Windows are the most important element of any home. At present, plastic windows are the most popular, but wooden windows do not lose their relevance. Installing windows with your own hands allows you to exclude dependence on construction from someone else.  Before installing plastic windows,carefully measure openings, because they often have a non-exact geometric shape. At first glance the whole process of installing window frames seems very complicated. In fact, if you understand the basic rules, then this operation will not seem impossible. Installation of windows with your own hands, and any type, is available and many are successfully used in the construction of the house.

Before installing plastic windows,carefully measure openings, because they often have a non-exact geometric shape. At first glance the whole process of installing window frames seems very complicated. In fact, if you understand the basic rules, then this operation will not seem impossible. Installation of windows with your own hands, and any type, is available and many are successfully used in the construction of the house.

Window constructions

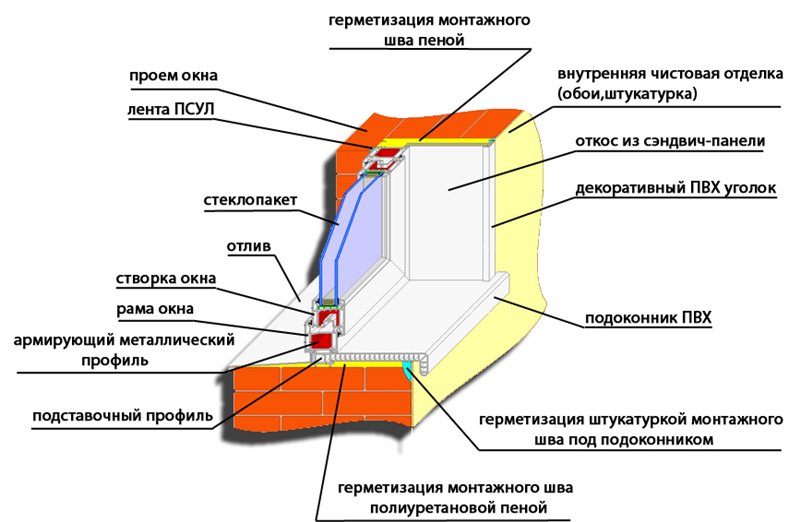

In general, the window includes a windowframe, sashes with glass (double-glazed windows), window sill and accessories. The window frame is the frame of the window and is fixed in the wall opening. On it, the doors are fastened through the fittings, and from the bottom it is combined with the sill.  Construction of a plastic window. The leaflets of the windows contain a glass element (glass or double-glazed), fixed with a bezel, and accessories for fastening to the frame and locking hardware. The valves can be movable or fixed. Fixed doors are manufactured together with the frame and do not have accessories. The movable flaps are connected to the frame via hinge elements. Valves can have different degrees of tightness and thermal insulation. Based on the required thermal protection, the flaps can have one sheet of glass or several (usually two) layers. In the sealed windows, double-glazed windows are installed in the shutters, which are several windows, with sealant composition at their ends. A window sill is an additional element, installed from the bottom of the frame. It has the form of a board of the desired thickness and width, the length equal to the length of the frame. Modern windows are made of plastic, wood, light metals or composite materials (plastic - metal). The largest application in private homes are plastic and wooden windows. Back to contents</a>

Construction of a plastic window. The leaflets of the windows contain a glass element (glass or double-glazed), fixed with a bezel, and accessories for fastening to the frame and locking hardware. The valves can be movable or fixed. Fixed doors are manufactured together with the frame and do not have accessories. The movable flaps are connected to the frame via hinge elements. Valves can have different degrees of tightness and thermal insulation. Based on the required thermal protection, the flaps can have one sheet of glass or several (usually two) layers. In the sealed windows, double-glazed windows are installed in the shutters, which are several windows, with sealant composition at their ends. A window sill is an additional element, installed from the bottom of the frame. It has the form of a board of the desired thickness and width, the length equal to the length of the frame. Modern windows are made of plastic, wood, light metals or composite materials (plastic - metal). The largest application in private homes are plastic and wooden windows. Back to contents</a>

General principles of installing windows

The scheme for dismantling the old window. Installation of the window is made in a specially made window opening in the wall of the house. It is the shape and size of the window opening that determines the shape and size of the window frame. The most characteristic is the rectangular shape. The number, type, size, location of the wings, complete set of accessories completely depend on the desire of the consumer. The nature of the installation is largely determined by the material from which the window is made and the material from which the wall is made (to a lesser extent). When installing windows in wooden log houses, it is necessary to take into account the draft of the wall, which can last for more than a year. In this case, you need to use an additional window box that does not allow you to crush the window frame. An important condition for a quality window installation is the preservation of thermal protection and protection from moisture. Window joints and walls, fastening elements should not reduce these characteristics, should not form thermal bridges and channels for the penetration of moisture into the house. A natural requirement is the mechanical strength of the fastening of windows, which can withstand any gusts of wind, etc. Back to contents</a>

