Repairing a fairly worn floor coveringor arranging a new one, it is worth considering the responsibility and importance of holding such events. Such a flooring should harmoniously fit into the overall interior of the room, adding notes of perfection and sophistication.  Scheme of dry floor screed. Traditionally, before the base works, the floor surface must be leveled, for this purpose a screed is made. This coating can be wet or dry. The wet method of leveling the surface is most often used, however, such measures take a lot of time and it is rather difficult to conduct them. In addition, this kind of work is dusty and dirty. A dry floor screed allows for installation using a simplified scheme.

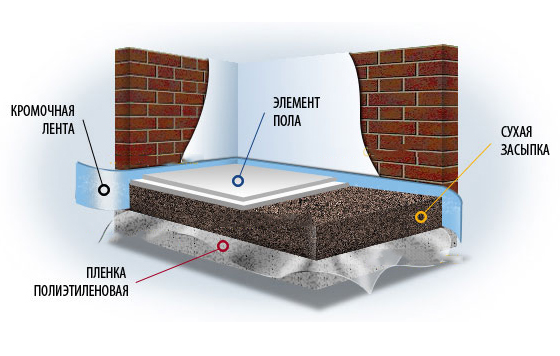

Scheme of dry floor screed. Traditionally, before the base works, the floor surface must be leveled, for this purpose a screed is made. This coating can be wet or dry. The wet method of leveling the surface is most often used, however, such measures take a lot of time and it is rather difficult to conduct them. In addition, this kind of work is dusty and dirty. A dry floor screed allows for installation using a simplified scheme.

The main points of using the dry floor leveling method

Important parameters of such coverage:  Tools for floor screed.

Tools for floor screed.

What you need to work:

- metal profiles;

- polyethylene film;

- Edge band;

- expanded clay;

- gypsum-fiber sheets with a moisture-resistant base;

- self-tapping screws;

- glue.

Attention! The method of such leveling of the base is carried out by blocks with observance of the basic stages of carrying out of work. Back to contents</a>

Surface preparation

Dry screed under the floor covering. Dry floor screed with their own hands is carried out at the time when all the work of the plumbing, electrical engineering plan is carried out. The beginning of such activities should be connected with the control of heating, sewerage, water supply system. The old coating must necessarily be removed, the subsequent work is associated with the leveling of the surface. The existing chips, pits and crevices are cemented with cement mortar. The protruding elements are removed by the Bulgarian, then processed. Upon completion of work, the garbage is removed using an industrial vacuum cleaner. The walls are marked with the level of the finished screed. On the finished floor, polyethylene or parchment is placed with an overlap of 15-25 cm. When reaching the walls, the film should be raised to the level previously indicated. Such a height is most often equated to 6 cm. The variety of the material used is determined by the features of the surface. Concrete coatings require laying out polyethylene, the thickness of which is 200-250 microns. The wood is covered with paper impregnated with bitumen or pergamon.

Dry screed under the floor covering. Dry floor screed with their own hands is carried out at the time when all the work of the plumbing, electrical engineering plan is carried out. The beginning of such activities should be connected with the control of heating, sewerage, water supply system. The old coating must necessarily be removed, the subsequent work is associated with the leveling of the surface. The existing chips, pits and crevices are cemented with cement mortar. The protruding elements are removed by the Bulgarian, then processed. Upon completion of work, the garbage is removed using an industrial vacuum cleaner. The walls are marked with the level of the finished screed. On the finished floor, polyethylene or parchment is placed with an overlap of 15-25 cm. When reaching the walls, the film should be raised to the level previously indicated. Such a height is most often equated to 6 cm. The variety of the material used is determined by the features of the surface. Concrete coatings require laying out polyethylene, the thickness of which is 200-250 microns. The wood is covered with paper impregnated with bitumen or pergamon.  Leveling of loose material under a dry screed. Installation of a vapor barrier layer is a prerequisite. The lack of such protection will lead to the gradual destruction of sex. Taking into account the fact that extraneous sounds penetrate into the room along dense parts, the space between the partition and the surface of the dry screed is left free. This gap has a width of 8-10 mm. Throughout the whole area of the room, a sound-absorbing tape is applied on the basis of mineral wool, fiberglass, polyethylene foam. So, sounds will not enter the room, and the surface of the floor as a result of periodic expansions from heating will be perfectly smooth. It is known that dry screed is a loose substance, which can not be leveled without special devices. In such a mass of legs quickly get bogged down, and the integrity of the coating is immediately broken. To make the coupler perfectly flat, the beacons are used. As an analog of such elements, U-shaped guides are often used, they are placed with a point upward and fixed on the bottom. Between them, later they fall asleep with expanded clay. Back to contents</a>

