The interior door is always in the fieldvision, so its installation must be done without the slightest flaw, so that it does not remind you of itself every time it is opened or closed. How or with the help of hired workers, everyone must decide for themselves. However, it is necessary to have an idea of the progress of the process at least in order to control the work of the master. Interior doors should be a beautiful and harmonious addition to the interior.

Interior doors should be a beautiful and harmonious addition to the interior.

Types of doors and boxes for installation

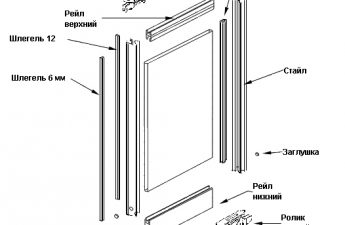

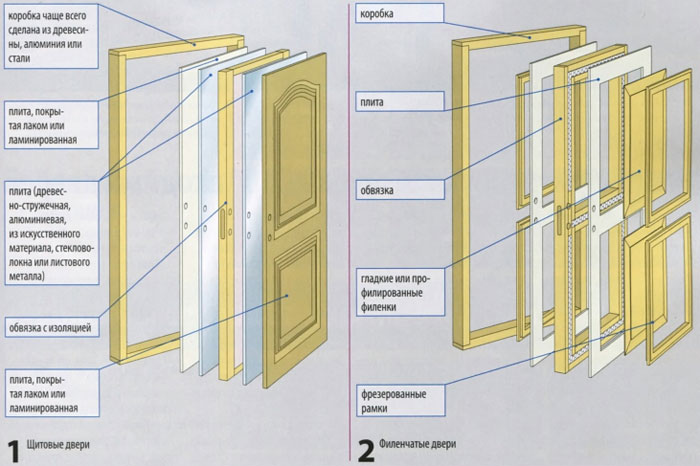

Before installing interior doors,you should make a choice. There are many door options on the market today, varying in material and design. From the point of view of technology, the most important material for installation is the one from which the door leaf, frame and additional elements are made. Types of interior doors by opening method. According to design, interior doors are distinguished:

Types of interior doors by opening method. According to design, interior doors are distinguished:

- made of solid wood;

- panel (frame) doors.

The frame of such a door is made of bars andis covered with sheets of fiberboard with subsequent finishing. In terms of filling, such doors can be hollow or filled with short length pieces of bars. The frame and additional elements can be made of solid wood or MDF with various variations of decorative finishing (paint coating, lamination or untreated solid wood). Different materials will dictate different technological methods of work during installation of the door leaf. Return to contents</a>

Basic fixing methods

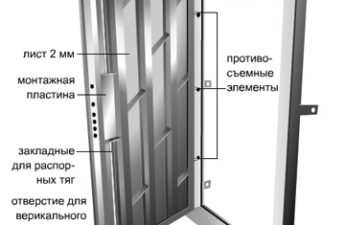

Classification of interior doors according to varioussigns. There are several practical methods for installing a modern interior door, each with its own advantages and disadvantages. The most reliable option for fastening the frame in the doorway is using dowel nails of sufficient length or anchors. The vertical bars are drilled through and rigidly connected to the wall with fasteners. The disadvantage of this method of fastening is that the fastening points are visible on the surface of the vertical posts. You can disguise the fastener heads by installing plastic decorative plugs of a suitable color. A more radical, but more expensive option for disguising the fasteners is to use a frame with a groove for installing the fasteners and an insert, which closes this groove after the work is completed. Less expensive, but less reliable will be through fastening of the door through the holes in the hinges and the mating part of the lock. Here, as in the previous case, rigid fastening to the wall is carried out. Due to the fact that there are actually only three attachment points, the door frame structure will withstand smaller loads without deformation. But here there is no need to hide the fasteners. They are camouflaged as standard hardware fasteners.

Classification of interior doors according to varioussigns. There are several practical methods for installing a modern interior door, each with its own advantages and disadvantages. The most reliable option for fastening the frame in the doorway is using dowel nails of sufficient length or anchors. The vertical bars are drilled through and rigidly connected to the wall with fasteners. The disadvantage of this method of fastening is that the fastening points are visible on the surface of the vertical posts. You can disguise the fastener heads by installing plastic decorative plugs of a suitable color. A more radical, but more expensive option for disguising the fasteners is to use a frame with a groove for installing the fasteners and an insert, which closes this groove after the work is completed. Less expensive, but less reliable will be through fastening of the door through the holes in the hinges and the mating part of the lock. Here, as in the previous case, rigid fastening to the wall is carried out. Due to the fact that there are actually only three attachment points, the door frame structure will withstand smaller loads without deformation. But here there is no need to hide the fasteners. They are camouflaged as standard hardware fasteners. Construction of panel and panel doors.And finally, the method that is the least labor-intensive in terms of time. In this case, the door frame is set in the opening in the required position and fixed with wooden pads. Then all the free space between the beams and the wall is filled with mounting foam. It should be understood that with this type of fastening, the entire load will be taken by a layer of hardened foam. And if you hang a heavy door, then over time it can loosen the jamb and even tear it out. Only light panel doors can be installed with mounting foam. Return to contents</a>

