An important role in the interior of a house or apartmentplays the ceiling. Recently, the technology of making plasterboard ceilings has become increasingly popular. And this is no coincidence, because this material allows you to create a truly unique ceiling design depending on the imagination and wishes of the owners in a fairly short time. In addition to truly limitless design possibilities, a plasterboard ceiling allows you to hide the shortcomings and defects of the ceilings without much expense and labor-intensive work. Plasterboard ceiling offers countlessnumber of design options, and also allows you to hide the defects of the ceiling. There can be several versions of plasterboard ceilings: single-level, multi-level, with lighting using a traditional chandelier or combined, using LED lighting and spotlights. Many people decide to install . For a person who has basic repair skills, has a reserve of patience and desire, this process will not cause any particular difficulties.

Plasterboard ceiling offers countlessnumber of design options, and also allows you to hide the defects of the ceiling. There can be several versions of plasterboard ceilings: single-level, multi-level, with lighting using a traditional chandelier or combined, using LED lighting and spotlights. Many people decide to install . For a person who has basic repair skills, has a reserve of patience and desire, this process will not cause any particular difficulties.

What to consider when developing a design

When planning a ceiling renovation, you cancontact professionals to develop a ceiling design. Or, having studied visual materials (magazines, the Internet), let your imagination run wild and design a plasterboard ceiling design yourself. First of all, you need to proceed from the purpose of the room, its possible division into zones, the general style, and you also need to determine the required level of illumination. Sketch of a plasterboard ceiling.You can make a ceiling with your own hands in any room, with the exception of perhaps the bathroom (high humidity in the room will not have a very good effect on this material). Even small rooms with low ceilings can be transformed thanks to the original design. However, it is necessary to take into account that due to the installation of plasterboard ceilings, the height will be noticeably reduced. In this case, will come to the rescue, in the niches of which it is possible to place lighting and thereby reduce to nothing some of the disadvantages, increase the volume and provide comfort. The device of a plasterboard ceiling largely depends on its configuration and the desired method of lighting. In any case, metal profiles of various purposes, plasterboard sheets (GKL) and additional components in the form of hangers, fasteners, lamps, etc. are used for installation. The difference is that the arrangement of a single-level ceiling is carried out in one, horizontal plane, and to create multi-level ceilings, the sheets are fastened in horizontal and vertical planes. Naturally, at the design stage it is necessary to provide for the convenience of laying lighting wires, the type and size of the lamps, the desired direction of light flows, methods of connecting and adjusting the lighting. Return to contents</a>

Sketch of a plasterboard ceiling.You can make a ceiling with your own hands in any room, with the exception of perhaps the bathroom (high humidity in the room will not have a very good effect on this material). Even small rooms with low ceilings can be transformed thanks to the original design. However, it is necessary to take into account that due to the installation of plasterboard ceilings, the height will be noticeably reduced. In this case, will come to the rescue, in the niches of which it is possible to place lighting and thereby reduce to nothing some of the disadvantages, increase the volume and provide comfort. The device of a plasterboard ceiling largely depends on its configuration and the desired method of lighting. In any case, metal profiles of various purposes, plasterboard sheets (GKL) and additional components in the form of hangers, fasteners, lamps, etc. are used for installation. The difference is that the arrangement of a single-level ceiling is carried out in one, horizontal plane, and to create multi-level ceilings, the sheets are fastened in horizontal and vertical planes. Naturally, at the design stage it is necessary to provide for the convenience of laying lighting wires, the type and size of the lamps, the desired direction of light flows, methods of connecting and adjusting the lighting. Return to contents</a>

How to get started

Scheme of a multi-level plasterboard ceiling.The first step towards implementing the plan will be a sketch of the future ceiling. This stage is especially important, especially if the design includes curved lines, round or semicircular elements. The sketch can be sketched on a regular sheet of paper, but it is very important to maintain the scale so that you can accurately calculate the dimensions at all nodal points, as well as take into account the layout of the room, including window openings, doors, and furniture arrangement. The next important step is transferring the drawing to the ceiling. Here it is very important to maintain the accuracy of the dimensions and lines. When drawing wavy and round elements, it is advisable to use a compass. But first, the ceiling is installed at one level, the future basis for attaching additional structural elements. Actually, the ceiling design itself will not require any special skills and devices, except, perhaps, a tape measure and a pencil. And to perform subsequent work on arranging the ceiling with your own hands, you will need tools and devices:

Scheme of a multi-level plasterboard ceiling.The first step towards implementing the plan will be a sketch of the future ceiling. This stage is especially important, especially if the design includes curved lines, round or semicircular elements. The sketch can be sketched on a regular sheet of paper, but it is very important to maintain the scale so that you can accurately calculate the dimensions at all nodal points, as well as take into account the layout of the room, including window openings, doors, and furniture arrangement. The next important step is transferring the drawing to the ceiling. Here it is very important to maintain the accuracy of the dimensions and lines. When drawing wavy and round elements, it is advisable to use a compass. But first, the ceiling is installed at one level, the future basis for attaching additional structural elements. Actually, the ceiling design itself will not require any special skills and devices, except, perhaps, a tape measure and a pencil. And to perform subsequent work on arranging the ceiling with your own hands, you will need tools and devices: Tools for installing plasterboard on the ceiling.

