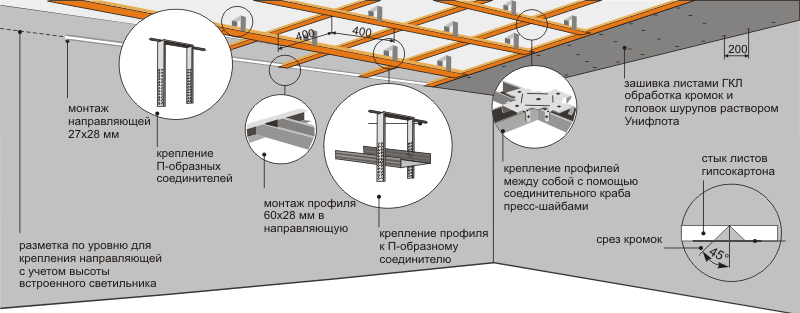

During renovations in an apartment or houseQuite a few difficulties have to be experienced in order to bring the ceiling into full order. Here you can encounter uneven laying of slabs, with mismatched angles, with incorrectly mounted ceiling. Installation diagram for a suspended plasterboard ceiling.It is quite difficult to eliminate all the problems. But there are many ways and materials to solve this problem. The most common of them are the installation of stretch ceilings and the installation of suspended structures made of plasterboard (GKL) with your own hands. A stretch ceiling is good, but it is worth considering in more detail the methods of implementation.

Installation diagram for a suspended plasterboard ceiling.It is quite difficult to eliminate all the problems. But there are many ways and materials to solve this problem. The most common of them are the installation of stretch ceilings and the installation of suspended structures made of plasterboard (GKL) with your own hands. A stretch ceiling is good, but it is worth considering in more detail the methods of implementation.

Advantages of gypsum board ceiling

Installation of a suspended ceiling made of plasterboard has a number of undeniable advantages over other methods: Fastening plasterboard.

Fastening plasterboard.

- relatively low cost of the finished structure;

- simplicity of installation of structures;

- quick installation;

- the ability to perform all the work independently;

- hiding the shortcomings of the main ceiling;

- possibility to hide wires and pipes;

- completely flat surface;

- excellent soundproofing properties.

Return to Contents</a>

Tools for work

To perform work on installing a suspended ceiling, you need to prepare the following tools:

- water level;

- building level 2 m long;

- perforator;

- Screwdriver;

- roulette, pencil, building knife;

- scissors for cutting metal.

Installation diagram for a single-level suspended ceiling.A water level is needed to mark the places where a special profile will be installed. The level consists of a long plastic hose with glass flasks with divisions installed at the ends. The flasks have unique handles. Before work, the hose is filled with water, which can be tinted for convenience. It is essential to work with such a level in pairs. If finances allow, you can buy a laser level. This is a more convenient and accurate device. A two-meter level will be needed in the process of determining the horizontality during the installation of gypsum board. Holes are drilled in the walls and ceiling with a hammer drill. They are necessary for fastening the guides with dowels and self-tapping screws, which will be screwed in with a screwdriver. The gypsum board sheets are also screwed to the guides with a screwdriver. All measurements and marks are set according to a tape measure with an ordinary pencil and a knife. A knife is also needed for cutting the drywall. Scissors are used to cut the metal guides to the required size. Return to the table of contents</a>

Installation diagram for a single-level suspended ceiling.A water level is needed to mark the places where a special profile will be installed. The level consists of a long plastic hose with glass flasks with divisions installed at the ends. The flasks have unique handles. Before work, the hose is filled with water, which can be tinted for convenience. It is essential to work with such a level in pairs. If finances allow, you can buy a laser level. This is a more convenient and accurate device. A two-meter level will be needed in the process of determining the horizontality during the installation of gypsum board. Holes are drilled in the walls and ceiling with a hammer drill. They are necessary for fastening the guides with dowels and self-tapping screws, which will be screwed in with a screwdriver. The gypsum board sheets are also screwed to the guides with a screwdriver. All measurements and marks are set according to a tape measure with an ordinary pencil and a knife. A knife is also needed for cutting the drywall. Scissors are used to cut the metal guides to the required size. Return to the table of contents</a>

Materials for work

Installation of suspended plasterboard ceilings is impossible without materials such as:

- metallic profile;

- drywall;

- hangers straight;

- dowels for fastening;

- gypsum plaster or putty;

- ribbon-serpyanka;

- abrasive sandpaper.

