It is not that difficult to make a plasterboard ceiling with your own hands. Plasterboard ceilings are in great demandpopular, as they allow you to transform the interior of any room beyond recognition. It is also called a suspended ceiling - it is most often performed in one level and is quite easy to install.

Plasterboard ceilings are in great demandpopular, as they allow you to transform the interior of any room beyond recognition. It is also called a suspended ceiling - it is most often performed in one level and is quite easy to install.

Why to mount ceilings it is convenient to choose drywall

With a material like plasterboard, you can nottake care of careful leveling of the base. Conventional methods of leveling with various building mixtures are not only quite labor-intensive, but also do not always lead to the desired result. Plasterboard has a flexible structure, due towhich allows you to create various structures. With the help of plasterboard sheets, you can easily hide utility elements from view, such as pipes, beams, wires and others. You can arrange beautiful and original lighting structures, choose a design of any shape, sometimes ceilings are arranged in several levels with a variety of lighting. Plasterboard structures are not particularly heavy. When installing the ceiling, you can also arrange thermal insulation, sound insulation. Another plus: after the ceiling structure is installed in place, you do not need to wait for the surface to dry. The disadvantages can be listed as follows:

Plasterboard has a flexible structure, due towhich allows you to create various structures. With the help of plasterboard sheets, you can easily hide utility elements from view, such as pipes, beams, wires and others. You can arrange beautiful and original lighting structures, choose a design of any shape, sometimes ceilings are arranged in several levels with a variety of lighting. Plasterboard structures are not particularly heavy. When installing the ceiling, you can also arrange thermal insulation, sound insulation. Another plus: after the ceiling structure is installed in place, you do not need to wait for the surface to dry. The disadvantages can be listed as follows:

When doing the work yourself, ceilings are made ofgypsum plasterboard is installed more often than tension plasterboard. At home, it is not always possible to provide the canvas with even tension, but in the case of using gypsum plasterboard sheets, this problem does not arise. However, this material cannot be given either a clearly positive or negative recommendation. It is better to make a choice depending on the conditions of a particular room. Return to contents</a>

Materials, tools

The most common method for installing a ceiling is considered to be a single-level one with direct hangers. To install a ceiling structure, you will need: Tools for working with plasterboard.

Tools for working with plasterboard.

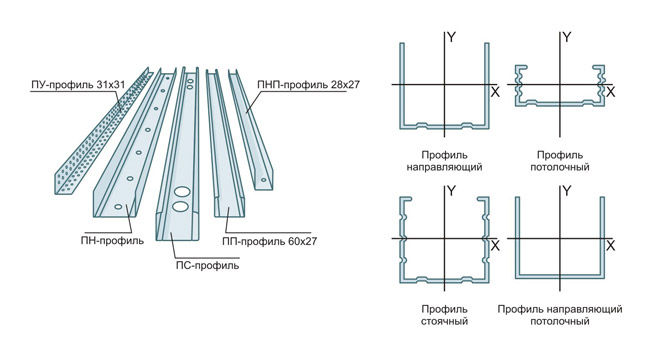

- guide profiles PN 28X27 mm;

- ceiling profiles PP 60X27 mm;

- anchor wedges;

- sealing tape;

- special dowel-nails;

- cord;

- level;

- rule;

- drywall;

- ribbon-serpyanka;

- putty mix for joints;

- a hammer;

- roulette;

- stationery knife;

- Screwdriver;

- perforator;

- self-tapping screws with press washers;

- self-tapping screws for metal;

- direct suspensions;

- connectors CRAB;

- a primer based on acrylic;

- scissors for cutting metal;

- heat-insulating, soundproof materials;

- spatulas.

Profiles for plasterboard.In building materials stores, when buying hangers and profiles, you should not save on the quality of these products. In order to, it is better to buy good quality materials than to constantly experience inconvenience during operation. The water level is a pair of flasks filled with water, which are connected to each other by a thin tube. Its operating principle is based on the law of physics about communicating vessels, so the horizontal marking made with its use is obtained with great accuracy. To make a plasterboard ceiling with your own hands, using such a level is much more convenient than other types. For example, a bubble level does not allow you to make markings with the same accuracy. Working with a water level is that marks are put on the corners, then they are connected using a cord-beater. There are a great many types of plasterboard sheets. But to install the ceiling, you will have to choose from only two - simple or waterproof. A material with increased resistance to moisture is used in bathrooms or kitchens, i.e. where the humidity is constantly changing. Such performance characteristics are achieved by introducing various hydrophobic additives into the gypsum during production. These types differ from each other primarily in appearance - in color. Simple gypsum board is a regular gray color, while moisture-resistant gypsum board is greenish. Most often, 9.5 mm thick gypsum board is used for ceilings. Sealing tape is necessary so that the frame is pressed more tightly to the supporting structures. It is highly undesirable to neglect its use. Return to contents</a>