Leveling of loose material under a dry screed. Installation of a vapor barrier layer is a prerequisite. The lack of such protection will lead to the gradual destruction of sex. Taking into account the fact that extraneous sounds penetrate into the room along dense parts, the space between the partition and the surface of the dry screed is left free. This gap has a width of 8-10 mm. Throughout the whole area of the room, a sound-absorbing tape is applied on the basis of mineral wool, fiberglass, polyethylene foam. So, sounds will not enter the room, and the surface of the floor as a result of periodic expansions from heating will be perfectly smooth. It is known that dry screed is a loose substance, which can not be leveled without special devices. In such a mass of legs quickly get bogged down, and the integrity of the coating is immediately broken. To make the coupler perfectly flat, the beacons are used. As an analog of such elements, U-shaped guides are often used, they are placed with a point upward and fixed on the bottom. Between them, later they fall asleep with expanded clay. Back to contents</a>

The process of leveling the floor with a dry mix

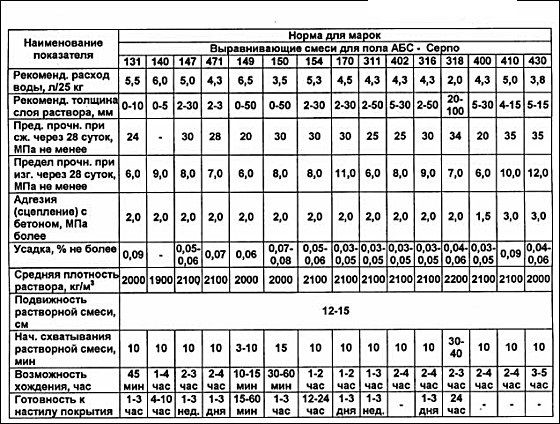

Technical data of leveling compoundsfor floors. The process of dry alignment is associated with the uniformity of the composition itself. Here you can use claydite, quartz sand, slag fine granularity, perlite. This raw material keeps the heat well, does not give outsiders the chance to enter the room, practically does not sag and has a light weight. Such characteristics are characterized by many dry mixtures. Accordingly, a large number of existing unevennesses require the backfilling of a significant amount of dry matter. In addition, in the backfilling layer you need to lay the necessary communications. Usually the height of such an interlayer corresponds to 3-4 cm, more than 6 cm do it impractical. Large heights require the reinforcement of the screed with sheet material. The amount of dry matter is determined by the progress of work: do not take a lot, just gradually, spreading the sheets, pour a small amount of substance. Otherwise, the process of moving around the room will be difficult with tying the legs in dry material. In addition, small elements of such material will be on the sticky zone, interfering with the fixing process. Back to contents</a>

Technical data of leveling compoundsfor floors. The process of dry alignment is associated with the uniformity of the composition itself. Here you can use claydite, quartz sand, slag fine granularity, perlite. This raw material keeps the heat well, does not give outsiders the chance to enter the room, practically does not sag and has a light weight. Such characteristics are characterized by many dry mixtures. Accordingly, a large number of existing unevennesses require the backfilling of a significant amount of dry matter. In addition, in the backfilling layer you need to lay the necessary communications. Usually the height of such an interlayer corresponds to 3-4 cm, more than 6 cm do it impractical. Large heights require the reinforcement of the screed with sheet material. The amount of dry matter is determined by the progress of work: do not take a lot, just gradually, spreading the sheets, pour a small amount of substance. Otherwise, the process of moving around the room will be difficult with tying the legs in dry material. In addition, small elements of such material will be on the sticky zone, interfering with the fixing process. Back to contents</a>

