OSB plate - composite material of modernproduction. Almost immediately after his appearance, he won leading positions in the construction industry. Such popularity is associated with its high strength, while it does not depend on the direction of the applied force. This material absorbed all the advantages of natural wood, while it does not have its drawbacks.  Layout of OSB floors.OSB boards are very often used during renovation work, namely as a subfloor. everyone can do it with their own hands, the main thing is to follow certain recommendations and technology. Oriented strand board is a great option for making subfloors. It should be noted that it can be used in any room. Ease of installation allows you to carry out the work as quickly as possible. When finished, the floor surface is perfectly flat. Any kind of floor covering can subsequently be laid on such a base.

Layout of OSB floors.OSB boards are very often used during renovation work, namely as a subfloor. everyone can do it with their own hands, the main thing is to follow certain recommendations and technology. Oriented strand board is a great option for making subfloors. It should be noted that it can be used in any room. Ease of installation allows you to carry out the work as quickly as possible. When finished, the floor surface is perfectly flat. Any kind of floor covering can subsequently be laid on such a base.

Laying slabs on a concrete screed

Laying the OSB slab on a concrete base, you cansimultaneously solve several different tasks. There are features. First, the sheet material is able to hide minor unevenness of the concrete floor, creating a flat surface. Secondly, the sound- and noise-permeability of the overlap decreases and the insulation of the room increases significantly.  Installation of OSB boards on a concrete base.It is necessary to install wooden logs on the base if there are significant irregularities on it that need to be eliminated. If there are no such defects, OSB boards are laid directly on the floor. If the boards will be laid on logs, it is necessary to use a material with a thickness of at least 8 mm, while it is recommended to make two layers. This will make the floor strong enough so that it won't sag when walking. Ring nails must be used to secure the slabs to the beams. It is very important to control that the joints of the slabs fall exactly in the middle of the bar. If the OSB is laid directly on the concrete screed, you can make one layer, you can use an adhesive to fix it or fix it with dowels. Important! When laying OSB sheets, a small gap of 3 mm must be left between them. This is necessary so that the sheets can expand freely during acclimatization. Thus, the gap will not allow the sheets to deform. It is necessary to retreat from the walls a distance of 10 to 15 mm. In order to, between the beams, it is recommended to pre-lay a heat-insulating and vapor barrier material. It is very important that it is tightly pressed against the wooden blocks. If gaps remain, they can form cold bridges. When starting to lay the slabs, it is recommended to impregnate the lower part with bitumen mastic. It is necessary to fasten the OSB with self-tapping screws, while it is also important to take into account the expansion gaps. The second layer must be laid perpendicular to the first. To keep the material stationary, a layer of glue can be applied between the layers. Back to the table of contents</a>

Installation of OSB boards on a concrete base.It is necessary to install wooden logs on the base if there are significant irregularities on it that need to be eliminated. If there are no such defects, OSB boards are laid directly on the floor. If the boards will be laid on logs, it is necessary to use a material with a thickness of at least 8 mm, while it is recommended to make two layers. This will make the floor strong enough so that it won't sag when walking. Ring nails must be used to secure the slabs to the beams. It is very important to control that the joints of the slabs fall exactly in the middle of the bar. If the OSB is laid directly on the concrete screed, you can make one layer, you can use an adhesive to fix it or fix it with dowels. Important! When laying OSB sheets, a small gap of 3 mm must be left between them. This is necessary so that the sheets can expand freely during acclimatization. Thus, the gap will not allow the sheets to deform. It is necessary to retreat from the walls a distance of 10 to 15 mm. In order to, between the beams, it is recommended to pre-lay a heat-insulating and vapor barrier material. It is very important that it is tightly pressed against the wooden blocks. If gaps remain, they can form cold bridges. When starting to lay the slabs, it is recommended to impregnate the lower part with bitumen mastic. It is necessary to fasten the OSB with self-tapping screws, while it is also important to take into account the expansion gaps. The second layer must be laid perpendicular to the first. To keep the material stationary, a layer of glue can be applied between the layers. Back to the table of contents</a>

Laying OSB slabs on parquet and laminate

Installation of OSB plates on a wooden floor. Parquet should be laid on a flat and strong rough floor, such will be the basis of OSB slabs. OSB slabs exceed the technical quality of conventional plywood and can only compare with plywood PSF, but at a price they are much cheaper. There are some recommendations for installation work on laying parquet:

Installation of OSB plates on a wooden floor. Parquet should be laid on a flat and strong rough floor, such will be the basis of OSB slabs. OSB slabs exceed the technical quality of conventional plywood and can only compare with plywood PSF, but at a price they are much cheaper. There are some recommendations for installation work on laying parquet:

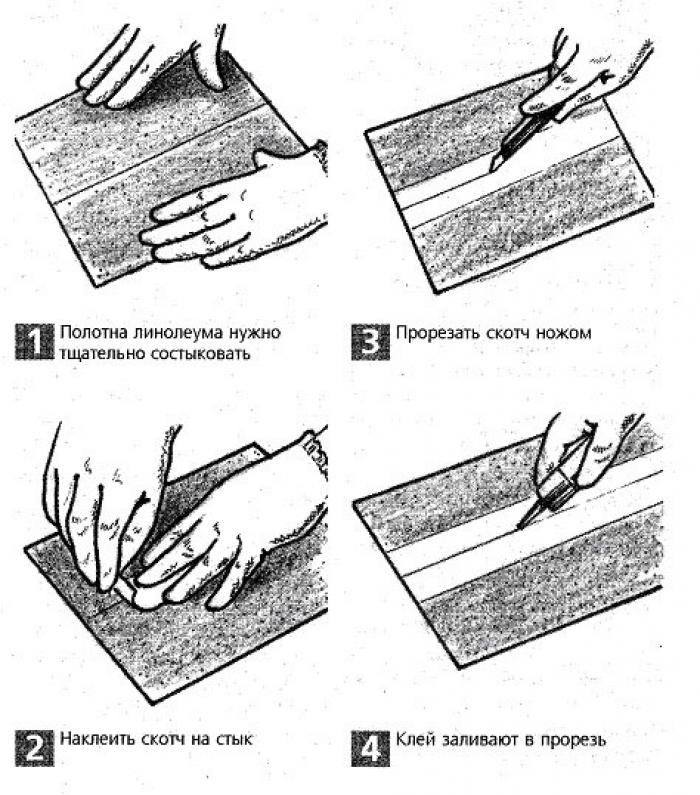

Roll coating is more sensitive to changesheights and various defects of the base. Therefore, for laying linoleum, the surface must be ground, and all gaps are treated qualitatively with a sealant. Also, the self-tapping screws should not protrude above the plate surface, as they can damage the roll coating. For gluing a roll flooring, special glue can be used if the room has a large enough area and double-sided adhesive tape if the room is small. With the help of OSB slabs it is possible to level the floors very quickly and qualitatively, to prepare a base for laying decorative floor covering. In order to do all the work yourself, it is worthwhile to prepare a minimal set of tools that almost every man has.

- a hacksaw on wood;

- grinding machine and sandpaper;

- self-tapping screws of suitable size;

- drill;

- screwdriver.

In order to achieve the desired result,It is necessary to apply the main recommendations that are given by specialists. Such a floor will serve its owner for a long time, without requiring at the same time to carry out frequent repairs.