Some time ago, slatted ceilings wereinterior detail exclusively of public premises. They could be found in shopping centers, entertainment establishments, lobbies of administrative buildings. And only recently this type of ceiling covering began to gain popularity among craftsmen who install slatted ceilings with their own hands. But even in these cases, most often the area of application of slatted ceilings is limited to the bathroom. Aluminum slatted ceiling is suitable for installationin any room. The attractiveness of a ceiling covering that is not subject to rotting and corrosion in such a place is easy to explain: it does not promote the proliferation of harmful microflora and is not damaged by it, and can withstand treatment with any detergents and disinfectants. Installing a slatted ceiling is relatively inexpensive and quite affordable for a home craftsman. Another obvious advantage is that it is not necessary to level the surface of the rough ceiling, since the suspension system and smooth, even strips of covering allow you to create an ideal ceiling. And the ability to place spotlights in it, the convenience of performing multi-level covering, and the high decorativeness of some types of covering panels of the slatted ceiling make it increasingly attractive for decorating living spaces.

Aluminum slatted ceiling is suitable for installationin any room. The attractiveness of a ceiling covering that is not subject to rotting and corrosion in such a place is easy to explain: it does not promote the proliferation of harmful microflora and is not damaged by it, and can withstand treatment with any detergents and disinfectants. Installing a slatted ceiling is relatively inexpensive and quite affordable for a home craftsman. Another obvious advantage is that it is not necessary to level the surface of the rough ceiling, since the suspension system and smooth, even strips of covering allow you to create an ideal ceiling. And the ability to place spotlights in it, the convenience of performing multi-level covering, and the high decorativeness of some types of covering panels of the slatted ceiling make it increasingly attractive for decorating living spaces.

Tools, calculation of quantity of materials

Among the tools and materials required for assembling a slatted ceiling with your own hands, the following can be named:

- elements of the suspended lath ceiling (profile, stringer, pendants, panels);

- perforator, screwdriver;

- construction level;

- tape measure, ruler;

- scissors for metal, pliers or pliers;

- Fastening elements (dowels, screws).

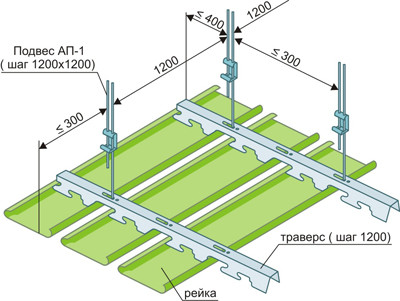

The calculation of the material can be made based on the results of measuring the perimeter of the room and determining its area: Scheme of suspension of a slatted ceiling.

Scheme of suspension of a slatted ceiling.

When it is planned to install a ceiling in severallevels, you will need to separately calculate the amount of materials for each of them. When choosing an open ceiling for installation (with a gap between the slats of up to 15 mm), you will need to take care of calculating and purchasing a special profile - the layout between the panels. Return to the table of contents</a>

Mounting technology for suspended ceilings

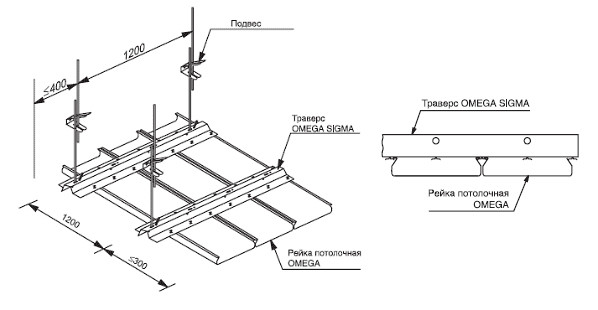

Figure 1. Construction of a slatted ceiling.In order for the surface of the future covering to be horizontal and even, the first step before installation should be marking the horizontal. A hydraulic level is traditionally used for marking it, but at home it can be replaced with a construction level. Applying the tool to the wall and monitoring the placement of the air bubble in the flask exactly in the middle, marked with a special line, you need to apply several marks on the walls along the entire length. After that, they are connected by drawing the attachment point along the ruler. The distance to the suspended covering can be at least 5 cm, if it is not planned to place communications hidden in the ceiling. In other cases, the distance is determined individually depending on the needs. For marking for stringers, you need to take into account the specified step of the parts and monitor the parallelism of the lines in relation to each other. The perpendicularity of the stringers to the side walls and panels is measured with a square. After applying the markings, you can proceed to the installation of the slatted ceiling. Return to the table of contents</a>Installation of load-bearing parts Load-bearing parts include profiles, hangers and stringers.