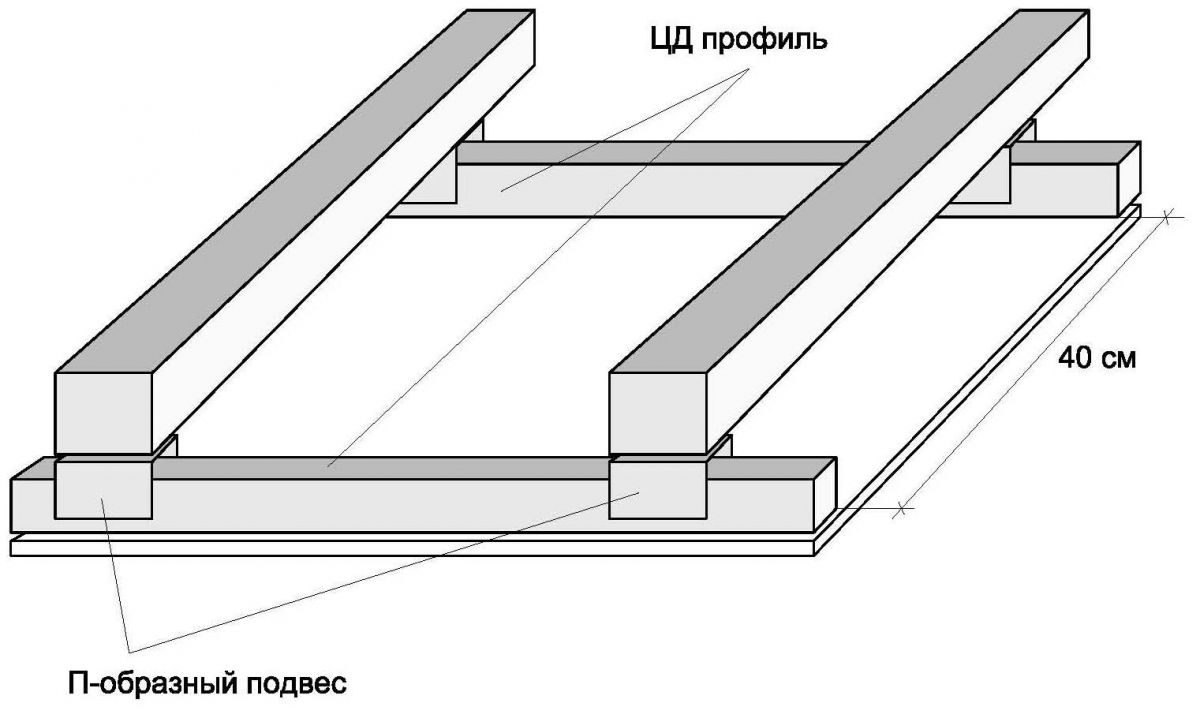

The profiles sold in stores vary.The ceiling requires a guide and a ceiling one. The guide (PN) has dimensions of 28x27 mm. It is attached to the upper parts of the wall along the perimeter of the ceiling. The ceiling (PP) has a C-shape with dimensions of 60x27 mm and is attached directly to the ceiling surface. Scheme of a two-level suspended ceiling fromplasterboard. To build a ceiling, you need to buy both profiles from the same manufacturer. The quantity depends on the perimeter of the room. As an example, we can take a room with wall sizes of 4 and 5 m. The profile goes on sale in sizes of 3 and 4 m. It follows that you need to buy at least 7 pieces of three-meter material. You will need 5 pieces of four-meter material. Some apartment owners build multi-level ceilings of intricate shapes. In this case, the material consumption will increase. If the ceiling elements are installed with a step of 60 cm, then you will need 8 profiles 4 m long. The amount of material for rooms of other sizes is calculated similarly. Plasterboard is produced in sheets in different versions: regular, moisture-resistant and fireproof. For living rooms, a regular sheet with a thickness of 8-10 mm is more suitable. The area of the sheet is approximately 3 sq. m. The total amount is quite easy to calculate. It is recommended to purchase guides and plasterboard with a small reserve in case of unintentional damage to the material. All parts are fastened using hangers. You need about 40-50 straight hangers per room, more for complex configurations. To fasten them, you need to stock up on dowels and screws. Screws for fastening drywall should be about 25 mm long, for fastening hangers - depending on the quality and material of the ceiling and walls. Return to contents</a>

Scheme of a two-level suspended ceiling fromplasterboard. To build a ceiling, you need to buy both profiles from the same manufacturer. The quantity depends on the perimeter of the room. As an example, we can take a room with wall sizes of 4 and 5 m. The profile goes on sale in sizes of 3 and 4 m. It follows that you need to buy at least 7 pieces of three-meter material. You will need 5 pieces of four-meter material. Some apartment owners build multi-level ceilings of intricate shapes. In this case, the material consumption will increase. If the ceiling elements are installed with a step of 60 cm, then you will need 8 profiles 4 m long. The amount of material for rooms of other sizes is calculated similarly. Plasterboard is produced in sheets in different versions: regular, moisture-resistant and fireproof. For living rooms, a regular sheet with a thickness of 8-10 mm is more suitable. The area of the sheet is approximately 3 sq. m. The total amount is quite easy to calculate. It is recommended to purchase guides and plasterboard with a small reserve in case of unintentional damage to the material. All parts are fastened using hangers. You need about 40-50 straight hangers per room, more for complex configurations. To fasten them, you need to stock up on dowels and screws. Screws for fastening drywall should be about 25 mm long, for fastening hangers - depending on the quality and material of the ceiling and walls. Return to contents</a>

