Some home masters resort to a solutionmake the loggia insulated. If it is combined with the kitchen, additional space appears in the room, which can be used functionally by installing a bar rack in it. This element of the interior can be purchased to order, and you can make a stand with your own hands. This piece of furniture can be installed not only in the kitchen, but also in the hall, as well as the winter garden, if it is a private or country house.  The scheme of the bar. Some people, taking advantage of the experience of the inhabitants of America, try to replace the table with a sturdy table, but after they realize that the idea is a failure, because it runs counter to our traditions. After all, behind the counter you will not be able to fit the whole family with the children. Thus, a bar counter in the dining room or in the kitchen can be installed, but it is not worth to refuse from the main table.

The scheme of the bar. Some people, taking advantage of the experience of the inhabitants of America, try to replace the table with a sturdy table, but after they realize that the idea is a failure, because it runs counter to our traditions. After all, behind the counter you will not be able to fit the whole family with the children. Thus, a bar counter in the dining room or in the kitchen can be installed, but it is not worth to refuse from the main table.

Preparatory work

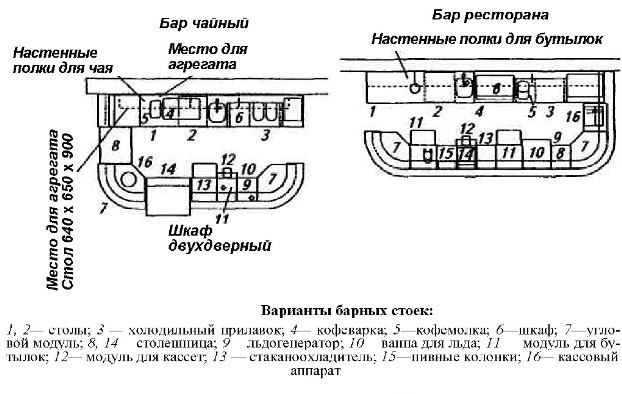

As the optimum construction heightchoose 110-115 cm. The bar counter should be made even more functional than usual, for this, shelves can be mounted at the bottom, and hooks for attaching glasses on top. It is recommended to equip the structure with some fashionable and necessary additions like a built-in key for uncorking bottles, roll-out shelves, a compartment where an ice bucket will be installed. If there is a great desire, but the kitchen space is very limited, then the tall structure will look out of place. In this case, it is recommended to design the system as a folding extension of the dining table. Particleboard and sewer pipes can be used as the main material.  Variants of bar counters. The store will purchase 6 sheets of chipboard with the following dimensions: 16x440x1150 mm, 2 more sheets should be 16x1000x2000 mm. For the work is useful and rake in dimensions 20h40h4000 mm. The support leg of the rack will be made of a standard new PVC pipe, the diameter of which is 180 mm, while the length of the element is 950 mm. The luminaire body will need to be made of the same material, however, the length of the element should be equivalent to 450 mm. Horizontally located leg support will be made of a metal pipe with a diameter of 50 mm and a length of 1 m. For fastening, you should use dowels with dimensions of 5x50 mm and in the amount of 80 pieces. Used screws should be equipped with a countersunk head, you need to purchase fasteners with the following dimensions: 4x60 mm, 4x80 mm. Back to contents</a>

Variants of bar counters. The store will purchase 6 sheets of chipboard with the following dimensions: 16x440x1150 mm, 2 more sheets should be 16x1000x2000 mm. For the work is useful and rake in dimensions 20h40h4000 mm. The support leg of the rack will be made of a standard new PVC pipe, the diameter of which is 180 mm, while the length of the element is 950 mm. The luminaire body will need to be made of the same material, however, the length of the element should be equivalent to 450 mm. Horizontally located leg support will be made of a metal pipe with a diameter of 50 mm and a length of 1 m. For fastening, you should use dowels with dimensions of 5x50 mm and in the amount of 80 pieces. Used screws should be equipped with a countersunk head, you need to purchase fasteners with the following dimensions: 4x60 mm, 4x80 mm. Back to contents</a>

Procurement of rack elements

Bar counter must undergo largeload, so it must be made strong. This involves the initial bonding with each other by glue of the particleboard, in the end you will be able to get sheets with a thickness of 32 mm. Two plates with dimensions 16x440x1150 mm should be left in their original form. At the next stage, you can proceed to cutting the chipboard, from which you want to prepare:  Accessories for the bar rack.

Accessories for the bar rack.

- circle Ø175 mm;

- floor element in the form of a circle Ø500 mm;

- podpyatochnuyu part of the support in the form of a circle Ø300 mm;

- ceiling hood in the form of a ring that has an outer diameter of 300 mm, an inner diameter of 180 mm;

- frame for the lower tube: two rings with an outer diameter of 240 mm and an inner diameter of 180 mm;

- The wall between the shelf and the table top is 870x240 mm.

