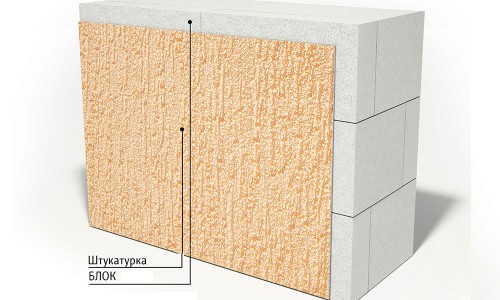

from aerated concrete should be carried out only withtaking into account all the features of this building material. Incorrect finishing can disrupt the microcirculation of aerated concrete walls and thereby significantly reduce the quality of construction work. Therefore, before you begin finishing a house made of aerated concrete blocks, you should find out all the necessary information on how to plaster walls made of aerated concrete. The simplest scheme for plastering a wall made of aerated concrete.

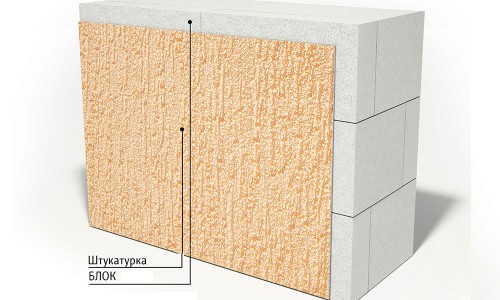

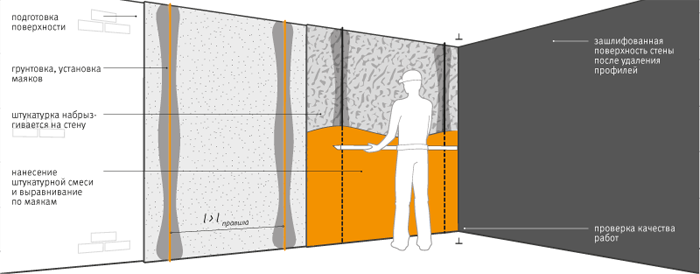

The simplest scheme for plastering a wall made of aerated concrete.

Rules of work

is a rather complex task that requires strict adherence to all the basic rules, namely:

To finish the walls of aerated concrete should be used only specially designed for this composition.

Do not hurry too much with the plaster of the house. The building, constructed of aerated concrete, has high strength and therefore does not need to finish the walls for several years.

When plastering a house from gas silicate blocks, first the interior walls are trimmed and only after that they start to finish the exterior.

Exterior finishing works must be carried out only at an air temperature of + 8 ° C to + 30 ° C.

It is necessary to strictly adhere to the correct sequence of applying finishing layers on the outer walls of the house.

In the process of plastering the walls,use only high-quality glass mesh. When fastening the nets, it is very important to adhere to the right technology, which prohibits them to be applied to the dry surface of the aerated concrete wall. Before fixing, moisten the wall with water and try to slightly press it into the finishing layer.

If necessary, it is necessary to provide a new plaster coating with reliable protection against various atmospheric precipitations.

Return to Contents</a>

Features of materials for plaster of aerated concrete

When choosing special plaster mixes intended specifically for finishing aerated concrete walls, you should focus on the following indicators: The adhesion of the plaster should be about 0.5 MPa;It is recommended to use compositions that are prepared in a mixture to water ratio of 30:8; the plaster should be applied in a layer of at least 2 mm, and at most 8-15 mm; one bag of plaster weighing 30 kg should be enough for 8 m² with a layer thickness of 2 mm.

The adhesion of the plaster should be about 0.5 MPa;It is recommended to use compositions that are prepared in a mixture to water ratio of 30:8; the plaster should be applied in a layer of at least 2 mm, and at most 8-15 mm; one bag of plaster weighing 30 kg should be enough for 8 m² with a layer thickness of 2 mm.

Adhesion of the plaster composition or, more simply,quality of adhesion of the mixture to the surface to be treated. Normally, adhesion should be about 0.5 megapascals (MPa). In some situations, this indicator is indicated in other values, but they can be easily transferred to MPa, using the calculated materials for this.

