Almost everyone agrees that afterwork day will be pleasant to relax, and the rocking chair will help in this. They want to have everything in an apartment, a house or a dacha, but not everyone can buy it. Often in furniture stores and stores, the price of such a thing, due to the traditionally high popularity and, accordingly, demand, is unjustifiably overstated. Meanwhile, it is worthwhile to know that the rocking chair with its own hands is quite easy to make. You just need to choose the right material, and making your own drawings of such an object will not be very difficult.  The scheme of the device of a rocking chair.

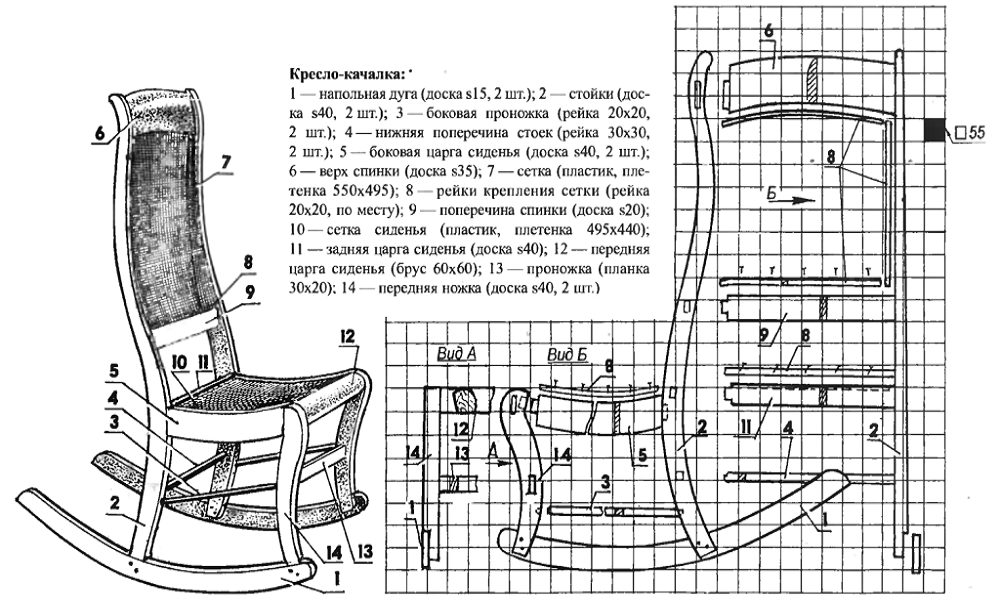

The scheme of the device of a rocking chair.

Materials used to manufacture the rocking chair

Such an armchair can be made from woodan array of plywood, metal or artificial rattan. Each of these materials has its own advantages and disadvantages. To this we need to add the possibility of access to various tools and the possession of various working skills. The role of an armchair for an indoor room or for open air also plays a serious role. Metal is the most suitable material for the implementation of such a design.  Drawing of rocking chair. It has maximum strength under various types of loads, at the same time is durable and does not require special storage conditions. But to work with it you need to know the welding process and access to the welding machine, and also it is desirable to have an autogenous apparatus, since it is quite difficult to bend the skids on a cold one. The design as a result will be quite weighty, so the metal is best suited for a street version. Making furniture from artificial rattan requires very specific skills in the field of weaving, and the material is quite expensive and not always available, although the chair itself results in an easy and at the same time durable and durable. The most accessible and simple in processing of materials is a tree. To create a rocking chair from a wood massif, optimal species are oak, larch, pine or other coniferous species. The drawing is very similar to the usual stationary chair. However, the runners will have to buckle on the steam bath, which requires certain knowledge and skills. The application for the production of thick plywood will also help to avoid this complexity, so it is best to use it for the independent production of a rocking chair. Back to contents</a>

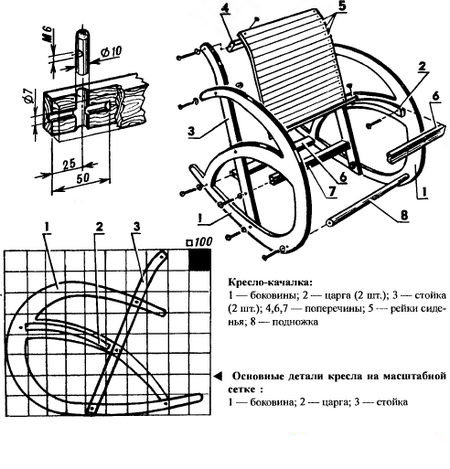

Drawing of rocking chair. It has maximum strength under various types of loads, at the same time is durable and does not require special storage conditions. But to work with it you need to know the welding process and access to the welding machine, and also it is desirable to have an autogenous apparatus, since it is quite difficult to bend the skids on a cold one. The design as a result will be quite weighty, so the metal is best suited for a street version. Making furniture from artificial rattan requires very specific skills in the field of weaving, and the material is quite expensive and not always available, although the chair itself results in an easy and at the same time durable and durable. The most accessible and simple in processing of materials is a tree. To create a rocking chair from a wood massif, optimal species are oak, larch, pine or other coniferous species. The drawing is very similar to the usual stationary chair. However, the runners will have to buckle on the steam bath, which requires certain knowledge and skills. The application for the production of thick plywood will also help to avoid this complexity, so it is best to use it for the independent production of a rocking chair. Back to contents</a>