Tools for installing plasterboard on the ceiling.

- level (preferably water);

- perforator;

- screwdriver or drill (better both, and more);

- gon (for right angles);

- a Bulgarian or scissors for cutting metal;

- cord and hacksaw for working with plasterboard;

- roller on a long handle with a needle surface (for curved sections).

The basic materials you will need are:

- drywall itself;

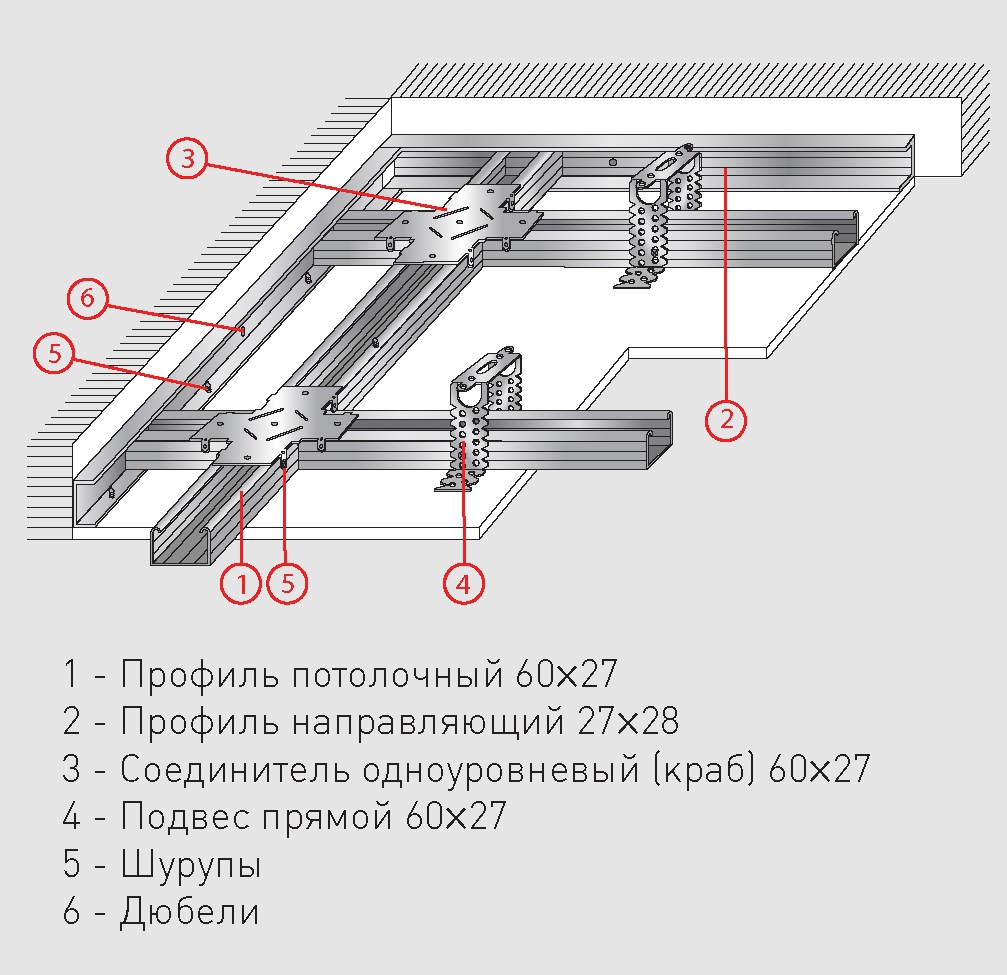

- bearing and transverse profiles, "crabs";

- dowels 6 * 60 mm and the corresponding drills;

- 4 cm self-tapping screws and hangers;

- elements of illumination (a light-emitting diode tape, fixtures, wires, fastenings).