In the element under the first position it is necessary to equipin the center of the hole, which is useful for wiring. The bar counter should have smooth shapes, for this, on one side, you need to round the plates with dimensions of 32x440x1150 mm. It follows from the rounded edge to retreat 190 mm, while from the side edges this retreat should be 130 mm. In the indicated place, it is necessary to equip a hole with a diameter of 180 mm, it is useful for installing a vertically placed support tube. Producing a bar rack with your own hands, in one of the 16 mm slabs you need to equip a similar cutout, which will be represented by a technological blind hole for mounting a vertical pipe. Then you can strengthen the workpiece with the second 16 mm element by glue and cut out the countertop. As soon as it is possible to make gluing, it is necessary to tighten the workpiece with clamps and wait for the complete setting of the composition, the cut must be made only after this. Back to contents</a>

Construction technology

Sawn preforms should be a bitprepare, which involves stripping the ends, then they must be plastered and sanded. Before installation, all round elements and plastic pipes must be covered with paint or varnished 2 times.  The scheme of the bar assembly. The assembly should begin with the fact that between the table top and the bottom of the recessed shelf, you need to install a vertical wall 240x870 mm, using the Ø5 mm dowels. This element must be located strictly in the middle of the table top. Further, using a pipe, the length of which is 450 mm, with an indentation from the edge of 20 mm, you need to do around the perimeter of 6 through holes Ø3 mm. It is a pipe designed for the lamp body. On the pipe, you need to wear a ring from the chipboard, whose width is 30 mm. Its fixing must be made by screws through the drilled holes, they must be removed 12 mm from the bottom edge of the element. On the opposite edge, you need to install a ceiling hood. On this body for the lamp can be considered ready, it is permissible to proceed to the support leg of the rack. At a distance of 200 mm from the lower end, it is necessary to drill a hole for the installation of a transverse metal tube, it will perform the function of a leg support. In the right place, the template should be fixed to the leg, in which quality a paper circle of Ø50 mm should be used. A large number of holes are to be arranged around the perimeter, using a 9 mm drill. This will allow you to dislodge the circle on the surface of the element, but you can make the edges aesthetic and smooth by applying a round file. Circle diameter of 175 mm should be attached to the ceiling, using dowels and screws. Through the hole you need to skip the wiring. The circle of the luminaire is fixed on the circle and fixed with screws. The ceiling hood, which is located on the body, should be moved slightly upward, it must also be screwed to the ceiling. To the ring of wood chipboard by means of dowels and glue composition it is necessary to strengthen the upper shelf. In the hole, mount the luminaire and fix it inside the case. The support bars must be fixed mechanically to the rectangular ends of the shelves. Reiki, reinforced to the wall, will hold the rack in the desired final position. Then comes the turn of the support leg, which should be strengthened in the thrust bearing, it needs to install a transverse metal pipe. The crossbar must be fixed to the wall with a coupling. Next, you can install a table top and shelves. If after you have finished making the rack, there are unpainted elements, this needs to be corrected by applying a paint or varnish, applying the composition in two layers. The following tools and materials are to be prepared for the work:

The scheme of the bar assembly. The assembly should begin with the fact that between the table top and the bottom of the recessed shelf, you need to install a vertical wall 240x870 mm, using the Ø5 mm dowels. This element must be located strictly in the middle of the table top. Further, using a pipe, the length of which is 450 mm, with an indentation from the edge of 20 mm, you need to do around the perimeter of 6 through holes Ø3 mm. It is a pipe designed for the lamp body. On the pipe, you need to wear a ring from the chipboard, whose width is 30 mm. Its fixing must be made by screws through the drilled holes, they must be removed 12 mm from the bottom edge of the element. On the opposite edge, you need to install a ceiling hood. On this body for the lamp can be considered ready, it is permissible to proceed to the support leg of the rack. At a distance of 200 mm from the lower end, it is necessary to drill a hole for the installation of a transverse metal tube, it will perform the function of a leg support. In the right place, the template should be fixed to the leg, in which quality a paper circle of Ø50 mm should be used. A large number of holes are to be arranged around the perimeter, using a 9 mm drill. This will allow you to dislodge the circle on the surface of the element, but you can make the edges aesthetic and smooth by applying a round file. Circle diameter of 175 mm should be attached to the ceiling, using dowels and screws. Through the hole you need to skip the wiring. The circle of the luminaire is fixed on the circle and fixed with screws. The ceiling hood, which is located on the body, should be moved slightly upward, it must also be screwed to the ceiling. To the ring of wood chipboard by means of dowels and glue composition it is necessary to strengthen the upper shelf. In the hole, mount the luminaire and fix it inside the case. The support bars must be fixed mechanically to the rectangular ends of the shelves. Reiki, reinforced to the wall, will hold the rack in the desired final position. Then comes the turn of the support leg, which should be strengthened in the thrust bearing, it needs to install a transverse metal pipe. The crossbar must be fixed to the wall with a coupling. Next, you can install a table top and shelves. If after you have finished making the rack, there are unpainted elements, this needs to be corrected by applying a paint or varnish, applying the composition in two layers. The following tools and materials are to be prepared for the work:  Tools for mounting the bar rack.

Tools for mounting the bar rack.

- chipboard;

- pipes;

- dowels;

- device for lighting;

- wires;

- colored varnish;

- putty;

- acrylic paint;

- Screws;

- hacksaw;

- electric jigsaw;

- Clamps;

- drill;

- drill;

- screwdriver;

- round file;

- a grinding bar;

- paint brush;

- putty knife.

The manufacturing process itself is not so complicated, but it is better to entrust the cutting of the material to professionals, since they use modern equipment.