Equally important are the proportions of the preparation of the plaster mixture. It is recommended to choose the formulations that are prepared in the proportion of 30 kg of the mixture per 8 liters of water.

The largest and smallest layer of plaster, whichcan be applied to the surface of a gas-concrete wall. High quality plaster should be laid on the wall with both a very thin and very thick layer. The minimum thickness of this layer should not be more than 2 mm, and the maximum thickness from 8 to 15 mm. However, it is impossible to immediately plaster the wall with a very thick layer. This plaster coating is better done in several ways.

The useful life of the solution. For self-plastering the walls, mixes that are best suited for use after 3-4 hours are best suited. This will allow you to perform the finishing work at a calm pace and without unnecessary haste.

Versatility plaster mixture. Well, if one composition can be used both for finishing the outer walls of the house from aerated concrete, and for interior decoration works.

Optimum consumption of the finishing mixture. The most suitable is the consumption of the working mixture, when one bag of plaster composition weighing 30 kg is enough for plastering 8 m² of the wall surface with a layer thickness of 2 mm.

Of course, the value of the composition, that is, the ratio of its price and quality, is also of great importance.

Return to Contents</a>

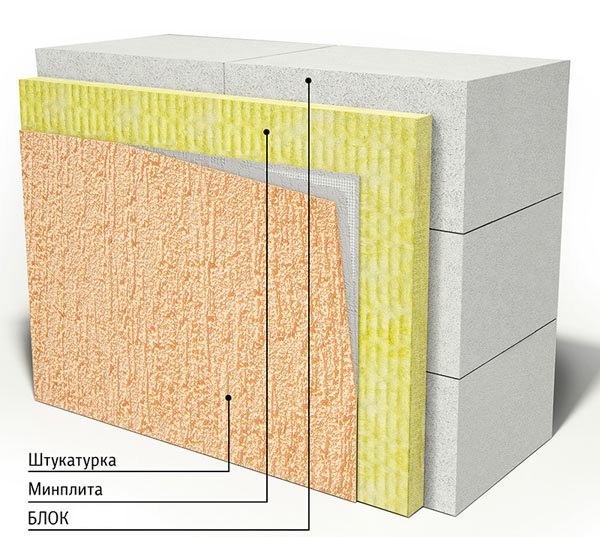

Plaster of internal walls

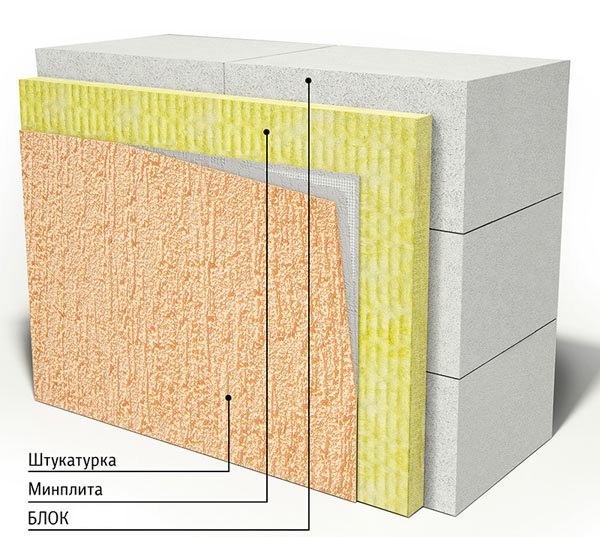

Scheme of insulation and plastering of the externalwalls. Finishing of a house built from aerated concrete blocks should begin with plastering the inner surface of the walls. This is explained by the fact that according to the factory technology, the humidity of finished aerated concrete blocks is 30%. However, for high-quality exterior finishing, the optimal humidity of such blocks should be 15%. Therefore, before starting to plaster the outer walls of the house, you must first complete the interior finishing of the rooms. During this period of time, excess moisture will come out through the outer surface of the wall and evaporate. Plastering of walls made of aerated concrete blocks inside the house should be carried out using the same technology that is used in conventional plastering work. The main difference in interior finishing is the use of special vapor-permeable compounds. These finishing works are carried out in the following sequence:

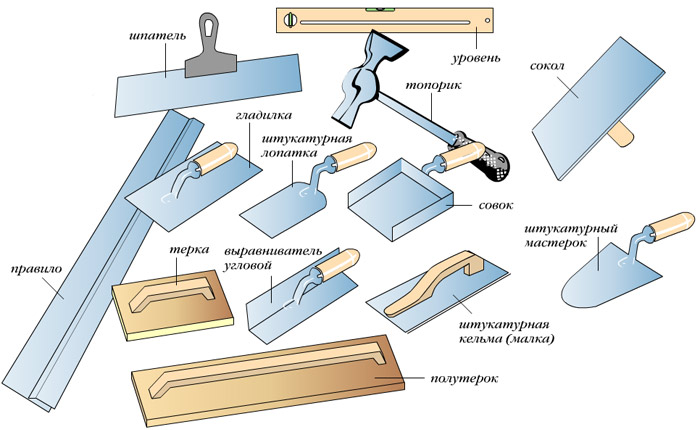

Scheme of insulation and plastering of the externalwalls. Finishing of a house built from aerated concrete blocks should begin with plastering the inner surface of the walls. This is explained by the fact that according to the factory technology, the humidity of finished aerated concrete blocks is 30%. However, for high-quality exterior finishing, the optimal humidity of such blocks should be 15%. Therefore, before starting to plaster the outer walls of the house, you must first complete the interior finishing of the rooms. During this period of time, excess moisture will come out through the outer surface of the wall and evaporate. Plastering of walls made of aerated concrete blocks inside the house should be carried out using the same technology that is used in conventional plastering work. The main difference in interior finishing is the use of special vapor-permeable compounds. These finishing works are carried out in the following sequence: List of tools for plastering walls.

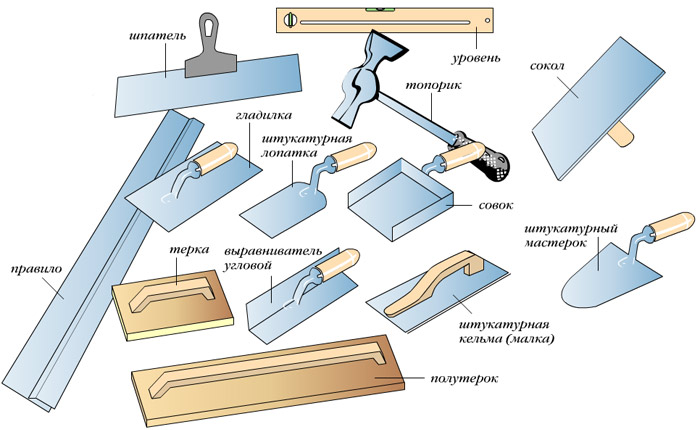

List of tools for plastering walls.

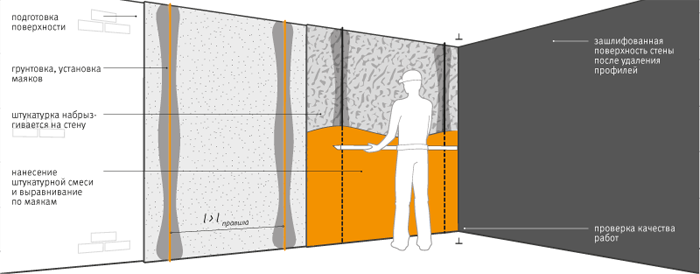

To begin with, a preparatorystage, which consists in thorough cleaning and subsequent priming of walls. For today in the building market there is a huge choice of various priming means which need to be selected for different premises separately depending on the purpose of the latter. For example, there are special primers for the bath, kitchen, living rooms and various unheated rooms.

The next stage is the installation of specialBeacons, which are long profiles of different thicknesses. They are installed in a vertical position and parallel to each other. To the surface of the wall beacons can be attached with a putty. Between beacons it is necessary to leave the distance, which is planned to be plastered in one working day. For one shift, as a rule, it is enough to install 3 or 4 beacons. After installation, it is necessary to carry out a check with a level to avoid unevenness.

