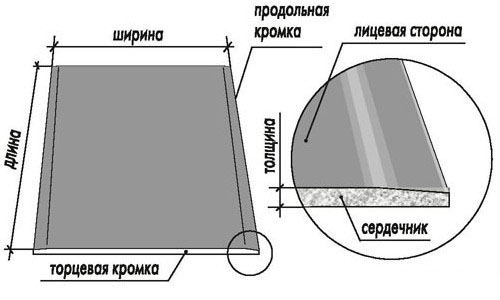

If you are planning a full renovation of your homeor office, you need to think through everything. No design will look good on uneven walls. In order to give them an aesthetic and neat look, you need to finish the walls with plasterboard. Drywall sheet diagram.Today, plasterboard is one of the most widely used materials in finishing works. It is used in the work of two thirds of the masters. And this choice is not accidental. Plasterboard itself is an excellent material for finishing. It can boast a number of advantages. Plasterboard is a kind of "sandwich" filled with gypsum. This is its base. The core. The front parts are made of cardboard. The material is produced in sheet form. The sizes for arranging walls with plasterboard can be:

Drywall sheet diagram.Today, plasterboard is one of the most widely used materials in finishing works. It is used in the work of two thirds of the masters. And this choice is not accidental. Plasterboard itself is an excellent material for finishing. It can boast a number of advantages. Plasterboard is a kind of "sandwich" filled with gypsum. This is its base. The core. The front parts are made of cardboard. The material is produced in sheet form. The sizes for arranging walls with plasterboard can be:

- length from 2.5 to 4.8 m;

- width from 1,2 to 1,3 m;

- thickness 0.8-2.4 cm.

Manufacturing plants produce three main types of plasterboard:

- standard (GCR);

- fireproof (GKLO);

- waterproof (GKLV).

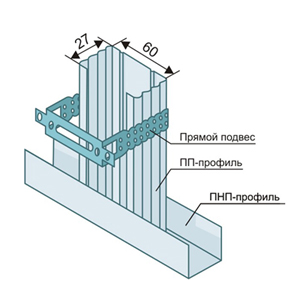

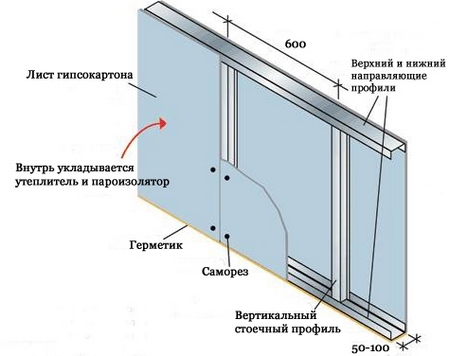

Profile fastening diagram.Fire-resistant plasterboard finishing is used for shafts, air ducts and communications. Waterproof ones are used in rooms with high humidity, such as bathrooms or kitchens. Tips and recommendations:

Profile fastening diagram.Fire-resistant plasterboard finishing is used for shafts, air ducts and communications. Waterproof ones are used in rooms with high humidity, such as bathrooms or kitchens. Tips and recommendations:

Materials, tools and equipment

For each type of work and cladding, it is necessary to prepare a set of tools, equipment and purchase materials. If you decide to finish the walls with plasterboard yourself, then you will need: Scheme of frameless method of finishing walls with plasterboard.

Scheme of frameless method of finishing walls with plasterboard.

- several types of profiles (on them is fastened plasterboard), namely the ceiling and guide. Dimensions of the first 60 * 27, the second 28 * 27;

- suspension of direct type;

- self-tapping screws;

- Screwdriver;

- scissors for metal;

- building level (preferably laser);

- roulette;

- a knife (with it, sheets of plasterboard are cut);

- twine or thick thread;

- plumb line.

Once all materials and equipment are prepared, you can begin work. Finishing with plasterboard is not a complicated process. There are several types of installation of plasterboard sheets:

- wireframe;

- frameless.