Construction of panel and panel doors.And finally, the method that is the least labor-intensive in terms of time. In this case, the door frame is set in the opening in the required position and fixed with wooden pads. Then all the free space between the beams and the wall is filled with mounting foam. It should be understood that with this type of fastening, the entire load will be taken by a layer of hardened foam. And if you hang a heavy door, then over time it can loosen the jamb and even tear it out. Only light panel doors can be installed with mounting foam. Return to contents</a>

List of tools and consumables required for work

To perform the installation, you will need a certain set of tools and consumables:

- hacksaw - for cutting box beams;

- electric drill;

- a hammer drill (it is necessary if the wall material is reinforced concrete, in all other cases you can usually get by with a drill);

- chisel, it will be required for inserting the hinges and door-latch;

- the building level, will help to independently check the correctness of the installation in the vertical plane;

- dowel-nails or anchor bolts;

- mounting foam.

Naturally, to perform installation work, in addition to everything listed above, you will need the following door kit parts: Methods of door fastening.

Methods of door fastening.

- door leaf;

- set of beams of the box;

- threshold, if necessary;

- additional elements to inscribe interior doors in the opening with a large wall thickness;

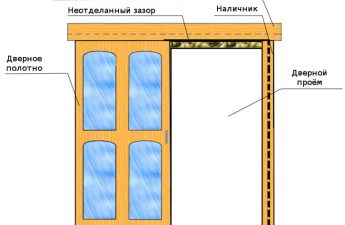

- it frames the installed interior door around the perimeter on the wall surface and closes the gap between the box and the opening.

Return to Contents</a>

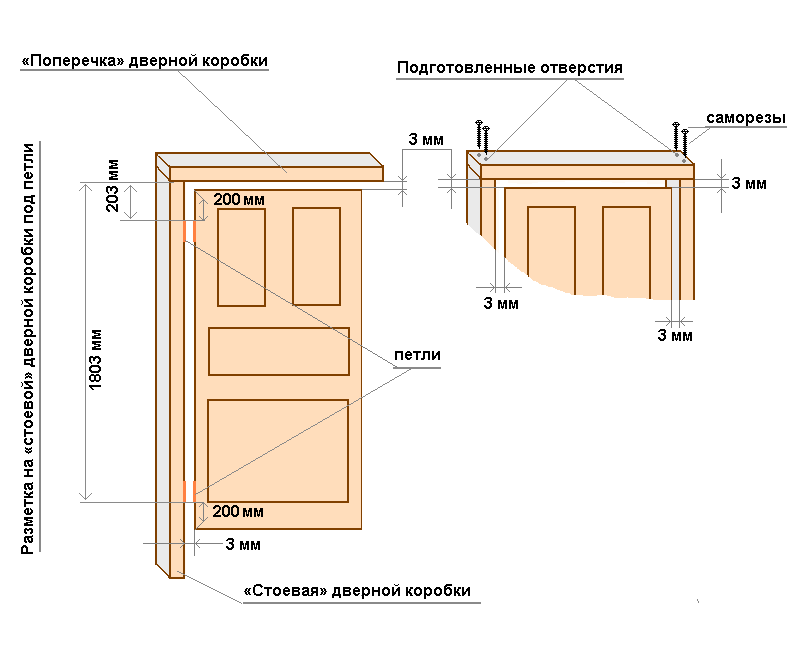

Assembling boxes: recommendations

Typically a set of beams that formbox, consists of two vertical posts and one horizontal crossbar. In some cases, they are supplemented by a threshold. Before , it is necessary to adjust the parts to the size of the door leaf and the opening where the installation will take place. Using a hacksaw with fine teeth, the vertical posts are cut to the desired size at an angle of 45 °. Marking the door frame and door for hinges.It should be noted that the cutting angle should be at the top of the beam on the side facing the door. The upper horizontal lintel is adjusted in a similar manner. It is not necessary to adjust the parts to each other at an angle of 45°. Basically, you can connect them at 90° with the upper lintel supported by vertical posts. This option will be somewhat simpler to implement than the previous one, although it will be inferior in aesthetic terms. If it is necessary to install a threshold, it is adjusted to the posts at a right angle. A very important point that cannot be overlooked is the accuracy of the fit. A gap of 3-5 mm should be left between the beams of the frame and the door leaf. This is necessary to compensate for possible changes in the size of the door due to fluctuations in air humidity. In the case of an exact fit, a jamming effect may occur, and then the interior door will have to be opened with a shoulder. Return to the table of contents</a>