The scheme for dismantling the old window. Installation of the window is made in a specially made window opening in the wall of the house. It is the shape and size of the window opening that determines the shape and size of the window frame. The most characteristic is the rectangular shape. The number, type, size, location of the wings, complete set of accessories completely depend on the desire of the consumer. The nature of the installation is largely determined by the material from which the window is made and the material from which the wall is made (to a lesser extent). When installing windows in wooden log houses, it is necessary to take into account the draft of the wall, which can last for more than a year. In this case, you need to use an additional window box that does not allow you to crush the window frame. An important condition for a quality window installation is the preservation of thermal protection and protection from moisture. Window joints and walls, fastening elements should not reduce these characteristics, should not form thermal bridges and channels for the penetration of moisture into the house. A natural requirement is the mechanical strength of the fastening of windows, which can withstand any gusts of wind, etc. Back to contents</a>

Preparing for the installation of plastic windows

Before installing a plastic window, you mustto fill the irregularities of the window opening. Plastic windows are usually ordered in person, as they can have a variety of sizes and equipment. Preparatory work begins with the measurement of the desired window. For this purpose, the height and width of the window opening is measured. If the window opening has deviations in the part of the sides, the dimension is measured by the smallest distance between the opposite sides of the opening. The length of the frame of the plastic window is defined as the width of the window opening minus 30 mm. The recommended clearance of 15 mm on each side of the frame is necessary for foam filling during installation. Similarly, the height of the window frame is determined, but in addition it is necessary to subtract the thickness of the window sill (usually 40 mm), which will be installed at the bottom of the opening. The thickness of the frame is determined on the basis that it is fixed not at the level of the face of the wall, but, as a rule, it becomes deeper by about a third of the thickness of the opening. When determining the length of the window sill, the dimensions of the gaps are not taken into account, and the width is at the discretion of the customer. Preparing the window opening for the window installation includes cleaning its surface from all irregularities. If there are significant distortions, try to correct the situation with cement mortar or putty. If there are local significant irregularities, they should be removed using a bit or a Bulgarian. It is most important to ensure that the walls of the aperture are horizontal, with horizontal level being checked by level. If a small skew of the vertical walls during installation of the window can be eliminated by mounting foam, then the slightest defect of the horizontal walls leads to a skew of the whole window. The plastic window usually comes in assembled form. To install it in the window opening, it is necessary to disassemble the window, namely: remove the movable doors, then remove the glazing beads and pull out the double-glazed windows from the movable doors, the same is done on the fixed doors that are fixed to the frame. Back to contents</a>

Before installing a plastic window, you mustto fill the irregularities of the window opening. Plastic windows are usually ordered in person, as they can have a variety of sizes and equipment. Preparatory work begins with the measurement of the desired window. For this purpose, the height and width of the window opening is measured. If the window opening has deviations in the part of the sides, the dimension is measured by the smallest distance between the opposite sides of the opening. The length of the frame of the plastic window is defined as the width of the window opening minus 30 mm. The recommended clearance of 15 mm on each side of the frame is necessary for foam filling during installation. Similarly, the height of the window frame is determined, but in addition it is necessary to subtract the thickness of the window sill (usually 40 mm), which will be installed at the bottom of the opening. The thickness of the frame is determined on the basis that it is fixed not at the level of the face of the wall, but, as a rule, it becomes deeper by about a third of the thickness of the opening. When determining the length of the window sill, the dimensions of the gaps are not taken into account, and the width is at the discretion of the customer. Preparing the window opening for the window installation includes cleaning its surface from all irregularities. If there are significant distortions, try to correct the situation with cement mortar or putty. If there are local significant irregularities, they should be removed using a bit or a Bulgarian. It is most important to ensure that the walls of the aperture are horizontal, with horizontal level being checked by level. If a small skew of the vertical walls during installation of the window can be eliminated by mounting foam, then the slightest defect of the horizontal walls leads to a skew of the whole window. The plastic window usually comes in assembled form. To install it in the window opening, it is necessary to disassemble the window, namely: remove the movable doors, then remove the glazing beads and pull out the double-glazed windows from the movable doors, the same is done on the fixed doors that are fixed to the frame. Back to contents</a>

