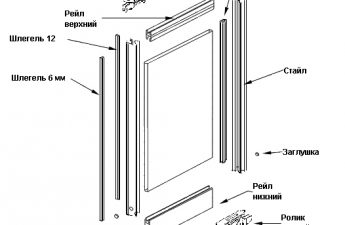

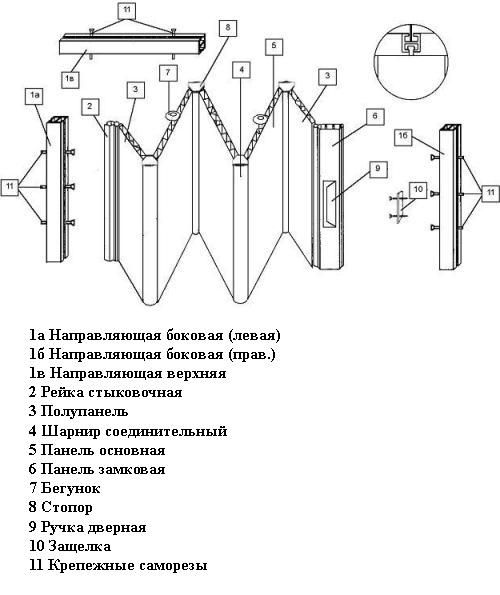

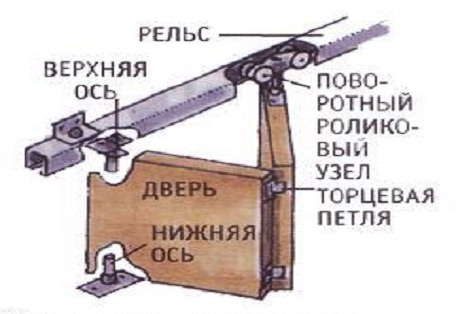

Not everyone can boast of havingapartments with a large area and a convenient layout. In this case, the accordion door, manufactured and installed by its own hands, will help not only to rationalize the already scarce internal space, but also to save the family budget considerably.  Diagram of a folding door-accordion.

Diagram of a folding door-accordion.

Distinctive features of the accordion door

Like any functional object, the accordion door has its pros and cons, which determine the scope of its use. Its indisputable advantages include:  Tools for mounting the door-accordion.

Tools for mounting the door-accordion.

- saving space;

- the versatility of the design, allowing the left- or right-hand opening scheme (depending on which side of the joint is to be installed);

- the design of the door, which does not allow spontaneous opening or closing under the influence of drafts or incorrect installation of loops;

- high decorative and aesthetic qualities, allowing to fit into almost any interior;

- the possibility of automation and control of the process of opening and closing with the help of the remote control.

The main drawback is related to the principle of work. In the design of the sliding door, there are many moving parts. It is also known from the course of school physics that a body interacting with other bodies through frictional forces will be subject to greater wear than the one at rest. In other words, the service life of such doors is relatively short: about five, a maximum of ten years. Another feature of sliding doors, limiting their use, is their low mechanical strength. Using a smaller number of door segments and additional rails, it is possible to increase the structural strength, but still it will be considerably inferior to the sliding panel or panel doors. Back to contents</a>

Components of the structure

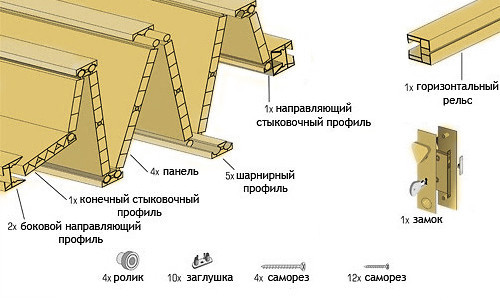

The accordion door includes the following elements:  The order of assembling the folding door.

The order of assembling the folding door.