Marking the door frame and door for hinges.It should be noted that the cutting angle should be at the top of the beam on the side facing the door. The upper horizontal lintel is adjusted in a similar manner. It is not necessary to adjust the parts to each other at an angle of 45°. Basically, you can connect them at 90° with the upper lintel supported by vertical posts. This option will be somewhat simpler to implement than the previous one, although it will be inferior in aesthetic terms. If it is necessary to install a threshold, it is adjusted to the posts at a right angle. A very important point that cannot be overlooked is the accuracy of the fit. A gap of 3-5 mm should be left between the beams of the frame and the door leaf. This is necessary to compensate for possible changes in the size of the door due to fluctuations in air humidity. In the case of an exact fit, a jamming effect may occur, and then the interior door will have to be opened with a shoulder. Return to the table of contents</a>

Furniture fittings: features

Scheme of cutting a handle into an interior door.While the frame is not installed in the opening, it is very convenient to cut in the hinges and locks. The door and frame are temporarily assembled on the floor of the room. The location of the hinges and the door handle-latch is marked with a pencil. Then all the parts are separated again and the full location of the fittings is drawn on them. The selection of excess material is a very important moment. The smoothness of the door, the presence of a creak and the period of trouble-free operation will depend on how well it is done. If the material of the door and jamb is wood, then a chisel will be quite enough to perform the work on fitting the fittings. The grooves for the hinges are selected in an elementary way: a cut is made along the outlined perimeter to the depth of the hinge installation. Then everything that is inside is simply cut off. It will be a little more difficult to cut in the lock. To facilitate the selection of a deep groove, you will need to use a drill here. The diameter of the drill installed in the chuck should be slightly less than the thickness of the fittings being cut in. In fact, the groove for the installed lock is drilled in the wood. All that remains is to align its walls with a chisel to perform a tight, distortion-free installation. If the cut is made not in wood, but in MDF, the requirements for the sharpness of the tool increase several times. This is due to the characteristics of the material itself. MDF, compared to wood, is a harder material, but at the same time much less durable. Excessive force applied when selecting grooves for hinges or a lock can simply split the workpieces. The best option in this case for cutting the fittings is to use a hand router. Specialized devices and templates will help to facilitate the work and increase the accuracy of the grooves on the end of the door and vertical posts. They can be purchased in advance or made independently from scrap materials. A router will also come in handy when working with wood. Return to contents</a>

Scheme of cutting a handle into an interior door.While the frame is not installed in the opening, it is very convenient to cut in the hinges and locks. The door and frame are temporarily assembled on the floor of the room. The location of the hinges and the door handle-latch is marked with a pencil. Then all the parts are separated again and the full location of the fittings is drawn on them. The selection of excess material is a very important moment. The smoothness of the door, the presence of a creak and the period of trouble-free operation will depend on how well it is done. If the material of the door and jamb is wood, then a chisel will be quite enough to perform the work on fitting the fittings. The grooves for the hinges are selected in an elementary way: a cut is made along the outlined perimeter to the depth of the hinge installation. Then everything that is inside is simply cut off. It will be a little more difficult to cut in the lock. To facilitate the selection of a deep groove, you will need to use a drill here. The diameter of the drill installed in the chuck should be slightly less than the thickness of the fittings being cut in. In fact, the groove for the installed lock is drilled in the wood. All that remains is to align its walls with a chisel to perform a tight, distortion-free installation. If the cut is made not in wood, but in MDF, the requirements for the sharpness of the tool increase several times. This is due to the characteristics of the material itself. MDF, compared to wood, is a harder material, but at the same time much less durable. Excessive force applied when selecting grooves for hinges or a lock can simply split the workpieces. The best option in this case for cutting the fittings is to use a hand router. Specialized devices and templates will help to facilitate the work and increase the accuracy of the grooves on the end of the door and vertical posts. They can be purchased in advance or made independently from scrap materials. A router will also come in handy when working with wood. Return to contents</a>

