Houses made of foam concrete requirespecial interior finishing of the building. Finishing of walls from foam blocks requires compliance with the technology, otherwise all work will become unusable. A feature of this material is low moisture resistance, with an increase in which improper finishing of the walls leads to the proliferation of fungus and mold on the walls. The porosity of aerated concrete allows moisture to freely penetrate through pores and microcracks, destroying it over time. Incorrect finishing of foam concrete walls leadsto the growth of mold and mildew on the walls. To prevent these negative consequences for the building, it is necessary to carry out thorough waterproofing. The porous structure of foam concrete is characterized by low density. Because of this, the usual fasteners used in interior decoration cannot be firmly fixed in the wall. To work with the frame device, special dowels for foam concrete are required, which are commercially available. The smooth surface of foam concrete containing foam additives does not hold plaster compositions, and interior wall decoration requires mandatory reinforcement. All these features of walls made of foam blocks force the use of special technologies, and this increases the cost of interior decoration.

Incorrect finishing of foam concrete walls leadsto the growth of mold and mildew on the walls. To prevent these negative consequences for the building, it is necessary to carry out thorough waterproofing. The porous structure of foam concrete is characterized by low density. Because of this, the usual fasteners used in interior decoration cannot be firmly fixed in the wall. To work with the frame device, special dowels for foam concrete are required, which are commercially available. The smooth surface of foam concrete containing foam additives does not hold plaster compositions, and interior wall decoration requires mandatory reinforcement. All these features of walls made of foam blocks force the use of special technologies, and this increases the cost of interior decoration.

What works are carried out during the interior decoration?

The interior decoration consists of:

Depending on the choice of wall treatment method, the following will be required for the work: Installation of a ventilated facade.

Installation of a ventilated facade.

Tools required:

Return to Contents</a>

Technology of wall finishing from foam blocks with plasterboard

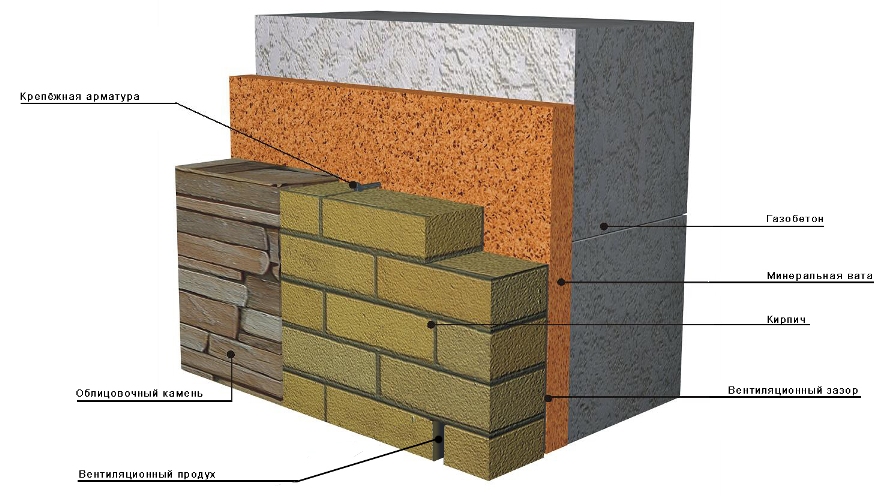

You can use it for finishing wallsfacing brick. When preparing to start waterproofing work, they choose either a waterproofing film or a primer, which is a good insulating agent. The seams between the blocks are puttied to eliminate drafts. If the external walls are planned to be plastered or tiled, then thermal insulation is carried out from the inside of the house. Foiled mineral wool is used for this. Basalt or fiberglass wool in the form of slabs is best suited for walls made of cellular concrete. They are more convenient to mount on the wall. When laying insulation from an aluminum profile, a frame is mounted, into the cells of which the insulation is placed. The width of the slabs corresponds to the profile step or is one to two centimeters wider. Then the insulation completely fills the space of the frame. Mineral wool slabs are laid with the foil inside the room and fixed to the wall with glue. After that, sheets of plasterboard are mounted on the frame. Such a wall can be covered with dense relief wallpaper that can be painted. Then the surface of the plasterboard is not puttied. They stop at carefully sealing the seams between the sheets. If the option with wallpaper for painting is not suitable, then the plasterboard is puttied over the entire area, after drying, it is leveled with sandpaper and painted. If possible, other necessary finishing works are carried out.

