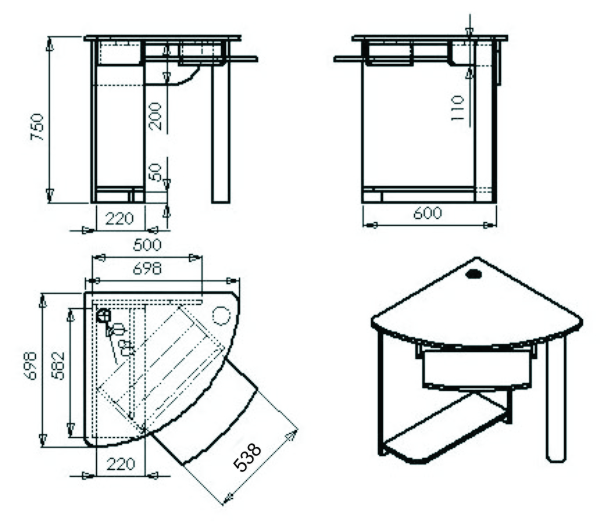

You can determine the size by looking at the diagramthe location of objects on the table. Before you make a corner computer desk, you need to determine the shape of the table, its dimensions, design and, possibly, with some additional functions. It is very important to clearly visualize its appearance, this will depend on the materials used in creating the table. Everything that can be needed in the process of work must be prepared in advance. Now it is necessary to compile the design of the computer table. When compiling it, it is necessary to take into account some parameters:

You can determine the size by looking at the diagramthe location of objects on the table. Before you make a corner computer desk, you need to determine the shape of the table, its dimensions, design and, possibly, with some additional functions. It is very important to clearly visualize its appearance, this will depend on the materials used in creating the table. Everything that can be needed in the process of work must be prepared in advance. Now it is necessary to compile the design of the computer table. When compiling it, it is necessary to take into account some parameters:

- functions of the table, it is important to provide for such trifles as the number of boxes, as well as the need for a shelf for the keyboard and other shelves for office equipment;

- height of the table, it is very important for whomThis table is made, if it is intended for an adult person, then a standard height is needed, if for a child, it is necessary to choose the correct height, focusing on the growth of the child, do not forget about the size of the pivoting chair;

- when planning additional shelves, you need to consider the size of office equipment and make shelves strictly for them;

- The size of the table should correspond to the room in which it will be, taking into account the furniture already located here.

Before starting work, you need to make a sketch of the table withall sizes. You can think over a place for storing CD-ROMs, for this you need to measure the width of the previously purchased plastic insert for disks. Now you need to execute a drawing in which all the necessary elements are marked with exact indication of all sizes. This is necessary in order to subsequently use the material most rationally. In the drawing, you must specify the number and type of fasteners. To make a computer table with your own hands, you will need the following tools:

Before starting work, you need to make a sketch of the table withall sizes. You can think over a place for storing CD-ROMs, for this you need to measure the width of the previously purchased plastic insert for disks. Now you need to execute a drawing in which all the necessary elements are marked with exact indication of all sizes. This is necessary in order to subsequently use the material most rationally. In the drawing, you must specify the number and type of fasteners. To make a computer table with your own hands, you will need the following tools:

- rulers;

- face plane;

- finished plastic insert for discs;

- a jigsaw;

- Screwdriver Set;

- Circular Saw;

- drill and set of drills.

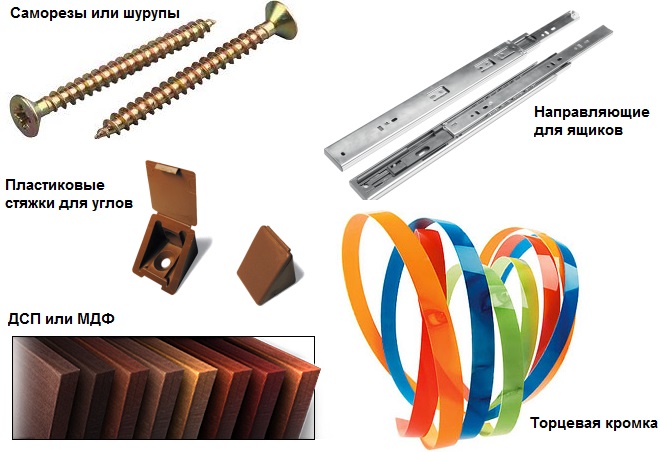

From the materials for the computer table, you will need:  List of materials for manufacturing a computer table.