Return to Contents</a>

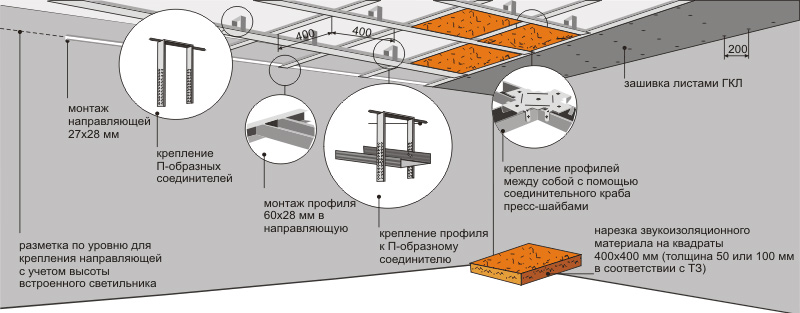

Installation of a skeleton of a ceiling

First you need to determine where it will come fromstart the first level of the ceiling. Then mark the places for attaching the hangers, taking into account the profile pitch (40 cm) and the hanger pitch - 60-65 cm. The orientation of the profile is determined based on the configuration of the pattern and the dimensions of the room. It is not necessary to place the profile perpendicular to the windows just to make the seams less noticeable. It is better to take into account the length of the profile, the need for its extension, the location of the gypsum board, the bundle of sheets. Scheme of the plasterboard ceiling frame.The supporting profile is fixed with dowels and screws in 0.5 meter increments. A cross profile is inserted into the structure fixed to the wall, and the length of its sections should be slightly less than the distance between the walls. Before assembling the ceiling, the cross profile must be aligned. For this purpose, a cord is usually pulled through, which serves as a guide during installation. For more reliable fastening of the gypsum board, a U-shaped profile is used, which is fixed to the ceiling in 0.9 m increments. Sheeting begins from the far corner of the room. The sheets are attached to the cross profile with self-tapping screws. If the width of the room is larger than the size of the sheet, the sheets are fixed in a checkerboard pattern: first, whole sheets are fixed, then individual sections, cutting the gypsum board to size. The single-level ceiling is ready. Return to contents</a>

Scheme of the plasterboard ceiling frame.The supporting profile is fixed with dowels and screws in 0.5 meter increments. A cross profile is inserted into the structure fixed to the wall, and the length of its sections should be slightly less than the distance between the walls. Before assembling the ceiling, the cross profile must be aligned. For this purpose, a cord is usually pulled through, which serves as a guide during installation. For more reliable fastening of the gypsum board, a U-shaped profile is used, which is fixed to the ceiling in 0.9 m increments. Sheeting begins from the far corner of the room. The sheets are attached to the cross profile with self-tapping screws. If the width of the room is larger than the size of the sheet, the sheets are fixed in a checkerboard pattern: first, whole sheets are fixed, then individual sections, cutting the gypsum board to size. The single-level ceiling is ready. Return to contents</a>

How to fix curvilinear structures

After installing the single-level structureceiling, you can start transferring the sketch in accordance with the chosen ceiling design. In this case, you need to transfer the entire image at once. To display circles or curved lines, you can use improvised means in the form of a pencil and a thin cord. At the point corresponding to the puncture of the compass on the paper, screw in a screw, to which the cord is attached. Then measure the required size of the circle, tie a loop at the other end, simply thread the pencil through it and draw the required segment. To transfer smooth lines, you need to measure the inflection points, and then, using a long, narrow, well-bending object, draw the required line. Installation of plasterboard ceiling.When making a ceiling with your own hands, you need to take into account that for reliable fastening of the second level to the frame of the first, a perforated main profile is used, which is attached to the guides using self-tapping screws, necessarily in the profile, and not in the plasterboard. If there is no perforated profile, you can make it yourself: cut the side walls of a regular profile every 50 mm. To install the elements of the second level of the ceiling with your own hands, the new frame can be attached either directly to the existing ceiling or rest on wall guides, for which a guide profile is fixed to the wall, having retreated a distance equal to the height of the second level. The main profile will be fixed on the wall profile on one side, and on the other - fixed with U-shaped hangers. If necessary, such hangers are installed every 50 cm. After assembling the frame, all surfaces are sheathed with plasterboard. When cutting out the desired area, it is necessary to leave allowances of 5-6 cm. After installation, the excess is cut off with a knife or a jigsaw. To fix a curved plasterboard strip, the material must first be moistened and rolled with a needle roller (several times if necessary). After some time, the strip can be freely given the desired shape and attached to the profile with screws. When screwing in the screws, you need to ensure that the cap is completely recessed. Having completed the installation of the main structures, you can begin finishing work - installing lighting fixtures, puttying, grinding, priming and, at the final stage, painting or wallpapering.</ ul>

Installation of plasterboard ceiling.When making a ceiling with your own hands, you need to take into account that for reliable fastening of the second level to the frame of the first, a perforated main profile is used, which is attached to the guides using self-tapping screws, necessarily in the profile, and not in the plasterboard. If there is no perforated profile, you can make it yourself: cut the side walls of a regular profile every 50 mm. To install the elements of the second level of the ceiling with your own hands, the new frame can be attached either directly to the existing ceiling or rest on wall guides, for which a guide profile is fixed to the wall, having retreated a distance equal to the height of the second level. The main profile will be fixed on the wall profile on one side, and on the other - fixed with U-shaped hangers. If necessary, such hangers are installed every 50 cm. After assembling the frame, all surfaces are sheathed with plasterboard. When cutting out the desired area, it is necessary to leave allowances of 5-6 cm. After installation, the excess is cut off with a knife or a jigsaw. To fix a curved plasterboard strip, the material must first be moistened and rolled with a needle roller (several times if necessary). After some time, the strip can be freely given the desired shape and attached to the profile with screws. When screwing in the screws, you need to ensure that the cap is completely recessed. Having completed the installation of the main structures, you can begin finishing work - installing lighting fixtures, puttying, grinding, priming and, at the final stage, painting or wallpapering.</ ul>