Wood as a natural material was usedpopular at all times. Its valuable properties as a natural raw material have been appreciated by many generations. Natural wood is still actively used in construction: it is used to make strong, safe and beautiful doors. Constructions made for outbuildings, residential buildings are made according to the same scheme, they will differ only in the features of the cladding, the originality of the fittings and reinforcing details. They also differ in style and place of installation. Do-it-yourself wooden doors are unique, interesting and original. To make them correctly, you should strictly follow the main stages of installation. Solid wood doors are highly durable and insulate the room well from noise. Wooden structures are manufactured in the following versions:

Solid wood doors are highly durable and insulate the room well from noise. Wooden structures are manufactured in the following versions:

- paneled;

- shield;

- the deaf from the array;

- with stained glass.

Entrance and interior options are presentedcanvases with a blind coating or with additional elements made of tempered glass elements. These details perform a decorative role. Panel doors are used as interior samples. The top layer of wood is most often treated with varnish or veneer.

Preliminary preparation for work

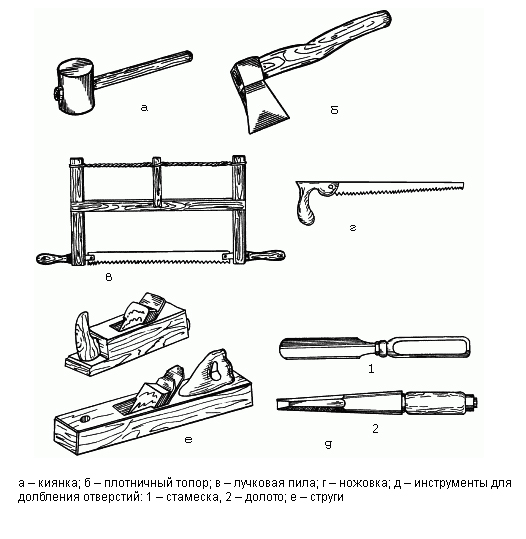

You can make a solid wood door yourself by preparing a number of necessary tools: Types of wood for making doors.

Types of wood for making doors.

- plane;

- hacksaw;

- a hammer;

- chisel;

- roulette;

- self-tapping screws;

- glue joiner;

- sandpaper;

- screwdriver or screwdriver;

- Grinder.

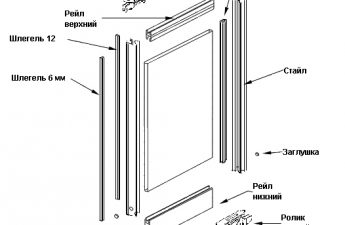

Care should be taken to select qualitywood. Pine, spruce, larch, oak, and ash are best suited for these purposes. However, when choosing hardwood, it is worth considering that their processing at home may be difficult. Softwoods are most suitable for self-production. The used array must be well-dried, smooth, and large knots and cracks are not allowed. In order for natural raw materials to acquire the required moisture content, they are laid out outside in sunny and dry weather for 14 days. Scheme for making a wooden door.The number of planks used is determined by the type of door leaf. Thus, a panel door requires a minimum amount of material, while a blind type needs to increase it. Next, the opening is measured. 8 mm are added to the obtained figures if a threshold is required. After this, you can make a box on which the door is fixed. The opening consists of two vertical planks and the same number of crossbars. Their plane is created for the placement of fastening tenons on it. Openings with tenon and groove fastening are made with a hacksaw and a knife. Then they are fixed with glue. The door leaf should be 3 mm smaller in size than the dimensions of the box. This way, the structure will close and open freely. A solid sheet of natural coating or fiberboard is taken for doors. It is advisable to carry out the manufacturing process of the structure on a flat horizontal surface. First, the dimensions of the future products are compared. To make a box, a bar is used, the thickness of which is 5 cm, and the width is 10 cm. 10 cm. Return to contents</a>

Scheme for making a wooden door.The number of planks used is determined by the type of door leaf. Thus, a panel door requires a minimum amount of material, while a blind type needs to increase it. Next, the opening is measured. 8 mm are added to the obtained figures if a threshold is required. After this, you can make a box on which the door is fixed. The opening consists of two vertical planks and the same number of crossbars. Their plane is created for the placement of fastening tenons on it. Openings with tenon and groove fastening are made with a hacksaw and a knife. Then they are fixed with glue. The door leaf should be 3 mm smaller in size than the dimensions of the box. This way, the structure will close and open freely. A solid sheet of natural coating or fiberboard is taken for doors. It is advisable to carry out the manufacturing process of the structure on a flat horizontal surface. First, the dimensions of the future products are compared. To make a box, a bar is used, the thickness of which is 5 cm, and the width is 10 cm. 10 cm. Return to contents</a>

