The life of a modern person is inextricably linked withconstant noises and sounds. This problem has especially affected residents of megacities. However, not all noises are pleasant for the human ear. While some can be perceived adequately, others cause hostility. These include screams and ringing coming from neighbors. For this reason, it is very important to install high-quality soundproofing in your home. It will help make any room quiet, calm and serene. The nervous system of the owners will be in perfect order. Soundproofing in the house. How to soundproof walls? To do this, you need to know the features of the materials, the uniqueness of their installation, the required number of layers and other important nuances.

Soundproofing in the house. How to soundproof walls? To do this, you need to know the features of the materials, the uniqueness of their installation, the required number of layers and other important nuances.

Basic materials for soundproofing

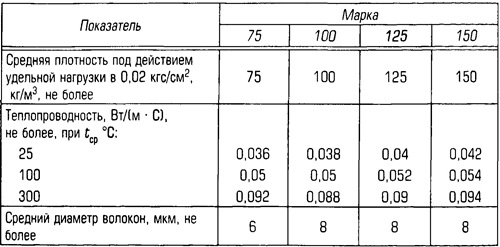

As materials that provideprotection from extraneous noise, glass wool, mineral wool and other mixtures of combined compositions are often used. Among modern materials, glass wool has earned special trust. It consists of fiberglass and mineral wool. This type of material is distinguished by its strength, flexibility, and ability to withstand vibrations well. Characteristics of mineral wool.Soundproofing of walls can be done using a classic version of the material. This is mineral wool. It combines excellent noise reduction properties and an excellent base for thermal insulation. The selected material will provide a strong filling, environmental friendliness, and the absence of unwanted harmful impurities. It does not cause allergies. It is also worth noting the ZIPS panels, which are a combined material based on gypsum fiber and mineral wool. Their installation does not require preliminary surface preparation in the form of making frames. However, they significantly reduce the area of the rooms. These panels are classified as heavy bases, as a result of which the partitions are the most durable and strong. Soundproofing of walls can be improved using plasterboard sheets. This material will provide good sound absorption. It will provide the walls with a perfect base for making walls and partitions. Return to contents</a>

Characteristics of mineral wool.Soundproofing of walls can be done using a classic version of the material. This is mineral wool. It combines excellent noise reduction properties and an excellent base for thermal insulation. The selected material will provide a strong filling, environmental friendliness, and the absence of unwanted harmful impurities. It does not cause allergies. It is also worth noting the ZIPS panels, which are a combined material based on gypsum fiber and mineral wool. Their installation does not require preliminary surface preparation in the form of making frames. However, they significantly reduce the area of the rooms. These panels are classified as heavy bases, as a result of which the partitions are the most durable and strong. Soundproofing of walls can be improved using plasterboard sheets. This material will provide good sound absorption. It will provide the walls with a perfect base for making walls and partitions. Return to contents</a>

List of required tools

List of necessary tools: level, screwdriver, hammer, grinder, hammer drill, screwdriver, jigsaw. The following tools will be required for installation work:

List of necessary tools: level, screwdriver, hammer, grinder, hammer drill, screwdriver, jigsaw. The following tools will be required for installation work:

- Screwdriver;

- perforator;

- Bulgarian;

- electric jigsaw;

- saws for metal and wood surfaces;

- a hammer;

- A stapler;

- knife;

- level;

- roller;

- screwdriver;

- spatulas;

- fastening elements;

- gloves and respirator.

