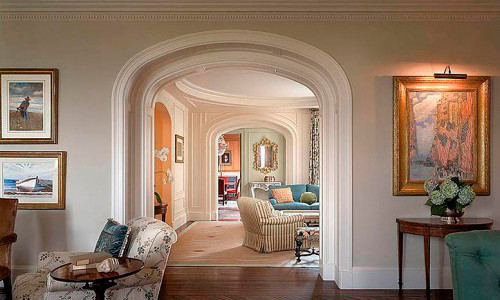

Choosing this or that interior design, eacha man involuntarily confronts with a choice what to prefer: a classic or a novelty. What kind of flavor to add? Do you install a conventional door or make an arch? If you chose the latter, but do not know where to start, you can answer the question below about how to make an arch in the wall.  Arch in the wall will help to make the interior of the roommore interesting. In order to make an aesthetic and accurate arch, you should use drywall. Firstly, because the material itself meets all modern standards of quality. And secondly, working with him will not bring difficulties. The wall on which the arch should be located, usually performs a connecting function with an adjacent room. Of course, those who first encounter repair, it may seem that this is a very complex and time-consuming process. So, what you need to know about the arches? The standard arch in width is 2 m. These are ideal parameters. They are suitable for the usual doorway, which can be found in every house, panel type. Such openings in private houses are not less common.

Arch in the wall will help to make the interior of the roommore interesting. In order to make an aesthetic and accurate arch, you should use drywall. Firstly, because the material itself meets all modern standards of quality. And secondly, working with him will not bring difficulties. The wall on which the arch should be located, usually performs a connecting function with an adjacent room. Of course, those who first encounter repair, it may seem that this is a very complex and time-consuming process. So, what you need to know about the arches? The standard arch in width is 2 m. These are ideal parameters. They are suitable for the usual doorway, which can be found in every house, panel type. Such openings in private houses are not less common.

Tools and materials

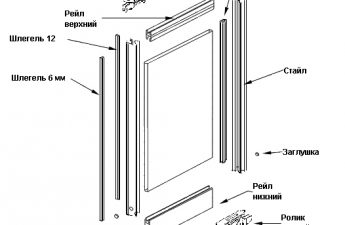

To make the frame, which is required for the arch, you need to prepare the following set of tools and materials:  The structure of the arch framework.

The structure of the arch framework.

After you have prepared the necessary set, you can start making the arch. Back to contents</a>

How to properly make an arch of plasterboard: features

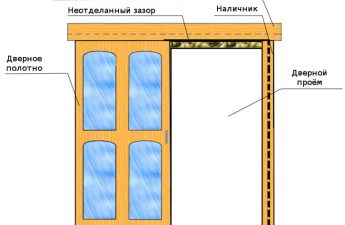

First you need to determine the radius of the arch. He is selected individually. There is no single size.  Scheme fixing gypsum cardboard to the frame of the arch. Before starting work, you need to imagine what the future arch looks like. How harmonious it will fit in the interior. Do not make its edges much rounded, since you will not only reduce its volume, but it will be too simple to look like this. Some people prefer the arch in the form of a right circle, but they can eventually face such a problem as an opening that is unsuitable for bulky items. You can not bring a massive cabinet into the room without damaging the edges of the arch or wall. The optimal radius option is slightly rounded. Ideally, it should coincide in width with the wall opening. After you have determined this value, on the sheet of drywall with the usual rope and pencil, you should make a markup. In this case, the rope is used as a self-made compass. The center of the sheet is the point at which the axis will pass. Back to contents</a>

Scheme fixing gypsum cardboard to the frame of the arch. Before starting work, you need to imagine what the future arch looks like. How harmonious it will fit in the interior. Do not make its edges much rounded, since you will not only reduce its volume, but it will be too simple to look like this. Some people prefer the arch in the form of a right circle, but they can eventually face such a problem as an opening that is unsuitable for bulky items. You can not bring a massive cabinet into the room without damaging the edges of the arch or wall. The optimal radius option is slightly rounded. Ideally, it should coincide in width with the wall opening. After you have determined this value, on the sheet of drywall with the usual rope and pencil, you should make a markup. In this case, the rope is used as a self-made compass. The center of the sheet is the point at which the axis will pass. Back to contents</a>

How is the layout of the future arch carried out?