List of materials for manufacturing a computer table.

- pine boards needed to strengthen the product, the optimal thickness will be a board of 25 mm;

- for shelves, drawers and side walls, it is better to take the MDF plate in the amount required by the drawing;

- screws for fastening, about 130 pcs .;

- guides for shelves and boxes, their number will depend on the number of these elements;

- plastic ties for corners;

- edge and grinding skins for processing the edges of drawers and shelves;

- varnish or primer for finishing.

It is not difficult to make a computer table with your own hands, but you need to be very careful when putting dimensions on drawings and when cutting individual elements from a large canvas. Back to contents</a>

Table assembly with drawers

After all the necessary elements are cut out,you can start assembling the computer table. Start the assembly with the side elements. At the same stage, we mount the guides under the drawer and under the drawers. You need to do this very accurately in order to avoid skewing of the boxes with further use. Then all the side walls are connected by means of dowels. In order to make the fastener more durable, it is possible to add PVA glue to the holes. Further, all the walls are fixed using self-tapping screws. Edges that are visible are processed with edge band, such tape is fastened with a conventional hot iron, it can be ironed through a thin cloth or ordinary paper.  Tools for making the table: a drill, a jigsaw, a screwdriver, screwdrivers, pliers. The computer table can be installed depending on the pre-selected design. You can buy special metal round legs with a plastic base to avoid scratches on the floor, or at the initial stage, when designing, provide the main emphasis on the side cabinets installed on the above metal legs or simply on additional slats made from a similar to the side racks of the material. After all the edges of the computer table are processed, you need to fix the countertop. As a rule, it is simply fixed on the dowels, pre-adding the PVA glue to the holes. Holes for them are prepared in advance, before turning the countertop, using a drill. It is best to use the limiter in this case, since the depth of drilling is small and it is possible, by carelessness, to damage the front side of the countertop. Now we install the board intended for the keyboard in the guides and insert the boxes. We check whether everything works. In the event that, according to your project, the monitor will not be mounted on the countertop, but on a separate shelf, it is best to mount it on a special metal stand, first, it's very stylish, and secondly, reliably. Back to contents</a>

Tools for making the table: a drill, a jigsaw, a screwdriver, screwdrivers, pliers. The computer table can be installed depending on the pre-selected design. You can buy special metal round legs with a plastic base to avoid scratches on the floor, or at the initial stage, when designing, provide the main emphasis on the side cabinets installed on the above metal legs or simply on additional slats made from a similar to the side racks of the material. After all the edges of the computer table are processed, you need to fix the countertop. As a rule, it is simply fixed on the dowels, pre-adding the PVA glue to the holes. Holes for them are prepared in advance, before turning the countertop, using a drill. It is best to use the limiter in this case, since the depth of drilling is small and it is possible, by carelessness, to damage the front side of the countertop. Now we install the board intended for the keyboard in the guides and insert the boxes. We check whether everything works. In the event that, according to your project, the monitor will not be mounted on the countertop, but on a separate shelf, it is best to mount it on a special metal stand, first, it's very stylish, and secondly, reliably. Back to contents</a>

Place for the system unit

If you are going to use thiscomputer desk a personal computer, not a laptop, you need to provide a place for the system unit. The best stand for these purposes is a special stand. It is not difficult to manufacture, but there will be a lot of convenience from it. You do not have to clutter up your desk with unnecessary elements, while the systemist will be very mobile, there will not be a rigid binding of it to the table. You need a base cut to the size of the system unit, as well as two side slats. You can attach beautiful metal legs to the base with a plastic base or install wheels instead. Making a table with your own hands is not too complicated and very fascinating. But you need to approach it with responsibility. The main thing is to provide at the initial stage all the details, and also very accurately to cut out individual elements. And then the table made by own hands will surpass all your expectations. </ ul>