One of the main stages of construction is considered to be the erection of walls. Various materials are used for this, including foam blocks. Professionals know how to plaster walls from foam blocks. When performing plastering work on walls made of foam blocks, use a reinforced mesh to ensure reliable adhesion of the mortar.

When performing plastering work on walls made of foam blocks, use a reinforced mesh to ensure reliable adhesion of the mortar.

Main advantages

There are some advantages to walls made of foam blocks:

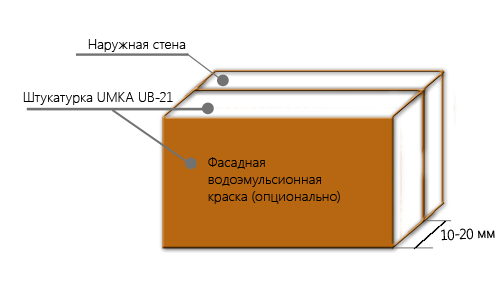

Scheme of plastering foam concrete.Experts say that there are no difficulties in processing such material. For finishing foam concrete, plaster, paints, tiles are used. from foam blocks is produced using special mixtures. Such finishing works have some advantages:

Scheme of plastering foam concrete.Experts say that there are no difficulties in processing such material. For finishing foam concrete, plaster, paints, tiles are used. from foam blocks is produced using special mixtures. Such finishing works have some advantages:

Return to Contents</a>

Necessary materials and tools

Plastering walls will require the use of tools and materials such as: Tools for plastering walls.

Tools for plastering walls.

- mesh plastering;

- primer;

- the building mix is dry;

- washers, dowels, nails;

- putty knife;

- drill or building mixer;

- level;

- a container for diluting the mixture;

- plumb bob;

- brushes of different sizes;

- chisel;

- knife;

- metal brush;

- rule.

Return to Contents</a>

Step-by-step instruction

The foam block is processed using a specialdeveloped materials, information about this is indicated on the packaging. Experts recommend using plaster and primer with certain properties and the ability to deeply penetrate the surface (BOLARS, Knauf, IVSIL, UNIS and Prime-Grunt) to perform such work. Plaster can be prepared at home from chalk, cement and lime, but the resulting mixture will not be resistant to low temperatures, fire and will not have other properties inherent in professional products. Experts recommend using products from the following manufacturers: PROFIT KONTAKT MN, EuroMix, Ceresit CT24 and Maska mix. Materials of this quality are suitable for finishing the internal and external surfaces of the building. Technology of plastering a wall made of foam concrete.It is necessary to work with the compositions carefully, as a thick layer can deprive foam blocks of moisture resistance. The thickness of the finishing layer should not exceed 2-3 cm. Before purchasing materials, it is recommended to make sure that they provide a sufficient level of adhesion, as this indicator is considered one of the most important when plastering foam concrete. The quality of such work on the external surfaces of buildings will be higher if you use primers that contain hydrophobic components. An additional layer of impregnation with a water-repellent effect is applied over the plaster. This technology for finishing walls prevents cracks in the outer coating and cracking of the plaster underneath. You can enhance the adhesion of the coating to the surface of the foam block using a fiberglass mesh, which is resistant to aggressive alkaline environments. In this case, the strength of the formed surfaces will be higher. Experts advise using a reinforced mesh only in problem areas (door and window openings, at joints). Experts recommend performing finishing work after detailed familiarization with how to plaster walls from foam blocks. Preliminary prepare the walls by cleaning them from layers of old plaster or paint using a metal brush, which can be attached to a drill for convenience.

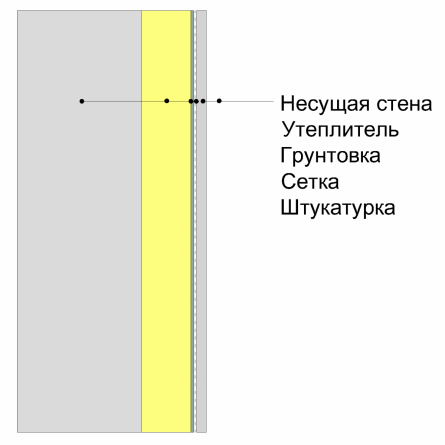

Technology of plastering a wall made of foam concrete.It is necessary to work with the compositions carefully, as a thick layer can deprive foam blocks of moisture resistance. The thickness of the finishing layer should not exceed 2-3 cm. Before purchasing materials, it is recommended to make sure that they provide a sufficient level of adhesion, as this indicator is considered one of the most important when plastering foam concrete. The quality of such work on the external surfaces of buildings will be higher if you use primers that contain hydrophobic components. An additional layer of impregnation with a water-repellent effect is applied over the plaster. This technology for finishing walls prevents cracks in the outer coating and cracking of the plaster underneath. You can enhance the adhesion of the coating to the surface of the foam block using a fiberglass mesh, which is resistant to aggressive alkaline environments. In this case, the strength of the formed surfaces will be higher. Experts advise using a reinforced mesh only in problem areas (door and window openings, at joints). Experts recommend performing finishing work after detailed familiarization with how to plaster walls from foam blocks. Preliminary prepare the walls by cleaning them from layers of old plaster or paint using a metal brush, which can be attached to a drill for convenience. Scheme of a wall with plastering over insulation.The surface must dry after applying the first layer. Then apply an additional composition (to improve adhesion). The walls must be primed well so that the prepared building mixture holds firmly. It is recommended to prepare the composition in a small container. You can mix it with a regular drill with a suitable attachment or with a construction mixer. Then, plaster is applied to the prepared walls made of foam blocks with a spatula. The technology for applying it to foam blocks is no different from working with other surfaces. The composition must be distributed with a spatula from the bottom up. The layer of the applied mixture should not be more than 20 mm. If the wall is erected from cast blocks, then it is recommended to fasten a fiberglass or metal mesh with nails and dowels (to increase strength). The mesh is pre-stretched and closely fixed to the wall surface. Its appearance depends on what layer of the composition will be applied. After applying the 1st layer, you must wait for the mixture to dry and re-prime the surface. Then you need to level the finishing layer, additionally plastering and leaving the surface to dry. The second layer of the mixture should be thinner than the first. You can start finishing work with wallpaper, paint or tiles only after the plaster has completely hardened. Walls made of aerated concrete have higher strength and thermal insulation. The material is easy to process, and less cement is used for its production.

Scheme of a wall with plastering over insulation.The surface must dry after applying the first layer. Then apply an additional composition (to improve adhesion). The walls must be primed well so that the prepared building mixture holds firmly. It is recommended to prepare the composition in a small container. You can mix it with a regular drill with a suitable attachment or with a construction mixer. Then, plaster is applied to the prepared walls made of foam blocks with a spatula. The technology for applying it to foam blocks is no different from working with other surfaces. The composition must be distributed with a spatula from the bottom up. The layer of the applied mixture should not be more than 20 mm. If the wall is erected from cast blocks, then it is recommended to fasten a fiberglass or metal mesh with nails and dowels (to increase strength). The mesh is pre-stretched and closely fixed to the wall surface. Its appearance depends on what layer of the composition will be applied. After applying the 1st layer, you must wait for the mixture to dry and re-prime the surface. Then you need to level the finishing layer, additionally plastering and leaving the surface to dry. The second layer of the mixture should be thinner than the first. You can start finishing work with wallpaper, paint or tiles only after the plaster has completely hardened. Walls made of aerated concrete have higher strength and thermal insulation. The material is easy to process, and less cement is used for its production.