Return to Contents</a>

Features of the work by the wireframe method

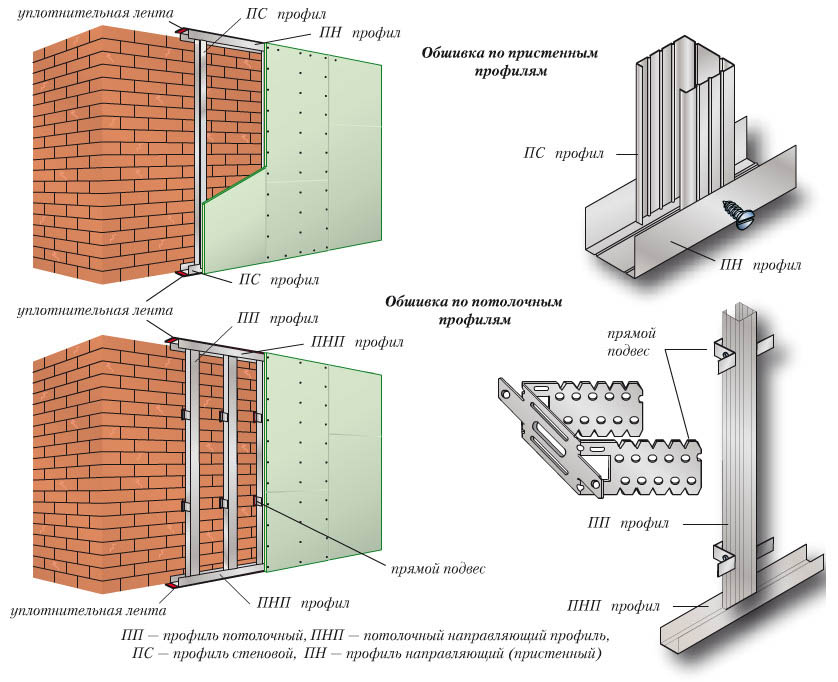

Frame technology for installing plasterboardincludes several stages: Stage 1. Making a frame for plasterboard. Its subsequent installation. To do this, you need to install guide-type profiles on the floor and ceiling. First, you need to mark the ceiling. Then the profiles are adjusted to size. Sometimes they need to be trimmed. The prepared profiles are fastened in the marked places. Scheme of wall covering with plasterboard onmetal frame. After some of the profiles are fixed to the ceiling, a plumb line is lowered. It allows you to determine the exact location of the remaining profiles, but already on the floor. They need to be fixed. As a result, you get a frame that has a limiter in the form of two guides. Stage 2. Installing ceiling profiles. They also need to be adjusted to size. Reference point - the height of the room. In other words, the distance between the upper and lower profile of the guide type. The calculation of ceiling profiles is made for three profiles for each sheet of drywall. Two are located at the edges, one - in the center. Important! Make sure that the edge of each sheet falls into the middle of the profile. This is necessary so that two sheets of drywall can be fixed to one profile. After you measure the distance between the ceiling profiles, vertical markings are applied to the wall along the previously installed plumb line. On these lines, you should fix the straight hangers. Ceiling profiles will be attached to them. If you do not know how many plumb lines should be prepared, you can use standard calculations. Their number directly depends on the height of the ceilings in the room. For an apartment with a standard layout, about 4 pieces will be required. Fastening of hangers to the walls is carried out with self-tapping screws. In order to strengthen the frame and give it reliability, all vertical posts must be secured with ceiling profiles. You also use self-tapping screws, but in addition to them, you will need fasteners, which are also called "crabs". Some craftsmen, in the absence of the latter, use cuttings from guide profiles.