You can use it for finishing wallsfacing brick. When preparing to start waterproofing work, they choose either a waterproofing film or a primer, which is a good insulating agent. The seams between the blocks are puttied to eliminate drafts. If the external walls are planned to be plastered or tiled, then thermal insulation is carried out from the inside of the house. Foiled mineral wool is used for this. Basalt or fiberglass wool in the form of slabs is best suited for walls made of cellular concrete. They are more convenient to mount on the wall. When laying insulation from an aluminum profile, a frame is mounted, into the cells of which the insulation is placed. The width of the slabs corresponds to the profile step or is one to two centimeters wider. Then the insulation completely fills the space of the frame. Mineral wool slabs are laid with the foil inside the room and fixed to the wall with glue. After that, sheets of plasterboard are mounted on the frame. Such a wall can be covered with dense relief wallpaper that can be painted. Then the surface of the plasterboard is not puttied. They stop at carefully sealing the seams between the sheets. If the option with wallpaper for painting is not suitable, then the plasterboard is puttied over the entire area, after drying, it is leveled with sandpaper and painted. If possible, other necessary finishing works are carried out. Foam concrete walls inside the premises can beFinish with plaster. There is another option for working with plasterboard, when a wooden frame is used for interior finishing. Sheathing the interior walls with plasterboard sheets is the cheapest and most practical option of all available. All interior partitions can be made from it, filling it with special sealants for sound insulation. Before installing the wooden frame, a vapor barrier is laid on the wall to retain heat. The use of insulating film for internal wall insulation protects the insulation located on the outside of the house from steam and condensation. It protects plasterboard structures from moisture that occurs in heated rooms due to temperature changes. This film is recommended for all types of enclosing structures. It is used with all types of thermal insulation made of fiberglass, basalt wool, polystyrene foam, and foam concrete. When installing the frame, leave a distance of at least 5 cm between the foam concrete wall and the plasterboard to allow ventilation of the wall. The wooden blocks are fastened with special dowels. Return to contents</a>

Foam concrete walls inside the premises can beFinish with plaster. There is another option for working with plasterboard, when a wooden frame is used for interior finishing. Sheathing the interior walls with plasterboard sheets is the cheapest and most practical option of all available. All interior partitions can be made from it, filling it with special sealants for sound insulation. Before installing the wooden frame, a vapor barrier is laid on the wall to retain heat. The use of insulating film for internal wall insulation protects the insulation located on the outside of the house from steam and condensation. It protects plasterboard structures from moisture that occurs in heated rooms due to temperature changes. This film is recommended for all types of enclosing structures. It is used with all types of thermal insulation made of fiberglass, basalt wool, polystyrene foam, and foam concrete. When installing the frame, leave a distance of at least 5 cm between the foam concrete wall and the plasterboard to allow ventilation of the wall. The wooden blocks are fastened with special dowels. Return to contents</a>

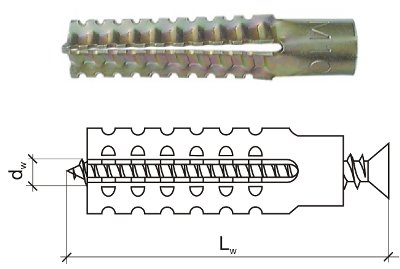

Which dowels are suitable for interior decoration?