Box installation: highlights

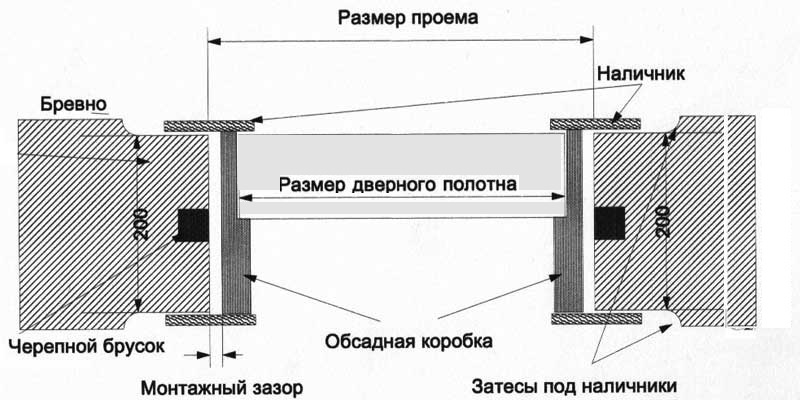

The scheme provides for the installation of a doordoor leaf into the door frame. The most reliable and durable way to install a door is to firmly secure the posts to the wall in the doorway using fasteners. First, the interior door and frame are assembled and installed in the doorway. Its position is checked with a level. Wooden spacers - wedges - are installed in the remaining free gaps. They simultaneously fix the door and prevent the posts from sagging when they are fastened. Then the door leaf is removed and holes are drilled for the fastening fittings. The frame material is drilled with a drill with a regular wood drill. The holes in the wall for the dowels must already be drilled either with a hammer drill or a drill with a concrete drill. In order not to knock down the set position, the wall can be drilled directly through the jamb. You just need to take a longer drill. After all the planned holes have been drilled, the fasteners are installed in them and securely fixed. When installing the fasteners, care must be taken not to move the jamb from its original position. To do this, periodically check the verticality of the position with a level. , using hidden rigid fastening with hangers for installing drywall. The hanger is bent in the form of a U-shaped bracket. The crossbar of this bracket is fastened with self-tapping screws to the vertical posts on the side of the doorway. The legs of the bracket are fixed with dowels on the surface of the bracket. The use of hangers allows you to refuse the use of wooden spacers, which somewhat simplifies the installation process. The gap left between the jamb and the wall during installation is carefully filled with mounting foam. When hardening, the mounting foam expands and can bend the beams of the frame. Therefore, if it is possible not to use the doorway for some time, it is best to play it safe and install spacers between the vertical posts. After the foam has completely hardened, its excess is cut off with a knife. The installation process is basically complete. Further work is related to the decorative design of the opening: installation of additional elements and door trims (casing). As you can see, it is not that difficult, the main thing is not to rush and perform all operations with maximum precision.

The scheme provides for the installation of a doordoor leaf into the door frame. The most reliable and durable way to install a door is to firmly secure the posts to the wall in the doorway using fasteners. First, the interior door and frame are assembled and installed in the doorway. Its position is checked with a level. Wooden spacers - wedges - are installed in the remaining free gaps. They simultaneously fix the door and prevent the posts from sagging when they are fastened. Then the door leaf is removed and holes are drilled for the fastening fittings. The frame material is drilled with a drill with a regular wood drill. The holes in the wall for the dowels must already be drilled either with a hammer drill or a drill with a concrete drill. In order not to knock down the set position, the wall can be drilled directly through the jamb. You just need to take a longer drill. After all the planned holes have been drilled, the fasteners are installed in them and securely fixed. When installing the fasteners, care must be taken not to move the jamb from its original position. To do this, periodically check the verticality of the position with a level. , using hidden rigid fastening with hangers for installing drywall. The hanger is bent in the form of a U-shaped bracket. The crossbar of this bracket is fastened with self-tapping screws to the vertical posts on the side of the doorway. The legs of the bracket are fixed with dowels on the surface of the bracket. The use of hangers allows you to refuse the use of wooden spacers, which somewhat simplifies the installation process. The gap left between the jamb and the wall during installation is carefully filled with mounting foam. When hardening, the mounting foam expands and can bend the beams of the frame. Therefore, if it is possible not to use the doorway for some time, it is best to play it safe and install spacers between the vertical posts. After the foam has completely hardened, its excess is cut off with a knife. The installation process is basically complete. Further work is related to the decorative design of the opening: installation of additional elements and door trims (casing). As you can see, it is not that difficult, the main thing is not to rush and perform all operations with maximum precision.