Profiles for plasterboard.In building materials stores, when buying hangers and profiles, you should not save on the quality of these products. In order to, it is better to buy good quality materials than to constantly experience inconvenience during operation. The water level is a pair of flasks filled with water, which are connected to each other by a thin tube. Its operating principle is based on the law of physics about communicating vessels, so the horizontal marking made with its use is obtained with great accuracy. To make a plasterboard ceiling with your own hands, using such a level is much more convenient than other types. For example, a bubble level does not allow you to make markings with the same accuracy. Working with a water level is that marks are put on the corners, then they are connected using a cord-beater. There are a great many types of plasterboard sheets. But to install the ceiling, you will have to choose from only two - simple or waterproof. A material with increased resistance to moisture is used in bathrooms or kitchens, i.e. where the humidity is constantly changing. Such performance characteristics are achieved by introducing various hydrophobic additives into the gypsum during production. These types differ from each other primarily in appearance - in color. Simple gypsum board is a regular gray color, while moisture-resistant gypsum board is greenish. Most often, 9.5 mm thick gypsum board is used for ceilings. Sealing tape is necessary so that the frame is pressed more tightly to the supporting structures. It is highly undesirable to neglect its use. Return to contents</a>

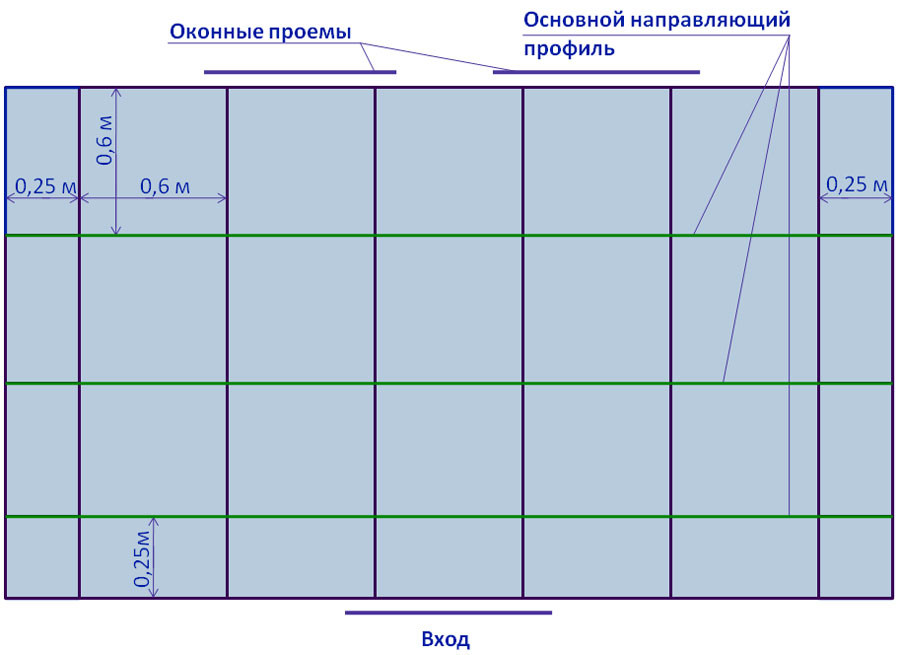

How to make a marking, mounting rails

Ceiling layout diagram.Once the walls are plastered, you can proceed to installing the ceiling structure. First, determine which corner of the room is the lowest. To do this, take a tape measure, measure the distance from the floor to the ceiling in each corner. Do the same in the center of the room - the ceiling may sag. When you find the lowest corner, step back a certain distance from it: if you plan to install built-in lights, this is 8 cm; if they are not going to be installed, this is 5 cm. Put a mark at this distance and from it, using a water level, measure a horizontal line to each corner. The marks must be connected using a beating cord. Here you will need to involve an assistant - together you need to properly stretch the cord between the marks on one wall, then pull it with your free hand and release it sharply. Having hit the wall surface with force, the cord leaves a mark on it. Repeat the same operation for each of the walls. Now you can fix the guide profiles on the walls. The product is applied to the wall so that its bottom coincides with the marking line. Take a marker and mark the places for fasteners using the holes made in the profile. If the holes in the profile itself are made far from the edge, additional holes should be made using a hammer drill. The next step is to drill holes in the marked places. A sealing tape is glued to the side of the profile that will lean against the wall. Apply the profile to the line again and fix it with dowel nails. At least three fastening points must be made for one product. Now you need to mark the axes of the main profiles - these are those that are attached with hangers to . It is more logical to distribute them across the room - this way they will not have to be extended. If the plasterboard sheet is 1.2 m wide, the profiles must be spaced approximately three times smaller. With such a step of the main guides, the bearing ones will only be needed at the transverse joints of the sheets. To perform the marking, you need to take the hanger, attach it to the ceiling at the right points, and use a marker to mark the places for drilling holes for the anchor wedges. There should be at least a couple of them per hanger. Return to the table of contents</a>

