Sometimes a very unpleasant problem during repairsrooms, bathrooms, kitchens become pipes, which, although they are located in less noticeable places, still stick out unsightly, spoiling the overall appearance of the room. In such cases, the question arises of how to hide them, conceal them or give them a more or less normal appearance. Before covering the pipes with plasterboard, you need to know a few rules. The appearance of a room is sometimes spoiled by pipes,which can be covered with plasterboard. In the toilet, the need to disguise the waste pipe most often arises. Its inappropriate appearance can ruin even a perfectly done renovation and design of this room. By covering it with facing material, this problem can be solved. Before work, it is necessary to prepare the material and tools:

The appearance of a room is sometimes spoiled by pipes,which can be covered with plasterboard. In the toilet, the need to disguise the waste pipe most often arises. Its inappropriate appearance can ruin even a perfectly done renovation and design of this room. By covering it with facing material, this problem can be solved. Before work, it is necessary to prepare the material and tools:

- metal profiles, rack and rail, angular profile;

- GCR sheets, better moisture-resistant green;

- dowels, screws, screws, stationery knife;

- cushioning tape;

- level, plumb bob;

- pencil, ruler;

- nazhdachka, electric drill;

- putty, primer, spatula, roller, finishing putty.

Characteristics of the material and works

The structure of a plasterboard sheet.Plasterboard sheets have a multilayer structure, they consist of gypsum, which is decorated with hard paper. Standard sheets have a size of 2.5 x 1.2 m. For example, to cover a waste pipe, you will need one such sheet. The material is environmentally friendly and does not emit harmful substances when heated, in addition, it is available and easy to use. There is an opinion that it is afraid of moisture. Yes, this is true, but this problem has been solved long ago: there is moisture-resistant plasterboard, it has a greenish color. To cover a pipe with plasterboard, it alone will not be enough, the material must be held on the frame. In this way, a plasterboard box is formed, the frame of which has vertical and horizontal elements. The former alternate with a distance of less than 60 cm. The final stage of the frame is to cover its profiles with plasterboard sheets. In this case, simple self-tapping screws are used, the heads of which must be sunk into the material. Such works do not require special qualifications and professional skills, it is enough to know how to use ordinary tools, the list of which is given below. It is very good when the master has skills in working with the material, for example, creating partitions or other plasterboard structures. Return to the table of contents</a>

The structure of a plasterboard sheet.Plasterboard sheets have a multilayer structure, they consist of gypsum, which is decorated with hard paper. Standard sheets have a size of 2.5 x 1.2 m. For example, to cover a waste pipe, you will need one such sheet. The material is environmentally friendly and does not emit harmful substances when heated, in addition, it is available and easy to use. There is an opinion that it is afraid of moisture. Yes, this is true, but this problem has been solved long ago: there is moisture-resistant plasterboard, it has a greenish color. To cover a pipe with plasterboard, it alone will not be enough, the material must be held on the frame. In this way, a plasterboard box is formed, the frame of which has vertical and horizontal elements. The former alternate with a distance of less than 60 cm. The final stage of the frame is to cover its profiles with plasterboard sheets. In this case, simple self-tapping screws are used, the heads of which must be sunk into the material. Such works do not require special qualifications and professional skills, it is enough to know how to use ordinary tools, the list of which is given below. It is very good when the master has skills in working with the material, for example, creating partitions or other plasterboard structures. Return to the table of contents</a>

Pipe pre-treatment

The first stage in all construction and repairwork is to prepare the work surface. So, having decided not to neglect the ugly appearance of the pipes, it is necessary to design and pack them in a beautiful lining. In addition to a beautiful appearance, this will also provide some protection for the sewer system, preserve its functionality, since their periodic repair depends on the condition of the pipes. Preparation for lining the pipe with plasterboard consists of its conservation, that is, removing rust, primer from it, and it is also necessary to process the joints. It is recommended to replace dilapidated areas, if possible. Work should be started from below, drawing on the floor the contours of the box that will stand there in the future. After taking the measurements of the pipes on the floor, it is necessarydraw the contours of the box. This is done in the following way. Take a square, try it on to the left of the wall from the pipe, draw a line along the floor plane, then repeat the operation, move the square to the right. Draw the boundaries in the shape of the letter G or P. If the box is planned to be tiled, then verify the parameters according to the size of its square or rectangle. Next, cut parts from the profile, which serves as a guide, measure their length according to the contours previously marked on the floor. Fix them with dowels along the drawn lines. Then take a CD profile, vertical frame posts will be cut from it, cut it to the height of the toilet room. It will be a template for the place under the upper guide. You should mark the location of the U-shaped contour from above the wall. Insert a template post into the lower guide, align it with the level, mark a point on the ceiling near the wall to the left of the pipe, do the same on the right.