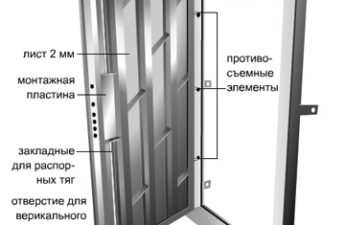

In the center of the sheet you put a mark. At this point you need to screw in the screw. On its base under the bonnet, tie a string or a thin rope. Tie a pencil to the end of the cord. After that, pull the cord and pencil along the sheet of drywall. At the end you will get a marked outline. After you have done the markup, you need to cut off excess plasterboard. It is enough to use an ordinary knife. Some people prefer to use a hacksaw.  Dimensions of arches depending on the width of the dooropenings. Cut gypsum cardboard carefully. First it is put on the floor. You can use the table, but not all homes have tables of suitable size. Before you start cutting, the floor should be covered with paper. This will protect it from additional dust and dirt. Cutting drywall, you get two elements, one of which will perform the function of a template, and the second will be a mirror-reflecting part. After completing the stage of manufacturing blanks, you can begin assembling the frame. It is made of metal profiles. The dimensions of the frame are the values measured by the curve. The profile of the guide type you must attach to both the ceiling and the walls, in the form of parallel strips. The thickness of the arch is the distance between the profiles laid parallel to each other. Ideally, it should not exceed 20 cm. Be sure to consider the thickness of drywall sheets. Attaching it to the sheets is done using self-tapping screws. The distance between them should be kept within 25 cm. The next step is to measure the length of the bend. After you have made measurements, a copy of the arch bend is made from the profile of the guide type. For this, cuts are made on the profile using metal scissors. The made bending frame is fixed to the arch with self-tapping screws. They can be screwed in at a small interval. Then you need to make jumpers. They are needed for the arch to become stiff and strong. To do this, a rack-type profile is cut into strips, the length of which coincides with the thickness of the arch. The frequency of jumper use is 1 unit. for every 10 cm. After the manufacture of the frame and its installation, it is possible to begin to coat it with arched plasterboard. It is thinner than the material used previously. Therefore, you need to work with it carefully. To strip the gypsum board in the creation of the bend is not broken, it is pre-wetted with water and set in a slope on any surface. For this purpose, you can use a conventional chair. After completing this trick, after a while, you will get a bent strip of drywall. To give it the right angle, you should use a needle-type roller. Do not strongly wet the sheet. It can be saturated with water and break. The final stage of making the arch is the fastening of the arched corners on the edges. They are needed in order to accurately apply the putty and adjust it to the plane of the walls. To do this, put a sickle on the joints, and then shpaklyuyut. Back to contents</a>

Dimensions of arches depending on the width of the dooropenings. Cut gypsum cardboard carefully. First it is put on the floor. You can use the table, but not all homes have tables of suitable size. Before you start cutting, the floor should be covered with paper. This will protect it from additional dust and dirt. Cutting drywall, you get two elements, one of which will perform the function of a template, and the second will be a mirror-reflecting part. After completing the stage of manufacturing blanks, you can begin assembling the frame. It is made of metal profiles. The dimensions of the frame are the values measured by the curve. The profile of the guide type you must attach to both the ceiling and the walls, in the form of parallel strips. The thickness of the arch is the distance between the profiles laid parallel to each other. Ideally, it should not exceed 20 cm. Be sure to consider the thickness of drywall sheets. Attaching it to the sheets is done using self-tapping screws. The distance between them should be kept within 25 cm. The next step is to measure the length of the bend. After you have made measurements, a copy of the arch bend is made from the profile of the guide type. For this, cuts are made on the profile using metal scissors. The made bending frame is fixed to the arch with self-tapping screws. They can be screwed in at a small interval. Then you need to make jumpers. They are needed for the arch to become stiff and strong. To do this, a rack-type profile is cut into strips, the length of which coincides with the thickness of the arch. The frequency of jumper use is 1 unit. for every 10 cm. After the manufacture of the frame and its installation, it is possible to begin to coat it with arched plasterboard. It is thinner than the material used previously. Therefore, you need to work with it carefully. To strip the gypsum board in the creation of the bend is not broken, it is pre-wetted with water and set in a slope on any surface. For this purpose, you can use a conventional chair. After completing this trick, after a while, you will get a bent strip of drywall. To give it the right angle, you should use a needle-type roller. Do not strongly wet the sheet. It can be saturated with water and break. The final stage of making the arch is the fastening of the arched corners on the edges. They are needed in order to accurately apply the putty and adjust it to the plane of the walls. To do this, put a sickle on the joints, and then shpaklyuyut. Back to contents</a>

How is the arch treated after production?

After the design of the arch is ready andattached to the wall, it is plastered with plasterboard. Then it will be necessary to perform works on surface refinement. First it is covered with a coat of primer. Immediately after its application, work should be suspended. It is necessary that the primer is completely dry. The next stage is puttying. It is necessary in order to remove the irregularities and small holes that arise during the work. When the putty dries, the arch is cleaned and proceeds to the finishing works. By the way, if you want to make built-in illumination in the arch, then holes for spot lights should be done in advance. In order to make an arch in the room, do not make great efforts and lose a large sum of money. But despite this, many people often turn to professionals. How to make an arch without resorting to the help of builders is a question that worries many people. To save on construction work, you will need to prepare a minimal set of materials and tools and some time to make an arch in the wall. At you all necessarily it will turn out.