Ceiling layout diagram.Once the walls are plastered, you can proceed to installing the ceiling structure. First, determine which corner of the room is the lowest. To do this, take a tape measure, measure the distance from the floor to the ceiling in each corner. Do the same in the center of the room - the ceiling may sag. When you find the lowest corner, step back a certain distance from it: if you plan to install built-in lights, this is 8 cm; if they are not going to be installed, this is 5 cm. Put a mark at this distance and from it, using a water level, measure a horizontal line to each corner. The marks must be connected using a beating cord. Here you will need to involve an assistant - together you need to properly stretch the cord between the marks on one wall, then pull it with your free hand and release it sharply. Having hit the wall surface with force, the cord leaves a mark on it. Repeat the same operation for each of the walls. Now you can fix the guide profiles on the walls. The product is applied to the wall so that its bottom coincides with the marking line. Take a marker and mark the places for fasteners using the holes made in the profile. If the holes in the profile itself are made far from the edge, additional holes should be made using a hammer drill. The next step is to drill holes in the marked places. A sealing tape is glued to the side of the profile that will lean against the wall. Apply the profile to the line again and fix it with dowel nails. At least three fastening points must be made for one product. Now you need to mark the axes of the main profiles - these are those that are attached with hangers to . It is more logical to distribute them across the room - this way they will not have to be extended. If the plasterboard sheet is 1.2 m wide, the profiles must be spaced approximately three times smaller. With such a step of the main guides, the bearing ones will only be needed at the transverse joints of the sheets. To perform the marking, you need to take the hanger, attach it to the ceiling at the right points, and use a marker to mark the places for drilling holes for the anchor wedges. There should be at least a couple of them per hanger. Return to the table of contents</a>

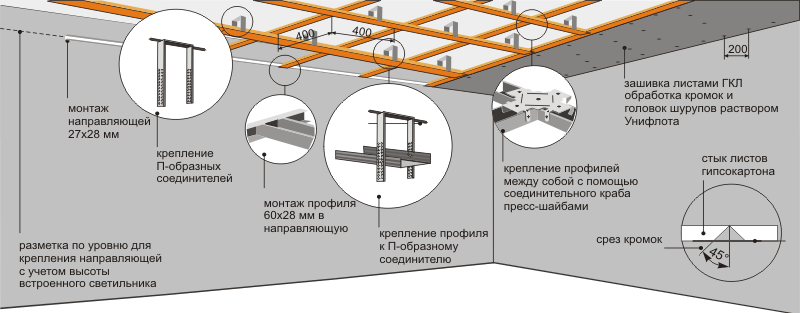

How to install a ceiling frame

The hangers should be secured when they are completelydust settles. They must first be sealed with a sealant. Fasten the hangers to the anchor wedges and pull their ends down. They should not bend when the main profiles are attached to them. Scheme of installation of profiles on the ceiling.Let's move on to installing the main profiles. If the room is less than 3 m wide, cut them to the required size, subtracting another 1 cm. After that, you need to insert all the elements into the guides. If the room is wide, each profile must be extended so that the resulting element is shorter than this value by 1 cm. The hangers must be distributed closer to the edges of the extension element. Distribute the connections so that they are not on the same line on adjacent profiles. To do this, first place the long profile in one row, and for the next row - first the short part. Profiles are attached to the hangers from the corners of the room. If you are working with an assistant, it will be easier for him to work with a rule. The tool must be pressed against the elements that form the corner, and the ceiling profile must be supported so that it is level with the guides. In this position, it must be attached to the hanger, for this, two screws are screwed in on both sides. The excess length of the hangers should be bent upwards or simply cut off. Control the process using a two-meter level. The second profile is fixed in the same way, supported only by the guides. After that, move on to the next side, again arrange two ceiling profiles. You can stretch the cord and set the profiles along it. But remember that sagging of the cord is also possible, and it is difficult to hold the element due to the vibration of the screwdriver. The next step is to hang single-level connecting elements, the crab, on the places where the profiles are supposed to be joined. They are fastened with self-tapping screws, two pieces on one side. If the ceiling is lowered slightly, it should be taken into account that the crabs will have to be inserted into the main profiles before installation. Having strengthened the connectors, cut the supporting profiles and insert them into them, fix them with self-tapping screws. Return to the table of contents</a>