If necessary, the entire structure canadditionally equipped with devices such as seals. They create a sealing circuit around the perimeter of the sliding door and protect the room from drafts. Another useful additional device is a stopper, which allows you to lock the door in an open or semi-open position. Back to contents</a>

Materials for the manufacture of doors

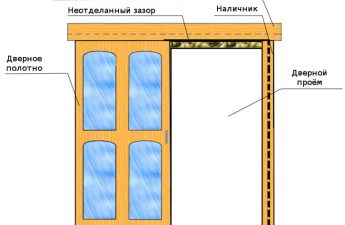

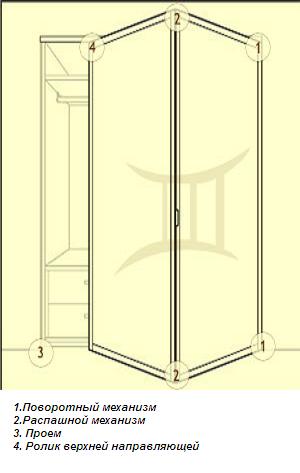

Diagram of a folding door of two elements. In order to independently manufacture the sliding door accordion, you need to use any sheet material. It can be:

Diagram of a folding door of two elements. In order to independently manufacture the sliding door accordion, you need to use any sheet material. It can be:

- an array of wood (panels, furniture boards);

- dsp;

- mdf;

- sheet materials on the basis of plastic;

- frame structures (frame-frame made of wooden slats with plywood or dvp fixed on it).

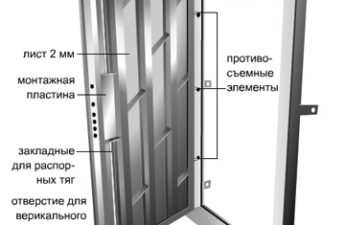

More exotic materials can be mentionedfabric, leather and tempered glass. In self-manufacturing, it is easiest to use materials from solid wood or frame structures. Compared with all other options, the tree has an optimal ratio of strength, weight and ease of processing. The time variation of geometric parameters of a tree array can be compensated for using a previously dried material or a framework structure.  The scheme of the mechanism of the folding door. Modern finishing paint and varnish materials can give almost any kind of door leaf. In addition, if desired, wooden lamellas can easily be repainted in a different color or refreshed the existing coating. In the process of manufacturing and installation of a sliding door, a number of widely used tools are needed, which are in the arsenal of almost every home master:

The scheme of the mechanism of the folding door. Modern finishing paint and varnish materials can give almost any kind of door leaf. In addition, if desired, wooden lamellas can easily be repainted in a different color or refreshed the existing coating. In the process of manufacturing and installation of a sliding door, a number of widely used tools are needed, which are in the arsenal of almost every home master:

- electric drill;

- Screwdriver;

- electric jig saw;

- Hacksaw for metal (for cutting rails);

- level.

Consumables that may be needed during installation:

- self-tapping screws;

- loops;

- set of rollers.

Having everything you need at hand you can start making a sliding door. Back to contents</a>