Installation of a frame of a plastic window

The scheme of installation of a plastic window in an aperture. The installation of the plastic window begins with the installation of the frame together with the fixed doors. First, the production profile is established, which is horizontally aligned, by placing under it temporary pads underneath. If such a profile is not included in the box, the installation begins immediately with the installation of the frame, while it is leveled and the necessary clearance for the sill is taken into account. Before installing the frame in the opening, fix the fasteners. It is recommended to use anchor plates. They are fixed at a distance of up to 20 cm from the corner of the frame on both sides. For fixing, screws up to 10 cm long are used, which are screwed into the dowel not to the end. Preliminary for dowels drilled holes. In the wall of the window opening, a recess is made for the fastening plate and anchor fasteners. Then all the fastening is cemented in the wall with cement mortar. The frame is installed in the opening and is adjusted vertically and horizontally. At the same time for alignment use not completely screwed screws. In addition, wooden pads are placed where necessary. It is recommended not to remove the protective film from the window elements until the installation is finished, so as not to contaminate them. The gap between the frame and the wall must be filled with a mounting foam. It is important to ensure uniformity and tightness of the mass after curing. If the gap exceeds 2 cm, then foam filling is performed in several stages. To improve the adhesion of foam to the wall, it is recommended to pre-wet the surface with a sprayer. The drying time of the foam is 10-12 hours, during which it must be protected from direct sunlight. Back to contents</a>

The scheme of installation of a plastic window in an aperture. The installation of the plastic window begins with the installation of the frame together with the fixed doors. First, the production profile is established, which is horizontally aligned, by placing under it temporary pads underneath. If such a profile is not included in the box, the installation begins immediately with the installation of the frame, while it is leveled and the necessary clearance for the sill is taken into account. Before installing the frame in the opening, fix the fasteners. It is recommended to use anchor plates. They are fixed at a distance of up to 20 cm from the corner of the frame on both sides. For fixing, screws up to 10 cm long are used, which are screwed into the dowel not to the end. Preliminary for dowels drilled holes. In the wall of the window opening, a recess is made for the fastening plate and anchor fasteners. Then all the fastening is cemented in the wall with cement mortar. The frame is installed in the opening and is adjusted vertically and horizontally. At the same time for alignment use not completely screwed screws. In addition, wooden pads are placed where necessary. It is recommended not to remove the protective film from the window elements until the installation is finished, so as not to contaminate them. The gap between the frame and the wall must be filled with a mounting foam. It is important to ensure uniformity and tightness of the mass after curing. If the gap exceeds 2 cm, then foam filling is performed in several stages. To improve the adhesion of foam to the wall, it is recommended to pre-wet the surface with a sprayer. The drying time of the foam is 10-12 hours, during which it must be protected from direct sunlight. Back to contents</a>

Window sill mounting

The scheme of installation of a plastic window sill. At the next stage of the installation of the window, you should make the window sill yourself. At first, the length of the window sill is finally checked and cut off. The window sill is squeezed into the space between the installation profile and the wall of the opening; if the profile is missing - between the frame and the opening. Pre-installed on the ends of the window sill are stubs. Clearances between the frame and the window sill, as well as between the window sill and the wall, are filled with mounting foam. On the windowsill, to avoid deformation from the expansion of the foam, you should install the load. Back to contents</a>

The scheme of installation of a plastic window sill. At the next stage of the installation of the window, you should make the window sill yourself. At first, the length of the window sill is finally checked and cut off. The window sill is squeezed into the space between the installation profile and the wall of the opening; if the profile is missing - between the frame and the opening. Pre-installed on the ends of the window sill are stubs. Clearances between the frame and the window sill, as well as between the window sill and the wall, are filled with mounting foam. On the windowsill, to avoid deformation from the expansion of the foam, you should install the load. Back to contents</a>

Mounting slopes on plastic windows

Initially around the perimeter of the frame are removedsurpluses of cured mounting foam. Window slopes are made of three plastic (PVC) panels, cut to the size of the frame. Fastening of slopes is carried out with the help of mounting foam. While the foam hardens, temporary fastening of the slopes can be done with a paint tape. The final frame is formed by an F-shaped profile, which is inserted between the bar and the wall. Back to contents</a>

Installing window leaflets

Scheme of mounting the ebb to the frame. After installing the window frame, the queue reaches the installation of the movable flaps. They are mounted on the corresponding hinge elements. Double-glazed windows are installed first in the fixed wings, and then into the movable ones. Fastening of double-glazed windows is carried out by glazing beads. And at first, short beads are installed, and then long ones. Their final fixation can be done with a rubber hammer. To protect the joints, it is recommended to overlay the inner and outer side of the protective tape with a sticky layer. On the inside, a special waterproof tape is used, and on the outside - a vapor-permeable tape. From the bottom of the frame it is desirable to use a protective tape with a foil coating. Back to contents</a>

