When carrying out repairs in a room, it is not uncommonhave to be finished. This facing material is known for its universal properties: it is strong, fire-resistant, has excellent soundproofing properties. The low cost and light weight of this base have elevated it to the rank of the most popular brands of the construction plan. Despite a number of excellent qualities, this material has a fairly fragile base, which can quickly collapse and undergo changes. In this case, it is necessary from plasterboard. It is carried out quite easily, and you can do it yourself. Drywall, unfortunately, is a fragile and weak material, so punching a hole in it is not difficult.

Drywall, unfortunately, is a fragile and weak material, so punching a hole in it is not difficult.

The causes of the appearance of defects on the surface

The main reason for the occurrence of all kinds of defects on the outer layer is the violation of the rules of interaction with the gypsum base and non-compliance with basic standards.

Scheme for sealing cracks in plasterboard.Plasterboard walls can be significantly damaged due to violations in the installation technology. For example, the use of devices that are not suitable for this material: fasteners, profiles, putty, backfill. Thus, profiles on a metal base must be steel, their thickness must be 0.6 mm. This metal, when in contact with air, must prevent the formation of corrosion on the surface. Reducing such numbers leads to a change in the hardness of the entire structure. For finishing walls with plasterboard, special fasteners are used that do not form rust. Any of the structures is designed to be fixed with a certain element. Failure to comply with distances. An acceptable distance between parts of plasterboard sheets will be 57 mm, and the clearance of the floor and enclosing elements is 10 mm. If you want to hang something on the plasterboard walls, use special dowels. Their sizes should match the thickness of the coating. Light weight loads are hung on gypsum panels using hooks or nails. Massive cabinets or shelves are attached with plastic dowels or screws. Return to contents</a>

Scheme for sealing cracks in plasterboard.Plasterboard walls can be significantly damaged due to violations in the installation technology. For example, the use of devices that are not suitable for this material: fasteners, profiles, putty, backfill. Thus, profiles on a metal base must be steel, their thickness must be 0.6 mm. This metal, when in contact with air, must prevent the formation of corrosion on the surface. Reducing such numbers leads to a change in the hardness of the entire structure. For finishing walls with plasterboard, special fasteners are used that do not form rust. Any of the structures is designed to be fixed with a certain element. Failure to comply with distances. An acceptable distance between parts of plasterboard sheets will be 57 mm, and the clearance of the floor and enclosing elements is 10 mm. If you want to hang something on the plasterboard walls, use special dowels. Their sizes should match the thickness of the coating. Light weight loads are hung on gypsum panels using hooks or nails. Massive cabinets or shelves are attached with plastic dowels or screws. Return to contents</a>

Required tools for installation

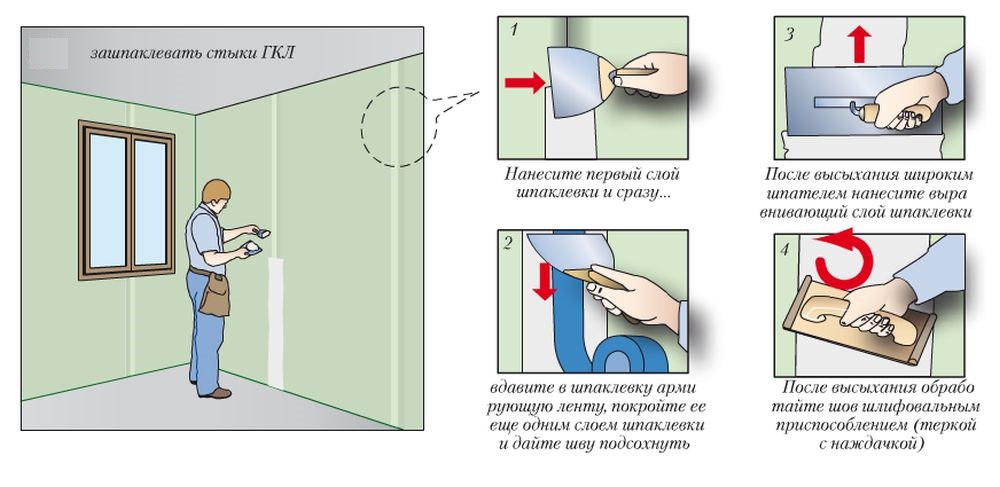

This: Scheme of plasterboard joint filling.