For foam concrete you need to use special onesmetal dowels. Choosing the necessary dowels is a crucial moment for interior finishing. Without them, all the fasteners on the wall will not hold and all the finishing will fall off. There are two common types of this fastener. They can be made of metal or plastic. One type of dowel for foam blocks requires a pre-drilled hole in the wall, the other is screwed in without drilling. Fasteners made of plastic are suitable for most construction and installation works. They are not subject to aging and wear, and they are most often used to attach light household items to walls made of foam blocks. Their size is selected depending on the type of product and load. The recommended diameter is from 4 to 12 mm. A metal dowel is used with increased fire safety requirements. It is equipped with 4 spacer segments, and the external teeth increase its load-bearing capacity, it is used to attach various building structures. After the frame is ready, plasterboard sheets are attached to it and the walls are puttied as usual. Wallpaper can be glued to the finished walls; they will look great on this material. Return to contents</a>Technology of plastering walls made of foam concreteAnother option for interior finishing of walls made of foam blocks is traditional plastering. Before starting work, the walls are covered with a water-repellent primer. Then, using special dowels, a reinforcing mesh is attached and the wall surface is plastered on its basis. The work is carried out with a gypsum plaster mixture, which allows for the application of a thick layer. After complete drying, the wall is puttied, leveled and covered with finishing materials. This can be tiles or paints on a silicate or silicone basis. They have higher vapor permeability and will stay on the wall for a long time after application. Return to contents</a>

For foam concrete you need to use special onesmetal dowels. Choosing the necessary dowels is a crucial moment for interior finishing. Without them, all the fasteners on the wall will not hold and all the finishing will fall off. There are two common types of this fastener. They can be made of metal or plastic. One type of dowel for foam blocks requires a pre-drilled hole in the wall, the other is screwed in without drilling. Fasteners made of plastic are suitable for most construction and installation works. They are not subject to aging and wear, and they are most often used to attach light household items to walls made of foam blocks. Their size is selected depending on the type of product and load. The recommended diameter is from 4 to 12 mm. A metal dowel is used with increased fire safety requirements. It is equipped with 4 spacer segments, and the external teeth increase its load-bearing capacity, it is used to attach various building structures. After the frame is ready, plasterboard sheets are attached to it and the walls are puttied as usual. Wallpaper can be glued to the finished walls; they will look great on this material. Return to contents</a>Technology of plastering walls made of foam concreteAnother option for interior finishing of walls made of foam blocks is traditional plastering. Before starting work, the walls are covered with a water-repellent primer. Then, using special dowels, a reinforcing mesh is attached and the wall surface is plastered on its basis. The work is carried out with a gypsum plaster mixture, which allows for the application of a thick layer. After complete drying, the wall is puttied, leveled and covered with finishing materials. This can be tiles or paints on a silicate or silicone basis. They have higher vapor permeability and will stay on the wall for a long time after application. Return to contents</a>

Finishing of walls from foam concrete

Finishing methods are already being usedfinished walls. For cosmetic finishing, you can use various materials. Each of them has its own specifics in work. One of such materials can be cork slabs. Cork requires that the walls are perfect. The base of the wall must be dry and clean, without defects, high-quality plastered. Before starting to finish the walls, the cork is kept for about 24 hours at room temperature in an unpacked form. Before laying, the walls are treated with a deep penetration primer, after which cork plates are glued to them using special glue. For finishing work, cladding with clapboard or other decorative panels can be used. The use of clapboard as a finish requires treatment with an antiseptic and finishing material, and the lathing of bars. Fastening of this finishing material is carried out with special clamps, firmly fixing the cladding to the frame. Insulation is laid between the clapboard and the wall and a vapor barrier is arranged. During the finishing process, it is necessary to provide for the laying of electrical wiring. To preserve the appearance, the lining is treated with varnish. The interior decoration of a house made of foam blocks can be done with wooden panels. The finishing technology is the same as for lining. The choice of any finishing option depends on the wishes of the owner of the house and his financial capabilities. A properly finished house made of foam concrete blocks will last as long as one made of other materials.