Scheme of mounting the ebb to the frame. After installing the window frame, the queue reaches the installation of the movable flaps. They are mounted on the corresponding hinge elements. Double-glazed windows are installed first in the fixed wings, and then into the movable ones. Fastening of double-glazed windows is carried out by glazing beads. And at first, short beads are installed, and then long ones. Their final fixation can be done with a rubber hammer. To protect the joints, it is recommended to overlay the inner and outer side of the protective tape with a sticky layer. On the inside, a special waterproof tape is used, and on the outside - a vapor-permeable tape. From the bottom of the frame it is desirable to use a protective tape with a foil coating. Back to contents</a>

Features of installation of wooden windows

The installation of windows from a tree is somewhat different frominstallation of plastic windows. The advantage of the tree is the simplicity of fitting the size. At skewed openings, in the places of constriction, the wooden frame is trimmed to the desired size. This property is used when you need to install a window in a wooden house. The size of the wooden window is selected according to the maximum size of the window opening without gaps.  Drawing of a wooden window. Installation of a wooden window in a concrete wall usually begins with a window sill. With the help of cement mortar, it is completely horizontal. The window sill is fastened with 5-6 dowels. Next, a frame is installed, from which the movable doors are removed. The most common option for installing a window frame is to mount it on the pads. As the pads used pieces of boards or slats up to 15 cm wide, one edge of which is mowed in the form of a wedge. First, loose support pads are installed on one side of the frame, then the spacer pins are driven from the opposite side by a wedge. The pads are fixed with silicone. Clearances are filled with foam. Mounting of the frame to the wall is carried out by an anchor method or by a passage, i.e. sewing a frame through a long dowel or a screw. The distance between the fasteners is recommended 50-60 cm. When installing a wooden frame, it is necessary to take into account the high moisture absorption of wood. The lateral end of the window requires additional reliable insulation from moisture. For this, a layer of roofing material is used. Slopes, both external and internal, are formed from a cement slurry; The slope completely covers the seam between the window and the wall, it usually goes to the window frame. The wooden frame does not have sealing elements, which are installed in plastic windows. When installing wooden windows with their own hands, it is necessary to take measures to protect them from moisture penetration through the doors. The contact area of the glass with the tree is smeared with silicone around the entire perimeter of the leaf. After fixing the glass with a glazing bead, all gaps are filled with sealing putty. Back to contents</a>

Drawing of a wooden window. Installation of a wooden window in a concrete wall usually begins with a window sill. With the help of cement mortar, it is completely horizontal. The window sill is fastened with 5-6 dowels. Next, a frame is installed, from which the movable doors are removed. The most common option for installing a window frame is to mount it on the pads. As the pads used pieces of boards or slats up to 15 cm wide, one edge of which is mowed in the form of a wedge. First, loose support pads are installed on one side of the frame, then the spacer pins are driven from the opposite side by a wedge. The pads are fixed with silicone. Clearances are filled with foam. Mounting of the frame to the wall is carried out by an anchor method or by a passage, i.e. sewing a frame through a long dowel or a screw. The distance between the fasteners is recommended 50-60 cm. When installing a wooden frame, it is necessary to take into account the high moisture absorption of wood. The lateral end of the window requires additional reliable insulation from moisture. For this, a layer of roofing material is used. Slopes, both external and internal, are formed from a cement slurry; The slope completely covers the seam between the window and the wall, it usually goes to the window frame. The wooden frame does not have sealing elements, which are installed in plastic windows. When installing wooden windows with their own hands, it is necessary to take measures to protect them from moisture penetration through the doors. The contact area of the glass with the tree is smeared with silicone around the entire perimeter of the leaf. After fixing the glass with a glazing bead, all gaps are filled with sealing putty. Back to contents</a>

Necessary materials and tools

When installing the window on its own, standard specialized materials should be used to ensure reliable fastening and protection. The following materials are recommended:  The scheme of installation of a wooden window.

The scheme of installation of a wooden window.

- mounting foam professional, intended for use in assembly pistols (sold in cans);

- a permeable tape with a sticky layer;

- Hydraulically sealed tape with an adhesive layer;

- tape with a layer of foil and an adhesive layer;

- Screws (self-tapping screws) for construction with metal up to 120 mm in length, 6 mm in diameter;

- construction wedges.

Installing windows with your own hands requires the use of the following tools:

- Assembling gun;

- Bulgarian;

- Sander;

- Screwdriver;

- electric drill;

- level;

- plumb bob;

- a spray for water;

- chisel;

- a hammer;

- a rubber hammer;

- scissors;

- knife;

- pliers;

- screwdriver;

- roulette;

- line meter.

Installing windows with your own hands is a painstaking task, requiring certain skills and accuracy. At the same time, virtually any person can install the window independently.