Layout: Recommendations

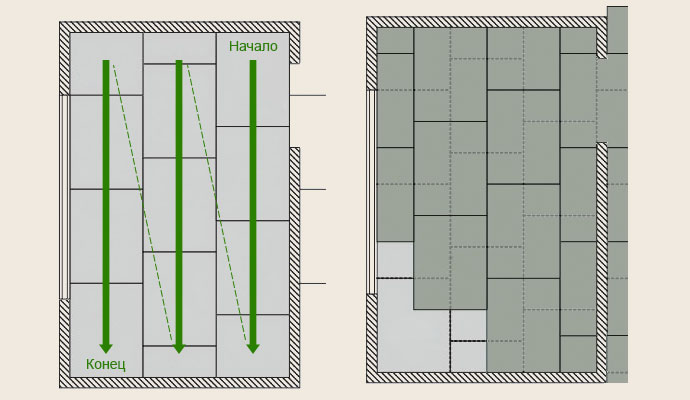

Scheme laying sheets of dry floor screed. The sheets are laid out on a pre-leveled surface. These include decking from different manufacturers, wood chip boards, sheet and gypsum-fiber coatings, plywood with a moisture-resistant base, asbestos-cement slabs. Such materials are laid out in turn, being fixed with each other. It is most difficult to work with the first sheet, other coatings will be fixed relative to it. Too deepen and move it over the surface is not recommended. All materials are laid on a dry surface so that the beginning of work coincides with the location in the door space. In this way, the smoothness of the surface can be maintained. Sheets laid on heat-insulating slabs require flooring from a wall located on the opposite side of the doorway. Taking into account such indicators of the material, as thickness and variety of composition, the slabs are laid in 1 or 2 layers. From the gypsum-fiber materials, the fold is pre-cut. This creates a double layer of similar sheets throughout the room. The laying of this material is associated with a mandatory displacement resembling a brickwork. In this way, you can achieve a special strength and stability of the coating. Identify the place of such sheets alone is difficult because of the large mass of material. Prepared plates are fixed with screws. They are screwed in every 10-15 cm. The additional strength can be given to the coating with building glue. Unevenness and seams can be covered with putty and sanded. The upper part of such sheets is treated with bitumen. Now you can start laying any finish coat after the dry floor leveling has been carried out. Back to contents</a>

Scheme laying sheets of dry floor screed. The sheets are laid out on a pre-leveled surface. These include decking from different manufacturers, wood chip boards, sheet and gypsum-fiber coatings, plywood with a moisture-resistant base, asbestos-cement slabs. Such materials are laid out in turn, being fixed with each other. It is most difficult to work with the first sheet, other coatings will be fixed relative to it. Too deepen and move it over the surface is not recommended. All materials are laid on a dry surface so that the beginning of work coincides with the location in the door space. In this way, the smoothness of the surface can be maintained. Sheets laid on heat-insulating slabs require flooring from a wall located on the opposite side of the doorway. Taking into account such indicators of the material, as thickness and variety of composition, the slabs are laid in 1 or 2 layers. From the gypsum-fiber materials, the fold is pre-cut. This creates a double layer of similar sheets throughout the room. The laying of this material is associated with a mandatory displacement resembling a brickwork. In this way, you can achieve a special strength and stability of the coating. Identify the place of such sheets alone is difficult because of the large mass of material. Prepared plates are fixed with screws. They are screwed in every 10-15 cm. The additional strength can be given to the coating with building glue. Unevenness and seams can be covered with putty and sanded. The upper part of such sheets is treated with bitumen. Now you can start laying any finish coat after the dry floor leveling has been carried out. Back to contents</a>

How long does the process last?

Types of fixing the plates of a dry floor covering. Basically, the process of making a dry screed goes much faster, when compared with the preparation of a concrete base. The mixture is poured and leveled in a short period of time. The time spent for this time can not be compared with the mixing of concrete, even if they have the same volume. In addition, the very process of tightening screws and spreading on the base of the adhesive lead to losses of several hours. Yes, and the process of laying sheets requires special care and a small speed of carrying out such work. The process of building a dry screed is quite simple and primitive. Here you do not need to buy special devices and wait for the advent of favorable weather. Works are carried out in any season in the shortest possible time. Dry coating does not harden ahead of time, and the quality of the work will be at an altitude. Even a beginner can cope with such work. The laid dry floor screed with your own hands allows you to carry out further finishing activities immediately. Such a coating has the same sound-insulating and excellent heat-retaining parameters. </ ul>

Types of fixing the plates of a dry floor covering. Basically, the process of making a dry screed goes much faster, when compared with the preparation of a concrete base. The mixture is poured and leveled in a short period of time. The time spent for this time can not be compared with the mixing of concrete, even if they have the same volume. In addition, the very process of tightening screws and spreading on the base of the adhesive lead to losses of several hours. Yes, and the process of laying sheets requires special care and a small speed of carrying out such work. The process of building a dry screed is quite simple and primitive. Here you do not need to buy special devices and wait for the advent of favorable weather. Works are carried out in any season in the shortest possible time. Dry coating does not harden ahead of time, and the quality of the work will be at an altitude. Even a beginner can cope with such work. The laid dry floor screed with your own hands allows you to carry out further finishing activities immediately. Such a coating has the same sound-insulating and excellent heat-retaining parameters. </ ul>