Technology of creating a chair rocking chair made of wood

Rocking chair assembly diagram.The design schemes of such a chair are divided into two main types: if the seat on a separate frame is installed on curved runners and if the runners themselves serve as the frame of such a seat. Based on this, the material is selected. Before you start, you need to transfer the drawing to a large sheet of paper at a scale of 1 to 1. Old wallpaper is fine. Of the tools, you will need a jigsaw or at least a hand saw for wood, an electric drill, a screwdriver or a screwdriver and self-tapping screws, and preferably wood glue. Within the framework of one structure, it is best to combine wooden planks, beams and plywood. The details of the structure cut out of paper are laid out on the material and outlined with a pencil. 18 strips of 54 x 3 cm for the backrest and 16 strips for the seat measuring 50 x 3 cm are cut out of 1 cm thick plywood.Then two pieces for the base of the seat and the back are cut from 4 mm thick plywood. After sanding, strips 1 cm thick are glued onto a 4 mm thick base. For this, PVA glue is best suited. The result is a curved shape. The surface of the seat must be perpendicular to the end of the curved parts at the front of the seat. The center of gravity should be directly over the very center of the bend. Backward, it should continue at least a third longer than forward, since when swinging, the main effort goes exactly there. The uprights for the seat frame are assembled from a wooden bar with a thickness of 15 by 15 or 15 by 20 mm using a spike connection or self-tapping screws, preferably with additional gluing of the joints. Their heads recessed into the wood must be closed with wooden corks and covered with putty. If the seat is covered with a casing, then it can also be cut out of plywood, and if not, then it can be recruited from planks at intervals of 10-15 mm. The best mounting method for them would be on self-tapping screws 25-30 mm long. In order for the rocking chair to serve for a long enough time, before assembling wooden parts into a single structure, they must be impregnated with a composition that prevents decay. After that, they can already be stained or painted. A similar procedure will be very appropriate for metal, which must be lubricated with an anti-corrosion coating before painting. After the manufacture and processing of parts, it will not be difficult to assemble a rocking chair from them yourself.

Rocking chair assembly diagram.The design schemes of such a chair are divided into two main types: if the seat on a separate frame is installed on curved runners and if the runners themselves serve as the frame of such a seat. Based on this, the material is selected. Before you start, you need to transfer the drawing to a large sheet of paper at a scale of 1 to 1. Old wallpaper is fine. Of the tools, you will need a jigsaw or at least a hand saw for wood, an electric drill, a screwdriver or a screwdriver and self-tapping screws, and preferably wood glue. Within the framework of one structure, it is best to combine wooden planks, beams and plywood. The details of the structure cut out of paper are laid out on the material and outlined with a pencil. 18 strips of 54 x 3 cm for the backrest and 16 strips for the seat measuring 50 x 3 cm are cut out of 1 cm thick plywood.Then two pieces for the base of the seat and the back are cut from 4 mm thick plywood. After sanding, strips 1 cm thick are glued onto a 4 mm thick base. For this, PVA glue is best suited. The result is a curved shape. The surface of the seat must be perpendicular to the end of the curved parts at the front of the seat. The center of gravity should be directly over the very center of the bend. Backward, it should continue at least a third longer than forward, since when swinging, the main effort goes exactly there. The uprights for the seat frame are assembled from a wooden bar with a thickness of 15 by 15 or 15 by 20 mm using a spike connection or self-tapping screws, preferably with additional gluing of the joints. Their heads recessed into the wood must be closed with wooden corks and covered with putty. If the seat is covered with a casing, then it can also be cut out of plywood, and if not, then it can be recruited from planks at intervals of 10-15 mm. The best mounting method for them would be on self-tapping screws 25-30 mm long. In order for the rocking chair to serve for a long enough time, before assembling wooden parts into a single structure, they must be impregnated with a composition that prevents decay. After that, they can already be stained or painted. A similar procedure will be very appropriate for metal, which must be lubricated with an anti-corrosion coating before painting. After the manufacture and processing of parts, it will not be difficult to assemble a rocking chair from them yourself.