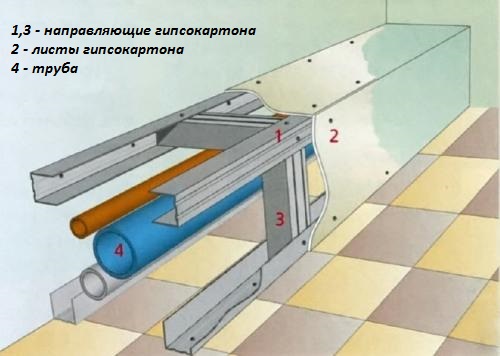

After taking the measurements of the pipes on the floor, it is necessarydraw the contours of the box. This is done in the following way. Take a square, try it on to the left of the wall from the pipe, draw a line along the floor plane, then repeat the operation, move the square to the right. Draw the boundaries in the shape of the letter G or P. If the box is planned to be tiled, then verify the parameters according to the size of its square or rectangle. Next, cut parts from the profile, which serves as a guide, measure their length according to the contours previously marked on the floor. Fix them with dowels along the drawn lines. Then take a CD profile, vertical frame posts will be cut from it, cut it to the height of the toilet room. It will be a template for the place under the upper guide. You should mark the location of the U-shaped contour from above the wall. Insert a template post into the lower guide, align it with the level, mark a point on the ceiling near the wall to the left of the pipe, do the same on the right. Guide profiles for plasterboard.Two lines are drawn on the ceiling perpendicular to the wall, the dimensions of the U-shaped contour are transferred to it. Three sections are made from the profile, they are attached to it with dowels. Then three more sections are cut from the CD profile, they will act as racks. They are inserted into the guides from above and below, the profile is formed. After this, plasterboard sheathing and its cladding are made. The racks from the CD profile must be fixed not with simple self-tapping screws, but with special - "bugs". It is recommended to strengthen the structure, to make it integral. For this, transverse elements are fixed inside and outside, they are made from the remains of the profile, they are also attached with "bugs". Return to the table of contents</a>

Guide profiles for plasterboard.Two lines are drawn on the ceiling perpendicular to the wall, the dimensions of the U-shaped contour are transferred to it. Three sections are made from the profile, they are attached to it with dowels. Then three more sections are cut from the CD profile, they will act as racks. They are inserted into the guides from above and below, the profile is formed. After this, plasterboard sheathing and its cladding are made. The racks from the CD profile must be fixed not with simple self-tapping screws, but with special - "bugs". It is recommended to strengthen the structure, to make it integral. For this, transverse elements are fixed inside and outside, they are made from the remains of the profile, they are also attached with "bugs". Return to the table of contents</a>

Immediate sheathing: recommendations

Before you start sheathing, you need toCut out blanks and templates from the material; they must match the dimensions of the frame. Three strips must be formed from the sheet of material with parameters for the frame. The first strip is marked on the sheet. A groove is cut from the front side along the markings with a wallpaper cutting knife. The sheet is placed vertically and broken along the cut part. The cut piece is held in the air and the material layer is trimmed from below, thus separating the first blank. The second and third are made in the same way, after which these parts are applied to the frame and fixed. Scheme of covering pipes with plasterboard.The most reliable fastening is conventional self-tapping screws for metal. After the work on fixing the frame and covering it with material, finishing work follows. It is necessary to take into account that the pipe must be accessible at any time for repair or checking its serviceability, therefore, opposite the removable fitting part, a window must be made through which it will be possible to get to this section if necessary. As you can see, the work is not at all difficult. The main stages are as follows:

Scheme of covering pipes with plasterboard.The most reliable fastening is conventional self-tapping screws for metal. After the work on fixing the frame and covering it with material, finishing work follows. It is necessary to take into account that the pipe must be accessible at any time for repair or checking its serviceability, therefore, opposite the removable fitting part, a window must be made through which it will be possible to get to this section if necessary. As you can see, the work is not at all difficult. The main stages are as follows:

- surface preparation of pipes, material;

- the product of the skeleton; where the profile is connected to the working surface, it must be glued with a shock-absorbing tape;

- plating it with plasterboard, the sheets are easily cut, their edges need to be processed, cleaned;

- if batteries and similar structures are lined, several holes are made for heat exchange;

- processing of the box.

The corners are reinforced with metal corners, the joints are sealed with putty. Then the structure is sanded and primed. Good luck!</ ul>