Making a box: recommendations

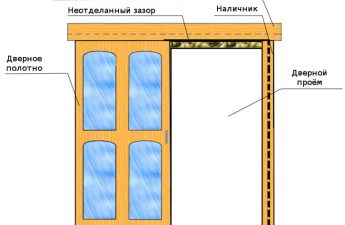

Door drawing.This important part is fixed to the doorway, it serves as a starting point for fastening the canvas. To give this element maximum strength, it is made of wood. It looks like two vertical posts and the same number of crossbars. On their surface, the connection points and the locations of the connecting grooves are marked. Using a hacksaw and a knife, openings are made similar to a tenon-and-groove connection. After that, they are lubricated with an adhesive substance and tightly connected. The finished canvas is inserted into the specified space and fixed at the base of the wall with self-tapping screws. Return to the table of contents</a>

Door drawing.This important part is fixed to the doorway, it serves as a starting point for fastening the canvas. To give this element maximum strength, it is made of wood. It looks like two vertical posts and the same number of crossbars. On their surface, the connection points and the locations of the connecting grooves are marked. Using a hacksaw and a knife, openings are made similar to a tenon-and-groove connection. After that, they are lubricated with an adhesive substance and tightly connected. The finished canvas is inserted into the specified space and fixed at the base of the wall with self-tapping screws. Return to the table of contents</a>

Manufacture of door leaf

If the structure is made from solid wood, buyit can be purchased at a building supply store, since the necessary equipment for its production will not be available in a residential setting. It is made by gluing together timber and planks. It is most convenient to carry out such activities on the floor: Tools for making a wooden door.

Tools for making a wooden door.

- the prepared material is laid out on a flat plane, here also small and lumber-sized vertical and horizontal types are placed;

- The points of connection of boards are marked with a pencil, the angle of joining should correspond to 90 °;

- The longest parts serve to heal studs on their surface, in work should be especially careful and careful, the joining of parts must be necessarily smooth;

- a groove is made in the end part of small boardshole, from the inside - a tenon, the number of such elements can be one or two, it is most convenient for a non-professional to work with a simple tenon corresponding to half the thickness of the wood;

- spike and groove joints are coated with an adhesive, followed by fastening them to parts of the fiberboard taken in the number of two pieces, resulting in a multi-layered construction;

- the available parts are connected by screws 25 mm;

- if necessary, the door should be dried for 3 days, previously it is put on the load, as the drying out the outer layer is treated with a grinding machine.

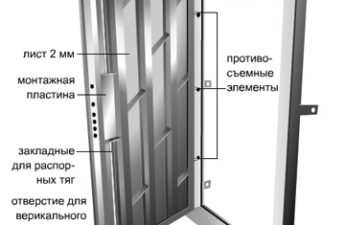

You can make entrance doors using the same scheme.The only difference is in the insulation of the device. For such purposes, thin mineral wool plates are used. More reliable protection can be obtained by placing an iron plate inside such a device, the thickness of which is 2 mm. This is how armored wooden structures are made. After this, hinges and locks are attached to the canvas. Return to the table of contents</a>

Warming of the door: features

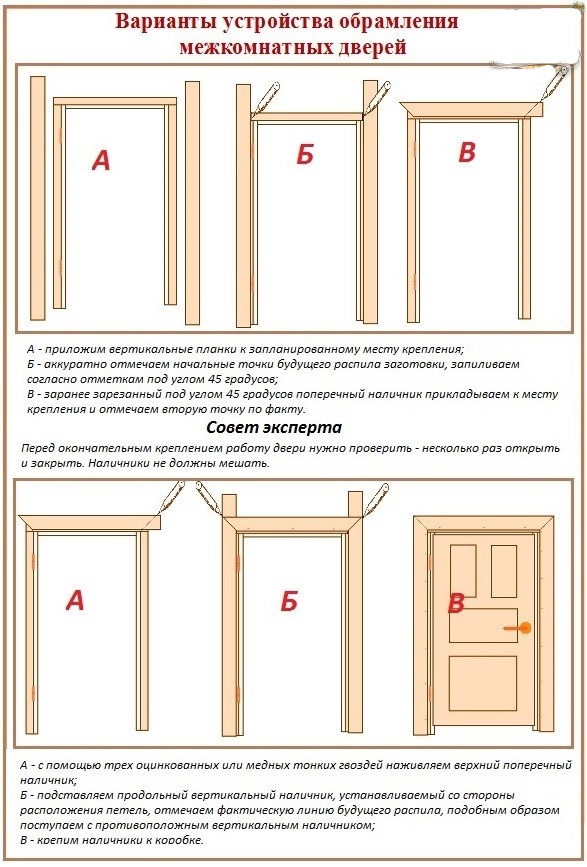

If desired, the solid wood panel can be insulated.For this purpose, the structure is designed from the inside and outside. From the inside of the door, empty spaces are filled with any porous material. This can be glass wool, foam, polystyrene, or mounting foam. Internal insulation can be done using the following components: Installation of door frames for interior doors.