Mounting of the skeleton of the ceiling

Installation is carried out in the following order:

Scheme of correct use of water levelfor marking a suspended ceiling. First, you need to mark the walls for attaching the guides to them. This is where a water or laser level will come in handy. It is recommended to step back about 10 cm from the old ceiling. Water is poured into the level tube. Glass vessels are placed on opposite walls and marks are made. After marking all the walls, the marked points can be connected and an even horizontal line is obtained. Holes for dowels are drilled along it every 30-40 cm. Every 60 cm, marks are made on the wall along which the ceiling profiles will be installed. On a simple ceiling, they are installed parallel to each other, so only 2 opposite walls need to be marked. Straight hangers and longitudinal profiles are installed. The ends of the profiles are tucked into the grooves of the guides and are attached to the ceiling surface with straight hangers. It is necessary to take into account the following moment: the ceiling profile in the grooves of the supporting elements should not reach the wall by approximately 0.5-1.0 cm. At the intersections of the profiles, they are fastened with self-tapping screws. The finished frame is checked for horizontality with a long level. Return to the table of contents</a>

Scheme of correct use of water levelfor marking a suspended ceiling. First, you need to mark the walls for attaching the guides to them. This is where a water or laser level will come in handy. It is recommended to step back about 10 cm from the old ceiling. Water is poured into the level tube. Glass vessels are placed on opposite walls and marks are made. After marking all the walls, the marked points can be connected and an even horizontal line is obtained. Holes for dowels are drilled along it every 30-40 cm. Every 60 cm, marks are made on the wall along which the ceiling profiles will be installed. On a simple ceiling, they are installed parallel to each other, so only 2 opposite walls need to be marked. Straight hangers and longitudinal profiles are installed. The ends of the profiles are tucked into the grooves of the guides and are attached to the ceiling surface with straight hangers. It is necessary to take into account the following moment: the ceiling profile in the grooves of the supporting elements should not reach the wall by approximately 0.5-1.0 cm. At the intersections of the profiles, they are fastened with self-tapping screws. The finished frame is checked for horizontality with a long level. Return to the table of contents</a>

Mounting plasterboard to the frame

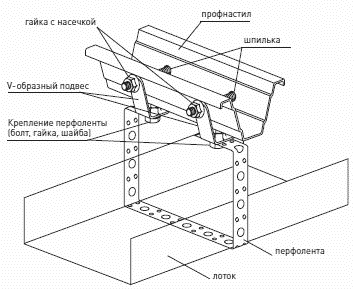

After installing the frame, they stretchelectrical wiring, if necessary, a heat insulator is placed between the profile elements. It is time to attach the plasterboard sheets. There are no difficulties here. Only additional labor is needed to lift the sheets. They are pressed against the frame and screwed with self-tapping screws every 10-15 cm. It is advisable to sink the screw heads into the plasterboard to a depth of about 0.5-1.0 mm. Diagram of the device for fastening corrugated sheets.These recesses will be filled later. The necessary holes for chandeliers and other lamps in the sheets are cut with a sharp knife or a special attachment installed in a drill or hammer drill. The finished ceiling is filled. The seams between the sheets of drywall can be glued with a special reinforcing mesh. After a day, you can repeat the filler process. After a couple of days, the entire surface is treated with sandpaper. Now the ceiling is ready for any kind of decorative finishing. It can be painted, wallpapered, decorative plaster applied, or backlighting installed. The finished ceiling may look something like this. You can build new suspended ceilings in your home during renovations from drywall. This is an excellent material with a number of advantages. For the work, you will need some more components, without which it is impossible to work with gypsum board. These are guides, screws, dowels, putty. All the work can be done with your own hands and save a significant amount of money on this. After constructing a simple single-level ceiling, you will definitely have a moment when you want to create something more beautiful. Try it, everything will work out!</ ul>

Diagram of the device for fastening corrugated sheets.These recesses will be filled later. The necessary holes for chandeliers and other lamps in the sheets are cut with a sharp knife or a special attachment installed in a drill or hammer drill. The finished ceiling is filled. The seams between the sheets of drywall can be glued with a special reinforcing mesh. After a day, you can repeat the filler process. After a couple of days, the entire surface is treated with sandpaper. Now the ceiling is ready for any kind of decorative finishing. It can be painted, wallpapered, decorative plaster applied, or backlighting installed. The finished ceiling may look something like this. You can build new suspended ceilings in your home during renovations from drywall. This is an excellent material with a number of advantages. For the work, you will need some more components, without which it is impossible to work with gypsum board. These are guides, screws, dowels, putty. All the work can be done with your own hands and save a significant amount of money on this. After constructing a simple single-level ceiling, you will definitely have a moment when you want to create something more beautiful. Try it, everything will work out!</ ul>