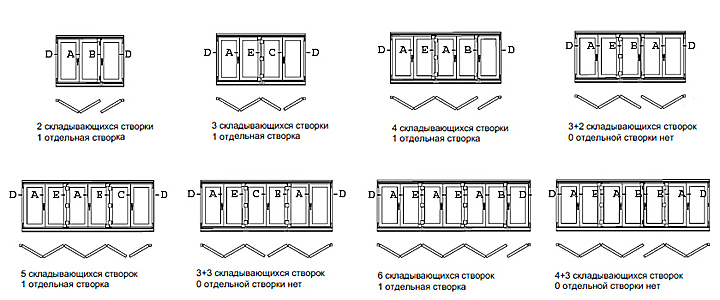

Cutting of door leaf parts

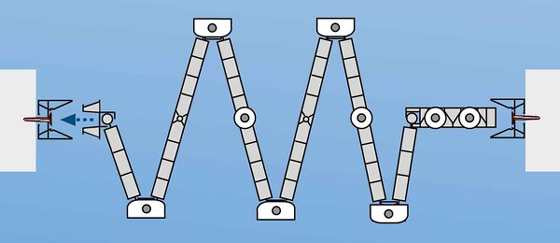

Varieties of folding doors. When you make the door slats yourself, remember that the smaller the width, the less space will be freed up due to the more compact dimensions of the door when folded. However, a thoughtless reduction in width will lead to an unjustified increase in the number of moving parts, which will drastically reduce the reliability of the structure as a whole. Here it is necessary to seek a compromise between dimensions and strength characteristics. It is believed that the sliding doors should have a width of individual segments of 10-15, a maximum of 20 cm. An exception can be considered a kind of folding door - a door-book. It has only two lamellas in the composition of the door leaf. The selected material is cut into individual strips of the desired length and width. Dimensions and number of strips are determined by the dimensions of the doorway. The lamella, into which the lock will be installed, should be somewhat smaller in width (5-10 cm). This is due to the fact that it will remain unformed in the opening and partially cover its free passage. The very first lamella that joins the joint can differ in size from all the others.

Varieties of folding doors. When you make the door slats yourself, remember that the smaller the width, the less space will be freed up due to the more compact dimensions of the door when folded. However, a thoughtless reduction in width will lead to an unjustified increase in the number of moving parts, which will drastically reduce the reliability of the structure as a whole. Here it is necessary to seek a compromise between dimensions and strength characteristics. It is believed that the sliding doors should have a width of individual segments of 10-15, a maximum of 20 cm. An exception can be considered a kind of folding door - a door-book. It has only two lamellas in the composition of the door leaf. The selected material is cut into individual strips of the desired length and width. Dimensions and number of strips are determined by the dimensions of the doorway. The lamella, into which the lock will be installed, should be somewhat smaller in width (5-10 cm). This is due to the fact that it will remain unformed in the opening and partially cover its free passage. The very first lamella that joins the joint can differ in size from all the others.  The scheme of installation of the roller mechanism. If the width of all segments is the same, the sliding door in the assembled form will extend beyond the doorway, which is undesirable. For the most compact placement, the first segment of the door leaf should be twice as large as all others. Then the door in the folded position will be exactly in the middle with respect to the thickness of the jamb. After cutting, the individual edges of the obtained parts are carefully processed by sandpaper to remove the slightest burrs, which inevitably appear when sawing. Back to contents</a>

The scheme of installation of the roller mechanism. If the width of all segments is the same, the sliding door in the assembled form will extend beyond the doorway, which is undesirable. For the most compact placement, the first segment of the door leaf should be twice as large as all others. Then the door in the folded position will be exactly in the middle with respect to the thickness of the jamb. After cutting, the individual edges of the obtained parts are carefully processed by sandpaper to remove the slightest burrs, which inevitably appear when sawing. Back to contents</a>

Assembling the door leaf

The door leaf is assembled by connecting the lamellas with each other using hinges. Hinges can be used in a variety of designs:  Scheme of the roller mechanism of the door frame.

Scheme of the roller mechanism of the door frame.

- guide-hinges;

- end hinges;

- piano loops.

Even ordinary furniture loops can be used. If you make an accordion yourself, it's better to install piano loops on the door. They are quite simple to install, add extra spatial rigidity to the structure and, importantly, they are easy to get, and they are cheap. The only nuance that can not be overlooked during installation is the orientation of the loops. On the opposite edges of the lamellas, the hinges must be fixed from opposite sides. This will provide the required transformation mechanism. Otherwise, nothing will happen. Then it is necessary to install the rollers in the upper and, if necessary, in the lower ends of the door segments. Rollers are fixed in the middle of the length of the butt through one lamella. Back to contents</a>

Sliding door installation: recommendations

After the sliding door is assembled, it must be assembled in its place. The installation of the door is quite simple:

After final fixing and adjustmentWe can assume that the main work is done. It remains only to periodically inspect the mobile connections and, if necessary, lightly lubricate them and tighten the fasteners of the hinges.