Installation of door frames for interior doors.

- piece of foam rubber, the thickness of which corresponds to 1.5-2 cm;

- artificial leather length of 25-30 cm;

- glue;

- large scissors;

- Furniture stapler;

- special nails.

It is best to cover such a door with an assistant.The foam rubber is cut with a small margin, 8-10 cm more, then it should be glued to the canvas. The outer part is decorated with artificial leather, while it is important to ensure the same amount of material on all sides. The size of such a canvas corresponds to the dimensions of the door, from which 1 cm is subtracted. Here you will need an assistant who helps to stretch the material onto the surface of the structure. A furniture stapler is used for fastening. It is important to ensure that the fabric is tightly stretched; there should be no wrinkles or folds on it. The cut parts of the leatherette are stretched and fastened with staples along the edge of the canvas: first, they are simply fixed to the surface, then folded and nailed with furniture nails. The connection points of the vertical and horizontal strips are tucked at an angle of 45 ° and fixed with nails. Recommendation: to make the slot for the door handle look more attractive, a hole is made at the back of the door, then a cross-shaped slot is made with a sharp blade, which must be pierced in the center. Return to Contents</a>

Quick way to paint wooden doors

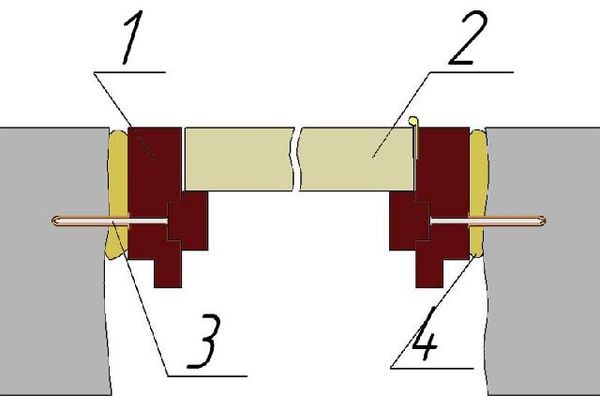

Scheme of fastening the door frame in the opening:1 – frame, 2 – interior door, 3 – screws, 4 – foam. The finished wooden door requires further external finishing. For this, the surface is often covered with paint, using the fastest painting methods. These are spray cans, spray guns, rollers and brushes. Before applying paint, you should study the information on the can: it must be intended for wooden surfaces. So, with the help of a spray gun, you can achieve ideal results: the coating will be even and smooth, without drips and streaks. The best paint option will be a substance of liquid consistency, otherwise a solvent is used, the diluted paint is filtered through a sieve: such measures will prevent clogging of the device nozzle. It is not necessary to cover the door with primers, usually the wooden coating is already even and smooth. Return to the table of contents</a>

Scheme of fastening the door frame in the opening:1 – frame, 2 – interior door, 3 – screws, 4 – foam. The finished wooden door requires further external finishing. For this, the surface is often covered with paint, using the fastest painting methods. These are spray cans, spray guns, rollers and brushes. Before applying paint, you should study the information on the can: it must be intended for wooden surfaces. So, with the help of a spray gun, you can achieve ideal results: the coating will be even and smooth, without drips and streaks. The best paint option will be a substance of liquid consistency, otherwise a solvent is used, the diluted paint is filtered through a sieve: such measures will prevent clogging of the device nozzle. It is not necessary to cover the door with primers, usually the wooden coating is already even and smooth. Return to the table of contents</a>

Installing the door in the opening

The door manufacturing process is completed by itsinstallation. To do this, simply hang the door leaf on the hinges of the finished frame. Recommendation: it is most convenient to do such actions with an assistant. If the door frame is missing, holes are drilled according to the specified dimensions and installation is carried out using dowels. The trims are fastened with thin screws. Finally, the door is hung. So, the presented tips, recommendations, as well as a detailed manufacturing diagram will allow you to make a door with your own hands. In the process of carrying out such work, you can not only learn a new craft, but also save a lot of money.</ ul>