Return to Contents</a>

Elementary ways to improve the sound insulation of walls

The design of partitions and their connection betweenyourself. How to improve the soundproofing of the walls in the apartment? Simple and complex methods are used for this. The first finishing option is the moment of sealing the joints on the outside of the building. After all, such cracks lead to a decrease in the level of sound isolation. Such manipulations are rarely carried out indoors. To build such a device, you should clean the wall covering, seal the cracks and seal the joints. Do not forget about the window openings, which have a large number of such cracks. You can also strengthen the switches and sockets. Here you can use several methods. One of them is associated with dismantling the sockets and switches and installing new ones that overlap the plane. Another way is to purchase a certain device such as a box with special curtains for high-quality sound insulation. Carpets, built-in furniture and devices made of plasterboard absorb sounds well. As a result, you can originally decorate the interior and provide protection from unnecessary air vibrations. Return to the table of contents</a>

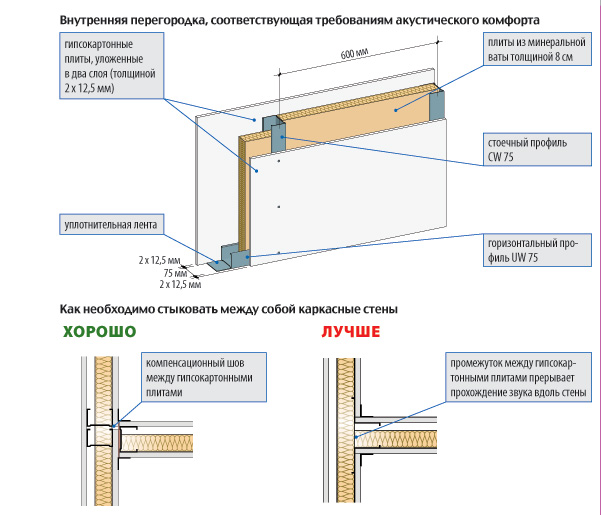

The design of partitions and their connection betweenyourself. How to improve the soundproofing of the walls in the apartment? Simple and complex methods are used for this. The first finishing option is the moment of sealing the joints on the outside of the building. After all, such cracks lead to a decrease in the level of sound isolation. Such manipulations are rarely carried out indoors. To build such a device, you should clean the wall covering, seal the cracks and seal the joints. Do not forget about the window openings, which have a large number of such cracks. You can also strengthen the switches and sockets. Here you can use several methods. One of them is associated with dismantling the sockets and switches and installing new ones that overlap the plane. Another way is to purchase a certain device such as a box with special curtains for high-quality sound insulation. Carpets, built-in furniture and devices made of plasterboard absorb sounds well. As a result, you can originally decorate the interior and provide protection from unnecessary air vibrations. Return to the table of contents</a>

Technology of making the basis for soundproofing

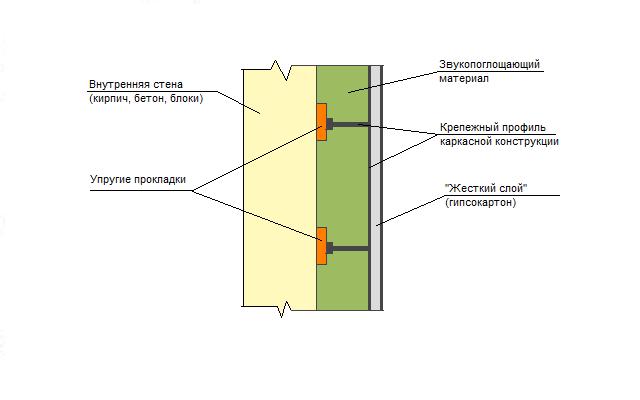

Scheme of soundproofing walls using plasterboard.As soon as the necessary material is purchased, you can begin installation. A multi-layer structure gives good results. This work will involve going through several stages.

Scheme of soundproofing walls using plasterboard.As soon as the necessary material is purchased, you can begin installation. A multi-layer structure gives good results. This work will involve going through several stages.

