How to cover a wall with plasterboard is of interest to thosewho decided to cope with the repair in the house in a short time without significant labor costs and large financial resources. GKL levels surfaces well and serves as a good base for finishing coatings. By covering the walls with this material, you lose only in one thing - the area of the room, which will decrease somewhat after equipping the frame for the plasterboard. Plasterboard sheets have a fairly flexible structure, making them ideal for leveling walls.

Plasterboard sheets have a fairly flexible structure, making them ideal for leveling walls.

Construction of frame from profiles

Now about how to assemble the frame, on which the walls will be sheathed. To build it, you will need:

- UD-profiles (guides);

- CD-profiles (rack-mountable);

- straight suspension (U-shaped);

- single-level connections ("crabs");

- self-tapping screws with metal washers (3 x 9.5 mm);

- dowel-nails (6 x 40 mm).

Prepare:

- level;

- plumb bob;

- roulette;

- a piece of chalk;

- impact drill;

- Screwdriver;

- scissors for metal.

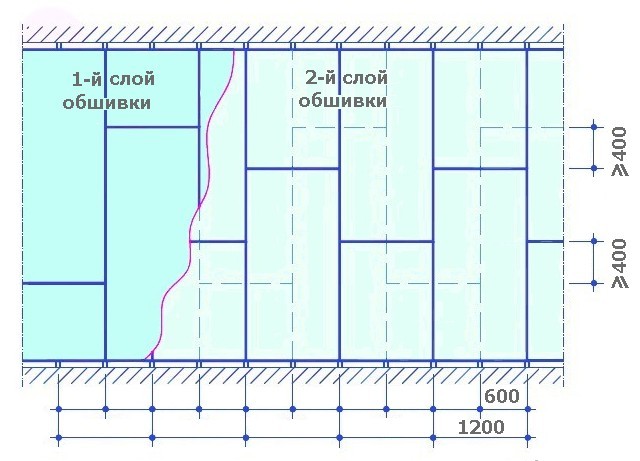

Installation of a frame for plasterboard.The frame assembly begins with the installation of guide profiles. Draw a line parallel to the wall on the ceiling. Use a plumb line to mark the floor. Attach the UD profiles to the floor and ceiling with dowel nails. The fasteners should be spaced 30 cm apart. Install the rack profiles in the guides. Their base should be directed towards the future sheathing. The distance between the centers of the CD profiles should be 60 cm. The rack profiles are attached to the guides with self-tapping screws for metal. The verticality of the strips is checked with a level. The plane of the base is almost ready, but it must be reinforced by attaching the CD profiles to the wall with U-shaped hangers. They are installed along the CD every ½ m. The first straight hanger from the bottom is attached to the surface 30 cm from the floor. The U-shaped hangers are connected to the wall with dowel nails, and to the racks - with self-tapping screws for metal. The hanger antennae protruding beyond the plane of the frame are bent back. Additional rigidity of the structure will be provided by installing crossbars made of rack profiles between the CD. They are pulled together with the verticals using “crabs”. The profiles should be installed along the perimeter of window and door openings, but when installing them, it should be taken into account that the joints of the plasterboard cannot be located on any line of the opening contour, since such an arrangement will lead to the formation of cracks in the plasterboard wall. The nearest joint of the plasterboard from the vertical or horizontal line of the window or door opening should be 40 cm away. You can use a grinder to cut the profile, but indoors it is still better to use metal scissors, especially since the thin metal of the profiles is cut very easily. Return to contents</a>

Installation of a frame for plasterboard.The frame assembly begins with the installation of guide profiles. Draw a line parallel to the wall on the ceiling. Use a plumb line to mark the floor. Attach the UD profiles to the floor and ceiling with dowel nails. The fasteners should be spaced 30 cm apart. Install the rack profiles in the guides. Their base should be directed towards the future sheathing. The distance between the centers of the CD profiles should be 60 cm. The rack profiles are attached to the guides with self-tapping screws for metal. The verticality of the strips is checked with a level. The plane of the base is almost ready, but it must be reinforced by attaching the CD profiles to the wall with U-shaped hangers. They are installed along the CD every ½ m. The first straight hanger from the bottom is attached to the surface 30 cm from the floor. The U-shaped hangers are connected to the wall with dowel nails, and to the racks - with self-tapping screws for metal. The hanger antennae protruding beyond the plane of the frame are bent back. Additional rigidity of the structure will be provided by installing crossbars made of rack profiles between the CD. They are pulled together with the verticals using “crabs”. The profiles should be installed along the perimeter of window and door openings, but when installing them, it should be taken into account that the joints of the plasterboard cannot be located on any line of the opening contour, since such an arrangement will lead to the formation of cracks in the plasterboard wall. The nearest joint of the plasterboard from the vertical or horizontal line of the window or door opening should be 40 cm away. You can use a grinder to cut the profile, but indoors it is still better to use metal scissors, especially since the thin metal of the profiles is cut very easily. Return to contents</a>

Installation of plasterboard panels

Scheme of a plasterboard box.After installing the frame, you should cover the wall with plasterboard. Standard plasterboard sheets fit perfectly on a properly installed lathing. And this material is very easy to cut. A construction knife is suitable for this. It makes a deep cut on the sheet. The knife should be guided by applying a ruler to the cutting line. After this, the plasterboard is broken and the cardboard is cut with a knife from the back side. After cutting the sheet, you need to process its edge with sandpaper. It should be slightly beveled so that the seams between the plasterboards are easier to putty after installation. In addition to a knife, sandpaper (or a stripping plane), you will need the following to install the plasterboard:

Scheme of a plasterboard box.After installing the frame, you should cover the wall with plasterboard. Standard plasterboard sheets fit perfectly on a properly installed lathing. And this material is very easy to cut. A construction knife is suitable for this. It makes a deep cut on the sheet. The knife should be guided by applying a ruler to the cutting line. After this, the plasterboard is broken and the cardboard is cut with a knife from the back side. After cutting the sheet, you need to process its edge with sandpaper. It should be slightly beveled so that the seams between the plasterboards are easier to putty after installation. In addition to a knife, sandpaper (or a stripping plane), you will need the following to install the plasterboard:

- self-tapping screws with countersunk heads 3 x 25 mm;

- long ruler;

- pencil.

