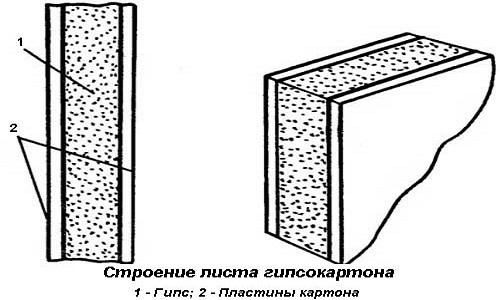

Installation of plasterboard on walls is carried out with the help offrame or frameless method. For finishing the shower, loggia, terrace, use plasterboard or gypsum fiber boards. They are installed on profile gratings. Fire-resistant plasterboard and gypsum fiber strips are mounted on the walls in the corridor, hall and foyer. A waterproof analogue is laid in the kitchen. The material is selected taking into account the loads and operating conditions. Structure of the GLC leaf.

Structure of the GLC leaf.

Frameless technique

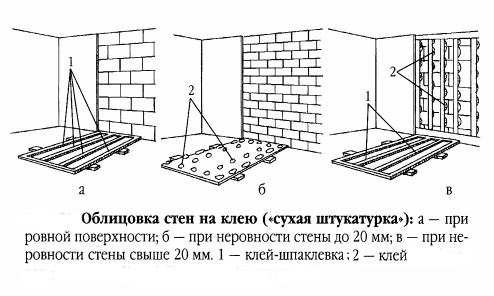

Using a plasterboard wall, space is createdfor the arrangement of various communications. At the same time, thermal and noise insulation are provided. Drywall levels the surface for subsequent finishing works. Its installation using a frameless method is carried out using 12 mm thick slabs. Experts distinguish 3 ways to mount drywall using frameless technology. If there are minor irregularities on the wall surface (4 mm), then the sheets are fixed using a gypsum-based putty. If this figure fluctuates between 4-20 mm, then the drywall is mounted using glue. The substance is applied to the material in lines with a step of 35 cm. If the wall irregularities do not exceed 4 cm, then the slabs are divided into strips 10 cm wide. The material is fixed to the surface with glue. The next stage involves the installation of solid gypsum boards: they are attached to the previous layer with putty. Before erecting a partition from slabs, the depth of the irregularities is determined. Tool for working with plasterboard.Then the technology for constructing the structure is selected and markings are applied to the surface. The coating is dried and cleaned of various stains, the wall is primed. The plasterboard is cut to the required dimensions, holes are made in the material for communications. The working surface must meet the following requirements:

Tool for working with plasterboard.Then the technology for constructing the structure is selected and markings are applied to the surface. The coating is dried and cleaned of various stains, the wall is primed. The plasterboard is cut to the required dimensions, holes are made in the material for communications. The working surface must meet the following requirements:

- no deformation and condensation;

- strength;

- presence of protection against humidity.

If the walls are made of plasterboard, the firsttechnique, then putty is applied to the material. In advance, you will need to buy a notched trowel, a level, and a tape measure. Installation work begins from the corner. If the sheets are attached to a wooden surface, then special nails are used. with unevenness from 4-20 mm involves laying the slabs close to each other. The remaining glue is removed. To finish surfaces with unevenness of 40 mm, you will need to cut strips 40-60 cm wide. Installation of gypsum boards is carried out in a vertical position. Return to the table of contents</a>

Wireframe technique

Example diagram of marking sheets of plasterboard onwalls. Walls made of slabs can be erected using sheathing. The frame is made of ceiling, wall or cap profile. Construction using a frame is carried out in two ways. The technology in question is used when there are surface irregularities of up to 10 cm. The slabs are mounted to a metal or wooden frame. The material is attached to the first sheathing with screws or dowels. The rack profile is installed with a step of 60 cm. The use of thick slabs requires a step of 30-40 cm. If there are irregularities of up to 10 cm on the wall, then installation work is carried out using direct hangers, ceiling and guide profiles. The latter elements are fixed with screws or dowels with a step of 100 cm. For the installation of ceiling profiles, direct hangers with a step of 150 cm are used.