Now you need to manually or with the help ofspecial stucco machine sketch on the wall of the fur coat. The plaster layer should be about 4 mm. But if there are any irregularities on the surface, then in some parts of the wall a layer of the plaster mixture up to 6 mm is allowed. Do not immediately put on a too thick layer of plaster, as this greatly increases the possibility of collapse of the composition. To proceed to the plaster of gas silicate blocks follows from the bottom of the wall, gradually rising to the ceiling. Further, using the rule, it is necessary to stretch the layer of plaster composition from the bottom up, while leaning on the beacons. Work must be very carefully, in no case avoiding the peeling of the plaster. Any voids should be immediately closed. The plaster layer should be compacted to 2 mm.

When the layer of plaster dries a little, you canproceed with its alignment. To do this, use a large metal spatula with smooth even edges. The alignment technology is as follows: smooth arc-shaped movements should carefully level a slightly hardened layer of plaster, until the surface becomes perfectly even. Now you need to carefully remove the lighthouses and carefully repair the remaining defects after them. In some cases, the beacons are not removed, but left in the wall. Also, to obtain a more durable and reliable coating, special reinforcing meshes for interior work can be used.

Return to Contents</a>

Plastering of external walls with own hands

Next, when the interior decoration of the house is madegas silicate blocks is completely finished, you can start plastering the walls of aerated concrete from the outside. When plastering the outer surface of the walls, three layers of plaster composition should be applied, and special reinforcing glass mesh should be used. Scheme of plastering of internal aerated concrete wallon beacons. It is important to remember that in this case the plaster should be applied in a thin layer of 4 to 10 mm. However, if during the construction of the house there were sufficiently wide seams left between the aerated concrete blocks, it will be more reliable to use a thick layer. It is also important to note that the plaster for external finishing of aerated concrete must necessarily have good vapor permeability. Necessary materials and tools:

Scheme of plastering of internal aerated concrete wallon beacons. It is important to remember that in this case the plaster should be applied in a thin layer of 4 to 10 mm. However, if during the construction of the house there were sufficiently wide seams left between the aerated concrete blocks, it will be more reliable to use a thick layer. It is also important to note that the plaster for external finishing of aerated concrete must necessarily have good vapor permeability. Necessary materials and tools:

- building beacons;

- trowel;

- rule;

- plaster mixture;

- level;

- thread;

- reinforcing mesh;

- priming emulsion;

- platen for primer.

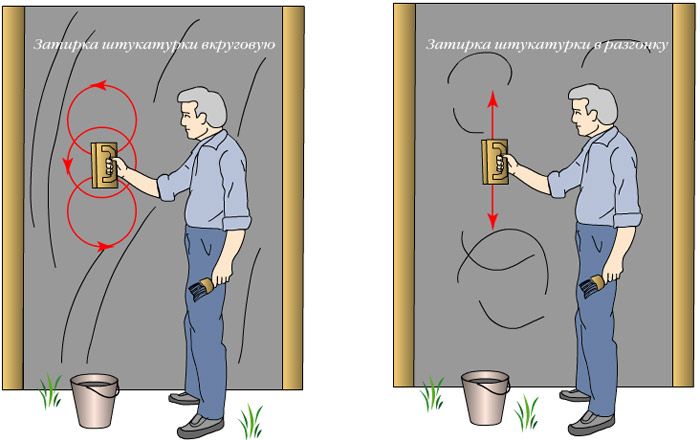

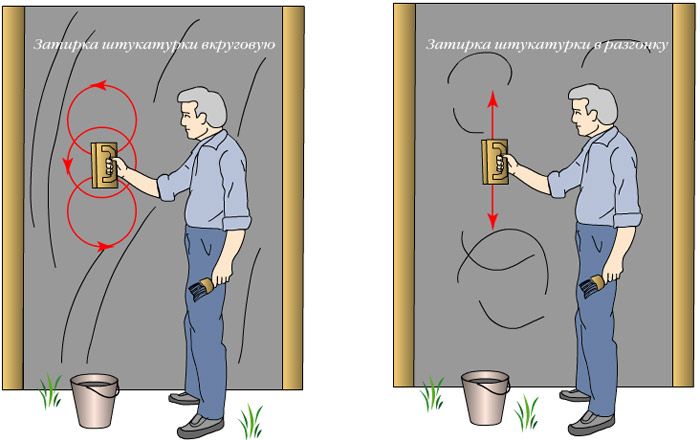

Plastering of walls made of aerated concrete blocks from the outside of the house is carried out as follows: Schemes for grouting plaster.