After applying the plasterboard to the frame, screw in the screws.Along the perimeter of the sheet, they should be located at a distance of 15 cm from each other, and screws are screwed into the profiles in the center of the plasterboard every 25 cm. The distance from the edge of the plasterboard to the screws should not be less than 1 cm. In the corner parts of the panel, the fasteners are screwed in no closer than 5 cm from the corner. The screws are screwed in perpendicular to the profile, and the heads of the screws should be slightly recessed into the plasterboard, but you should not break through the outer layer of cardboard with them. If the screw is screwed in incorrectly (fell into the void, etc.), it should be removed and screwed in, stepping back 5 cm from the previous place. Scheme of fastening plasterboard with glue About howIt has already been written about how to arrange gypsum boards when covering openings. Now we should talk about installing panels when 2 or more sheets are installed in a vertical row. In this case, the horizontal joints in adjacent rows of gypsum boards should not coincide. Sheathe the wall so that these seams are as far apart as possible. It should be added that a gap of 2-3 mm must be maintained between gypsum boards. In openings, the cladding can be attached to the lathing or to adhesive mixtures. After completing the wall sheathing, the gypsum board must be puttied. First, all joints, recesses, places of tears and fastener installations are treated with a primer. Serpyanka is glued along the seams. Everything listed above is puttied. As soon as the putty dries, the entire surface of the gypsum board is primed and another layer of putty is applied, which is cleaned with sandpaper after hardening. Return to contents</a>

Scheme of fastening plasterboard with glue About howIt has already been written about how to arrange gypsum boards when covering openings. Now we should talk about installing panels when 2 or more sheets are installed in a vertical row. In this case, the horizontal joints in adjacent rows of gypsum boards should not coincide. Sheathe the wall so that these seams are as far apart as possible. It should be added that a gap of 2-3 mm must be maintained between gypsum boards. In openings, the cladding can be attached to the lathing or to adhesive mixtures. After completing the wall sheathing, the gypsum board must be puttied. First, all joints, recesses, places of tears and fastener installations are treated with a primer. Serpyanka is glued along the seams. Everything listed above is puttied. As soon as the putty dries, the entire surface of the gypsum board is primed and another layer of putty is applied, which is cleaned with sandpaper after hardening. Return to contents</a>

Construction of plasterboard partitions

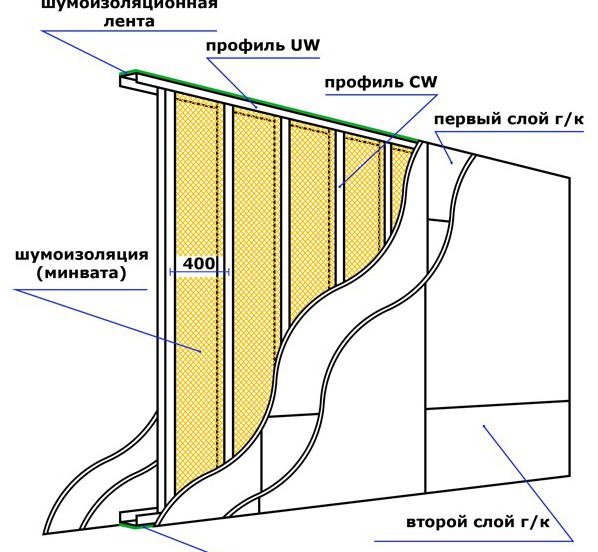

A separate section should be devoted to constructionpartitions, in which gypsum plasterboard is almost the most irreplaceable material. Partitions made of gypsum plasterboard are erected when it is necessary to divide a room with a light wall that does not exert a large load on the ceiling. Scheme of the device of a partition from plasterboard withsound insulation. To build walls of this kind, guides, rack profiles and wooden bars are used, which will help to strengthen the doorway. In addition to the usual set for installing drywall, you will need:

Scheme of the device of a partition from plasterboard withsound insulation. To build walls of this kind, guides, rack profiles and wooden bars are used, which will help to strengthen the doorway. In addition to the usual set for installing drywall, you will need:

- polypropylene tape;

- sound insulator (mineral wool).

Draw a line of the wall on the floor.Using a plumb line, mark the ceiling. Attach the guides to the surfaces with dowel nails. Their back sides should be covered with tape to improve sound insulation. Install the guides near the walls and secure them. UD profiles should also be installed at the doorway. Their bases should be directed towards the door frame. Check their verticality with a level and insert wooden blocks from the floor to the ceiling inside the profiles near the opening. Tighten them with guide screws. Now insert the rack profiles into the UD and secure them with screws. You can insert electrical wiring and communications cables into the frame. Strengthen the structure with horizontal crossbars and cover one side of the frame with plasterboard. It remains to lay mineral wool and completely sheathe the partition.