Example diagram of marking sheets of plasterboard onwalls. Walls made of slabs can be erected using sheathing. The frame is made of ceiling, wall or cap profile. Construction using a frame is carried out in two ways. The technology in question is used when there are surface irregularities of up to 10 cm. The slabs are mounted to a metal or wooden frame. The material is attached to the first sheathing with screws or dowels. The rack profile is installed with a step of 60 cm. The use of thick slabs requires a step of 30-40 cm. If there are irregularities of up to 10 cm on the wall, then installation work is carried out using direct hangers, ceiling and guide profiles. The latter elements are fixed with screws or dowels with a step of 100 cm. For the installation of ceiling profiles, direct hangers with a step of 150 cm are used. Construction of a metal frameplasterboard. To assemble a plasterboard wall frame, each part of the sheathing is marked. A sealant is applied to the surface or a sealing tape is glued. The guide profiles are fixed taking into account the markings and with a step of 110 cm. The racks are fastened with a plumb line. A distance of 60 cm is observed. Rivets are used to fix these elements. Heat and sound insulation material is placed in the frame and communications are fixed. Rack profiles are used to install the door frame and window. They are fixed to the floor and ceiling. Then the slabs are fastened to the sheathing and the seams are putty. A primer is applied to the wall. The next stage involves the installation of sockets and switches. For better fixation of the seams, a reinforcing tape is used, otherwise a special mesh is laid at the joints of the gypsum board. Return to contents</a>

Construction of a metal frameplasterboard. To assemble a plasterboard wall frame, each part of the sheathing is marked. A sealant is applied to the surface or a sealing tape is glued. The guide profiles are fixed taking into account the markings and with a step of 110 cm. The racks are fastened with a plumb line. A distance of 60 cm is observed. Rivets are used to fix these elements. Heat and sound insulation material is placed in the frame and communications are fixed. Rack profiles are used to install the door frame and window. They are fixed to the floor and ceiling. Then the slabs are fastened to the sheathing and the seams are putty. A primer is applied to the wall. The next stage involves the installation of sockets and switches. For better fixation of the seams, a reinforcing tape is used, otherwise a special mesh is laid at the joints of the gypsum board. Return to contents</a>

Additional work

Scheme of fastening plasterboard with glue.Plasterboard walls can be erected using wooden slats. The presence of crumbling plaster and significant irregularities requires the use of such a technique. Glue is used to fix the slabs. The thickness of the plasterboard should be 12.5 mm. The size of the wooden slats is 50x30 mm. They are installed using screws or dowels with a step of 10 cm. To align the main risers located vertically, slats of the appropriate length are used. Additional insulation and soundproofing are arranged using glass wool or mineral wool. The slabs are attached to the frame with screws 3.5 cm long and with a step of 2.5 cm. If the installation of a plasterboard wall is carried out using the free-standing GKL method, then the frame is faced on one side. To fix the product, use 2.5 cm long self-tapping screws (for metal lathing) or 3.5 cm screws (for a wooden frame). Wiring under the gypsum board is laid before laying and before insulation work. The cable is laid in a metal sleeve or in a plastic corrugated pipe. The electric cable is preliminarily laid along the ceiling and walls. This will require a hammer drill and a concrete drill. Holes are cut in the slabs for lighting fixtures. Sockets are installed after laying the slabs. Switches, sockets, spotlights are installed after finishing work is completed. Concealed installation of communications and leveling of walls involve fastening the drywall with special brackets. The profile is fixed with acoustic analogs with a step of 125 cm. If the frame is made of wooden slats, then the fasteners are mounted with a step of 80 cm. The next stage involves finishing the wall from drywall. Such work can be done by yourself.</ ul>

Scheme of fastening plasterboard with glue.Plasterboard walls can be erected using wooden slats. The presence of crumbling plaster and significant irregularities requires the use of such a technique. Glue is used to fix the slabs. The thickness of the plasterboard should be 12.5 mm. The size of the wooden slats is 50x30 mm. They are installed using screws or dowels with a step of 10 cm. To align the main risers located vertically, slats of the appropriate length are used. Additional insulation and soundproofing are arranged using glass wool or mineral wool. The slabs are attached to the frame with screws 3.5 cm long and with a step of 2.5 cm. If the installation of a plasterboard wall is carried out using the free-standing GKL method, then the frame is faced on one side. To fix the product, use 2.5 cm long self-tapping screws (for metal lathing) or 3.5 cm screws (for a wooden frame). Wiring under the gypsum board is laid before laying and before insulation work. The cable is laid in a metal sleeve or in a plastic corrugated pipe. The electric cable is preliminarily laid along the ceiling and walls. This will require a hammer drill and a concrete drill. Holes are cut in the slabs for lighting fixtures. Sockets are installed after laying the slabs. Switches, sockets, spotlights are installed after finishing work is completed. Concealed installation of communications and leveling of walls involve fastening the drywall with special brackets. The profile is fixed with acoustic analogs with a step of 125 cm. If the frame is made of wooden slats, then the fasteners are mounted with a step of 80 cm. The next stage involves finishing the wall from drywall. Such work can be done by yourself.</ ul>