Figure 1. Construction of a slatted ceiling.In order for the surface of the future covering to be horizontal and even, the first step before installation should be marking the horizontal. A hydraulic level is traditionally used for marking it, but at home it can be replaced with a construction level. Applying the tool to the wall and monitoring the placement of the air bubble in the flask exactly in the middle, marked with a special line, you need to apply several marks on the walls along the entire length. After that, they are connected by drawing the attachment point along the ruler. The distance to the suspended covering can be at least 5 cm, if it is not planned to place communications hidden in the ceiling. In other cases, the distance is determined individually depending on the needs. For marking for stringers, you need to take into account the specified step of the parts and monitor the parallelism of the lines in relation to each other. The perpendicularity of the stringers to the side walls and panels is measured with a square. After applying the markings, you can proceed to the installation of the slatted ceiling. Return to the table of contents</a>Installation of load-bearing parts Load-bearing parts include profiles, hangers and stringers. Elements of the slatted ceiling design.

Elements of the slatted ceiling design.

It is advisable to check the installed ceiling frame once again for horizontality and then proceed to installing the ceiling rail (Fig. 1). Return to contents</a>How to install panels on a frame Before starting installation, measure a strip of the required length, taking into account gaps of 3 mm between the wall and the part. Tools for installing slatted ceilings.

Tools for installing slatted ceilings.

In the event that the total width of the panelsis longer than the width of the room, one of the last panels should be cut to the width. To do this, make a cut along the entire length of the panel using a ruler or a metal knife. Bending it, break off the excess. If the length of the panel is large, you can make cuts with scissors on the part to be removed up to the drawn line and break off individual pieces. It is recommended to mount such a cut piece not last, but the penultimate one. Return to contents</a>

Useful tips for the master

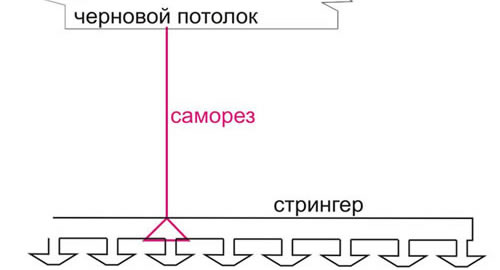

When the length of the room exceeds the standard lengthpanels, they will have to be extended. There are special parts for this - intermediate inserts. The need to purchase them is determined during measurements and calculations before the assembly of the slatted ceiling begins. The principle of stringer installation.It is best to place the slatted panels in a direction perpendicular to the wall with windows. But if you are placing a window in the end wall of a long narrow room, you should prefer a direction perpendicular to the long walls. This will help to visually change the proportions of the room to better ones. When installing spotlights, you will need to cut holes in the panel. To do this, draw a circle of the desired diameter and make a series of cuts from the center, bending them to the back of the ceiling. In this case, you should make cuts more often so that the bent elements are as narrow as possible. When installing, remember that scratches on the front side of the panel can deprive the new ceiling of some of its attractiveness. When choosing the type of panel coating, it is better to stop at anodized metal. This is the most durable coating known at present. Installation of a slatted ceiling is not difficult. It is quite within the power of even a single craftsman who does not have the opportunity to attract an assistant. The lightness of the components allows a woman to install them on her own.</ ul>

The principle of stringer installation.It is best to place the slatted panels in a direction perpendicular to the wall with windows. But if you are placing a window in the end wall of a long narrow room, you should prefer a direction perpendicular to the long walls. This will help to visually change the proportions of the room to better ones. When installing spotlights, you will need to cut holes in the panel. To do this, draw a circle of the desired diameter and make a series of cuts from the center, bending them to the back of the ceiling. In this case, you should make cuts more often so that the bent elements are as narrow as possible. When installing, remember that scratches on the front side of the panel can deprive the new ceiling of some of its attractiveness. When choosing the type of panel coating, it is better to stop at anodized metal. This is the most durable coating known at present. Installation of a slatted ceiling is not difficult. It is quite within the power of even a single craftsman who does not have the opportunity to attract an assistant. The lightness of the components allows a woman to install them on her own.</ ul>