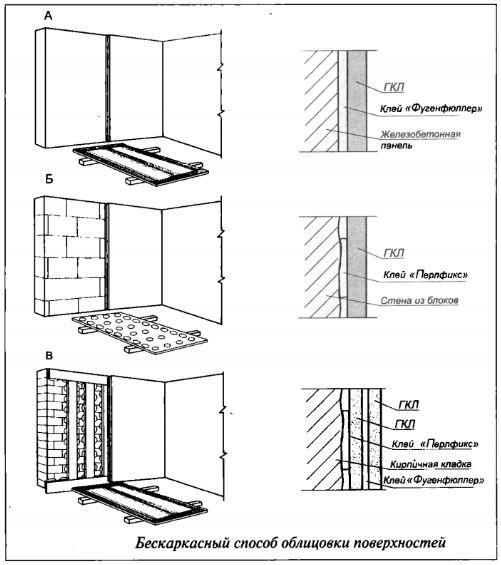

Scheme of wall covering with plasterboard onmetal frame. After some of the profiles are fixed to the ceiling, a plumb line is lowered. It allows you to determine the exact location of the remaining profiles, but already on the floor. They need to be fixed. As a result, you get a frame that has a limiter in the form of two guides. Stage 2. Installing ceiling profiles. They also need to be adjusted to size. Reference point - the height of the room. In other words, the distance between the upper and lower profile of the guide type. The calculation of ceiling profiles is made for three profiles for each sheet of drywall. Two are located at the edges, one - in the center. Important! Make sure that the edge of each sheet falls into the middle of the profile. This is necessary so that two sheets of drywall can be fixed to one profile. After you measure the distance between the ceiling profiles, vertical markings are applied to the wall along the previously installed plumb line. On these lines, you should fix the straight hangers. Ceiling profiles will be attached to them. If you do not know how many plumb lines should be prepared, you can use standard calculations. Their number directly depends on the height of the ceilings in the room. For an apartment with a standard layout, about 4 pieces will be required. Fastening of hangers to the walls is carried out with self-tapping screws. In order to strengthen the frame and give it reliability, all vertical posts must be secured with ceiling profiles. You also use self-tapping screws, but in addition to them, you will need fasteners, which are also called "crabs". Some craftsmen, in the absence of the latter, use cuttings from guide profiles. General diagram of fastening plasterboard to walls.Stage 3. Installing drywall. Attaching to the frame. For this, you will also need screws. But in this case, you need a special steel type. They are produced in an intense black color. Do not forget that drywall is not a hard material. Therefore, all work with sheets should be done carefully and without haste. Otherwise, you can damage it. In those places where there are joints or holes from screws, you need to carefully putty. Now let's consider the second, but no less common method - frameless. Compared to the previous method, it is less complicated and expensive. After all, you do not need to buy and attach profiles. For frameless technology, you should buy a special glue. Its composition is designed to most effectively fasten individual elements. There is a specific glue for each type of wall. That is, for a wood base, its own, and for a brick base, a different type is used. This is worth paying special attention to. Usually, such information is included in the instructions for use. This method is suitable for perfectly flat surfaces. But if there are small differences - it's not scary. It is enough to apply a thin layer of glue to the spatula, spread it over the surface, and then boldly glue the sheet of drywall. For this type of work, you will need a spatula with special notches. If the surface has fairly large differences, for example, a couple of cm, then the glue should be applied from the back of the drywall according to the principle of pancakes. And in cases with a difference of more than 2 cm, the frameless method should not be used. It is more correct and reliable to use the usual method. That is, the frame one. Return to the table of contents</a>