Schemes for grouting plaster.

First, using a spatula, acrylic or any other special primer is applied to the surface of the aerated concrete wall. In this case, the data layer of the primer should not be more than 2 mm.

Next, a layer of a plaster mixture with a thickness of about 5 mm is applied to the wall, on which reinforcing glass mesh is subsequently fixed.

The nets should be lapped with each other by 5 cm. At the corners of the building, special scarfs should be applied.

Then use a spatula to drown the mesh in the plaster layer and carefully align it.

Now it is necessary to wait about a week, so that the layer of the plaster composition is thoroughly dried.

In conclusion of the exterior finishing of the house from gas-silicate blocks its walls must be covered with a special coloring composition. The color can be chosen any at will of the owner.

The plaster coating made according to this technology will not only have a beautiful appearance, but also have the necessary strength and reliability. Have a successful renovation!

Comments

comments

The simplest scheme for plastering a wall made of aerated concrete.

The simplest scheme for plastering a wall made of aerated concrete. The adhesion of the plaster should be about 0.5 MPa;It is recommended to use compositions that are prepared in a mixture to water ratio of 30:8; the plaster should be applied in a layer of at least 2 mm, and at most 8-15 mm; one bag of plaster weighing 30 kg should be enough for 8 m² with a layer thickness of 2 mm.

The adhesion of the plaster should be about 0.5 MPa;It is recommended to use compositions that are prepared in a mixture to water ratio of 30:8; the plaster should be applied in a layer of at least 2 mm, and at most 8-15 mm; one bag of plaster weighing 30 kg should be enough for 8 m² with a layer thickness of 2 mm. Scheme of insulation and plastering of the externalwalls. Finishing of a house built from aerated concrete blocks should begin with plastering the inner surface of the walls. This is explained by the fact that according to the factory technology, the humidity of finished aerated concrete blocks is 30%. However, for high-quality exterior finishing, the optimal humidity of such blocks should be 15%. Therefore, before starting to plaster the outer walls of the house, you must first complete the interior finishing of the rooms. During this period of time, excess moisture will come out through the outer surface of the wall and evaporate. Plastering of walls made of aerated concrete blocks inside the house should be carried out using the same technology that is used in conventional plastering work. The main difference in interior finishing is the use of special vapor-permeable compounds. These finishing works are carried out in the following sequence:

Scheme of insulation and plastering of the externalwalls. Finishing of a house built from aerated concrete blocks should begin with plastering the inner surface of the walls. This is explained by the fact that according to the factory technology, the humidity of finished aerated concrete blocks is 30%. However, for high-quality exterior finishing, the optimal humidity of such blocks should be 15%. Therefore, before starting to plaster the outer walls of the house, you must first complete the interior finishing of the rooms. During this period of time, excess moisture will come out through the outer surface of the wall and evaporate. Plastering of walls made of aerated concrete blocks inside the house should be carried out using the same technology that is used in conventional plastering work. The main difference in interior finishing is the use of special vapor-permeable compounds. These finishing works are carried out in the following sequence: List of tools for plastering walls.

List of tools for plastering walls. Scheme of plastering of internal aerated concrete wallon beacons. It is important to remember that in this case the plaster should be applied in a thin layer of 4 to 10 mm. However, if during the construction of the house there were sufficiently wide seams left between the aerated concrete blocks, it will be more reliable to use a thick layer. It is also important to note that the plaster for external finishing of aerated concrete must necessarily have good vapor permeability. Necessary materials and tools:

Scheme of plastering of internal aerated concrete wallon beacons. It is important to remember that in this case the plaster should be applied in a thin layer of 4 to 10 mm. However, if during the construction of the house there were sufficiently wide seams left between the aerated concrete blocks, it will be more reliable to use a thick layer. It is also important to note that the plaster for external finishing of aerated concrete must necessarily have good vapor permeability. Necessary materials and tools: Schemes for grouting plaster.

Schemes for grouting plaster.