At first glance, such work may seemmay seem like something super complicated, but it is not. Having decided to hold such events once, it is important to have patience and endurance. And then the peace and quiet of the home will be ensured. Return to contents</a>

Number of filler layers

You can improve the sound insulation of walls bymultilayer construction. Often it combines 2 such layers. The best results can be achieved by connecting plasterboard and gypsum fiber. These bases have different densities, but a similar structure. The joints of partitions, floors and ceilings also need to be sealed. For this, silicone or other sealant with a plastic base is used. Return to contents</a>

Principles of soundproofing

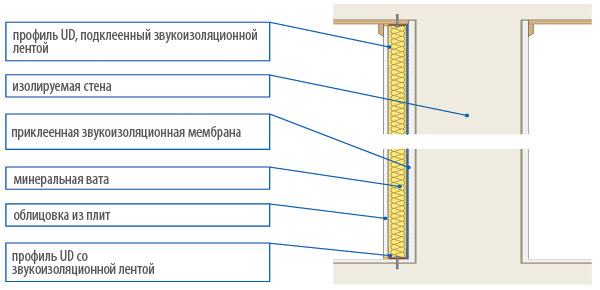

Soundproofing of internal partitions.Soundproofing can be done qualitatively using mineral wool, polymer insulators, and cork wood layers. In order to obtain the best indicators, a combination of a cork base and coconut fibers is used. In this case, a hard and flexible material is used, which makes the device of the highest quality. When laying such layers, you need to take care of careful planning and marking of the frame. The smallest height should be 5 cm. Then, a guide profile is attached over the entire area, onto which a soundproofing seal is glued. The main difficulty of this stage is associated with the density of the laid layers. They should be fixed so that the contact of the walls, ceiling, and floor is as close as possible. As soon as such a device is installed, you can attach the U-shaped fasteners. They are reinforced through the soundproofing plate to the main ceiling. The presented installation scheme using plasterboard helps to create overall comfort in the room or isolated room. Return to contents</a>

Soundproofing of internal partitions.Soundproofing can be done qualitatively using mineral wool, polymer insulators, and cork wood layers. In order to obtain the best indicators, a combination of a cork base and coconut fibers is used. In this case, a hard and flexible material is used, which makes the device of the highest quality. When laying such layers, you need to take care of careful planning and marking of the frame. The smallest height should be 5 cm. Then, a guide profile is attached over the entire area, onto which a soundproofing seal is glued. The main difficulty of this stage is associated with the density of the laid layers. They should be fixed so that the contact of the walls, ceiling, and floor is as close as possible. As soon as such a device is installed, you can attach the U-shaped fasteners. They are reinforced through the soundproofing plate to the main ceiling. The presented installation scheme using plasterboard helps to create overall comfort in the room or isolated room. Return to contents</a>

Typical shortcomings during installation work

When organizing such work, sometimes the mastersmake typical mistakes. Some of them are associated with a lack of understanding of sound insulation. This term is associated with the process of reducing the noise range at the moment when it passes through the barrier. This fact must be taken into account when constructing an insulating base. In this case, the sound insulation index of the walls will be the most effective. Sometimes intense noises arise due to the operation of such engineering systems as a water pump, an autonomous power plant. To protect yourself from such sounds, you need to make the placement of the greatest distance from the partition that separates this room from the living area. Some inexperienced craftsmen consider mineral wool-based sealing to be a strong insulator. Of course, this type of material copes well with its task. But to improve sound insulation performance, you need to combine this building material with a special device of acoustic saving devices. The design should be supplemented with a special fastener. Some believe that foam plastic is affordable and is the most effective means for enhancing the sound insulation properties of the partition. Polystyrene foam sheets are very dense. But despite this quality, they will not be a good material for soundproofing a room. Another point is that a quality material must necessarily have a well-ventilated structure. And polystyrene foam, as you know, does not have it. These are not all the typical mistakes that inexperienced builders make. An essential and important point in organizing these events will be the choice of a suitable foundation. Having given preference to the right option, you can make a structure that will please you for many years. Using auxiliary means to ensure a high-quality system, you can increase the absorption rates of air sound vibrations. And they do not linger in a hollow wall. Naturally, the choice of such bases will depend on the wishes of the owner. However, the joint use of several types of materials gives the best results in absorbing sound vibrations.