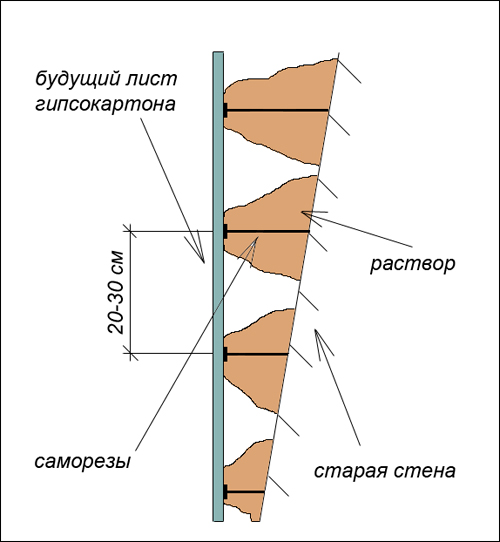

General diagram of fastening plasterboard to walls.Stage 3. Installing drywall. Attaching to the frame. For this, you will also need screws. But in this case, you need a special steel type. They are produced in an intense black color. Do not forget that drywall is not a hard material. Therefore, all work with sheets should be done carefully and without haste. Otherwise, you can damage it. In those places where there are joints or holes from screws, you need to carefully putty. Now let's consider the second, but no less common method - frameless. Compared to the previous method, it is less complicated and expensive. After all, you do not need to buy and attach profiles. For frameless technology, you should buy a special glue. Its composition is designed to most effectively fasten individual elements. There is a specific glue for each type of wall. That is, for a wood base, its own, and for a brick base, a different type is used. This is worth paying special attention to. Usually, such information is included in the instructions for use. This method is suitable for perfectly flat surfaces. But if there are small differences - it's not scary. It is enough to apply a thin layer of glue to the spatula, spread it over the surface, and then boldly glue the sheet of drywall. For this type of work, you will need a spatula with special notches. If the surface has fairly large differences, for example, a couple of cm, then the glue should be applied from the back of the drywall according to the principle of pancakes. And in cases with a difference of more than 2 cm, the frameless method should not be used. It is more correct and reliable to use the usual method. That is, the frame one. Return to the table of contents</a>

Recommendations on the frameless method

Scheme of wall alignment without a frame.The process of installing drywall in a frameless manner consists of several stages. Stage 1. Cleaning the surface from dirt. First, you need to remove dust and dirt from the walls. Stage 2. Priming. All walls should be thoroughly covered with a layer of primer. Stage 3. Applying adhesive. Advice! Do not apply adhesive to the entire wall. It is better to work in small areas. Apply adhesive strictly under each sheet of drywall. Stage 4. Gluing sheets. Glue is applied to the surface of the sheet (the opposite side from the front side). Then the sheet is pressed tightly against the prepared section of the wall. In order for each sheet to lie as evenly as possible, builders use a level. It is better to use a laser level, as it is more accurate in its measurements. Alignment occurs in the following way: light pressure is applied to the sheet on each side. And so on until the desired result is achieved. You can use a rubber hammer. After gluing the first sheet, take the next one. So until the work is completed. If the sheet size is not suitable, it is cut. As you can see, everything is quite simple. Drywall is easy to work with. It will not be difficult to decorate the walls with it. The most important rule is an accurate calculation. And do not forget, the main thing is to start. And the end result will exceed all expectations.

Scheme of wall alignment without a frame.The process of installing drywall in a frameless manner consists of several stages. Stage 1. Cleaning the surface from dirt. First, you need to remove dust and dirt from the walls. Stage 2. Priming. All walls should be thoroughly covered with a layer of primer. Stage 3. Applying adhesive. Advice! Do not apply adhesive to the entire wall. It is better to work in small areas. Apply adhesive strictly under each sheet of drywall. Stage 4. Gluing sheets. Glue is applied to the surface of the sheet (the opposite side from the front side). Then the sheet is pressed tightly against the prepared section of the wall. In order for each sheet to lie as evenly as possible, builders use a level. It is better to use a laser level, as it is more accurate in its measurements. Alignment occurs in the following way: light pressure is applied to the sheet on each side. And so on until the desired result is achieved. You can use a rubber hammer. After gluing the first sheet, take the next one. So until the work is completed. If the sheet size is not suitable, it is cut. As you can see, everything is quite simple. Drywall is easy to work with. It will not be difficult to decorate the walls with it. The most important rule is an accurate calculation. And do not forget, the main thing is to start. And the end result will exceed all expectations.