Scheme of installation of profiles on the ceiling.Let's move on to installing the main profiles. If the room is less than 3 m wide, cut them to the required size, subtracting another 1 cm. After that, you need to insert all the elements into the guides. If the room is wide, each profile must be extended so that the resulting element is shorter than this value by 1 cm. The hangers must be distributed closer to the edges of the extension element. Distribute the connections so that they are not on the same line on adjacent profiles. To do this, first place the long profile in one row, and for the next row - first the short part. Profiles are attached to the hangers from the corners of the room. If you are working with an assistant, it will be easier for him to work with a rule. The tool must be pressed against the elements that form the corner, and the ceiling profile must be supported so that it is level with the guides. In this position, it must be attached to the hanger, for this, two screws are screwed in on both sides. The excess length of the hangers should be bent upwards or simply cut off. Control the process using a two-meter level. The second profile is fixed in the same way, supported only by the guides. After that, move on to the next side, again arrange two ceiling profiles. You can stretch the cord and set the profiles along it. But remember that sagging of the cord is also possible, and it is difficult to hold the element due to the vibration of the screwdriver. The next step is to hang single-level connecting elements, the crab, on the places where the profiles are supposed to be joined. They are fastened with self-tapping screws, two pieces on one side. If the ceiling is lowered slightly, it should be taken into account that the crabs will have to be inserted into the main profiles before installation. Having strengthened the connectors, cut the supporting profiles and insert them into them, fix them with self-tapping screws. Return to the table of contents</a>

How to attach a plasterboard to the frame

Installation diagram for a single-level suspended ceiling.Before installation, the plasterboard sheets should be left to rest for a couple of days in the room where they will be installed. Fastening should be done from the corner, observing a step of 17 cm for the screws. On adjacent sheets, they should be staggered. Step back 10 mm from the edge of the sheet, the heads of the screws should be slightly countersunk, but at the same time make sure that the elements do not pierce the plasterboard. The sheets of material are sewn staggered approximately by the step of the main profiles, which is 40.2 cm. It is better to leave small gaps of 2 mm between them, the same - between the wall and the edge of the sheet. The next step is to putty the seams formed between the sheets. Before sealing the seams, they must be primed and completely dried. Choose a stronger putty, when mixing, follow the manufacturer's instructions on the package. Fill all the seams and holes made by the screws with the mixture. When the putty has set a little, cover the seams with reinforcing tape and cover it again with putty mixture. Such a surface is almost ready for finishing. You can also insure yourself against cracks on the ceiling. To do this, use painter's fiberglass - it is glued to the prepared, puttied area, puttied again, after which it is painted or finished.

Installation diagram for a single-level suspended ceiling.Before installation, the plasterboard sheets should be left to rest for a couple of days in the room where they will be installed. Fastening should be done from the corner, observing a step of 17 cm for the screws. On adjacent sheets, they should be staggered. Step back 10 mm from the edge of the sheet, the heads of the screws should be slightly countersunk, but at the same time make sure that the elements do not pierce the plasterboard. The sheets of material are sewn staggered approximately by the step of the main profiles, which is 40.2 cm. It is better to leave small gaps of 2 mm between them, the same - between the wall and the edge of the sheet. The next step is to putty the seams formed between the sheets. Before sealing the seams, they must be primed and completely dried. Choose a stronger putty, when mixing, follow the manufacturer's instructions on the package. Fill all the seams and holes made by the screws with the mixture. When the putty has set a little, cover the seams with reinforcing tape and cover it again with putty mixture. Such a surface is almost ready for finishing. You can also insure yourself against cracks on the ceiling. To do this, use painter's fiberglass - it is glued to the prepared, puttied area, puttied again, after which it is painted or finished.