Scheme of plasterboard joint filling.

- knife;

- drill;

- putty knife;

- sealant;

- putty;

- sandpaper;

- Oil paint;

- drywall.

The length of the knife should be 15-30 cm. Return to contents</a>

The appearance of cracks at the seams

Such manifestations are associated with non-compliancetechnologies in the process of sewing the frame with sheets and making mistakes. However, one of the reasons may also be too sharp a temperature drop, for example, in winter. To get rid of this problem, you need to do the following:

Before work, you should outline the perimeterblanks for a future patch. When carrying out such repairs, putty can be replaced with acrylic. The method for processing seams will be similar. It is not recommended to use silicone: it has a greasy composition and cannot be painted. If the cracks occupy a large surface of the sheet, the wall is repaired using a fiberglass mesh. It is glued to the entire base of the wall with putty for processing gypsum board seams. The surface is treated with finishing putty. Then, sanding and priming of the damaged surface are carried out. Then small holes are eliminated. A good reason for this type of damage is mechanical impact of household significance. Such a hole is called a dent or hole. In this case, wall repair is associated with cutting off the damaged area, priming and puttying it. Return to the table of contents</a>

Before work, you should outline the perimeterblanks for a future patch. When carrying out such repairs, putty can be replaced with acrylic. The method for processing seams will be similar. It is not recommended to use silicone: it has a greasy composition and cannot be painted. If the cracks occupy a large surface of the sheet, the wall is repaired using a fiberglass mesh. It is glued to the entire base of the wall with putty for processing gypsum board seams. The surface is treated with finishing putty. Then, sanding and priming of the damaged surface are carried out. Then small holes are eliminated. A good reason for this type of damage is mechanical impact of household significance. Such a hole is called a dent or hole. In this case, wall repair is associated with cutting off the damaged area, priming and puttying it. Return to the table of contents</a>

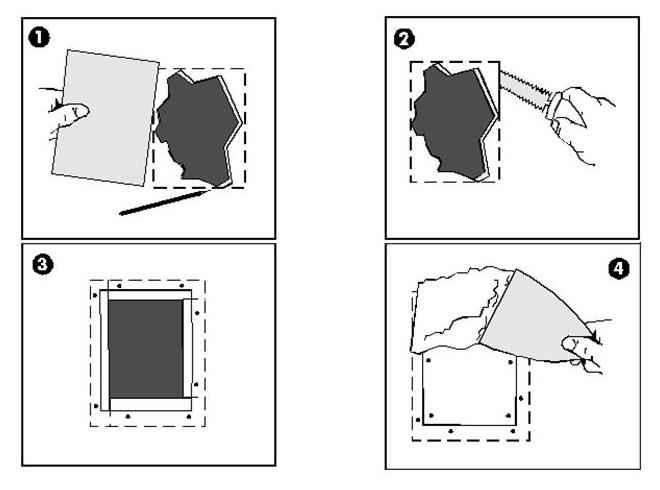

How to get rid of large diameter holes?

Such repairs take place in the following form: Scheme of patching a hole in a plasterboard wall: 1 - preparing the overlay, 2 - cutting for the overlay, 3 - installing the overlay, 4 - filling.

Scheme of patching a hole in a plasterboard wall: 1 - preparing the overlay, 2 - cutting for the overlay, 3 - installing the overlay, 4 - filling.

To minimize the amount of household mechanical impacts on plasterboard sheets, a double layer of this material should be installed. Return to contents</a>

Additional points and recommendations

Repair of corner zones. When working with plasterboard sheets, the problem of chipped corners often arises. To do this, you need to do:

Here it is necessary to strictly monitor the correctnesslines, otherwise the angle will be uneven. Restoration of a plaster base under painting. The technique for carrying out repair work is carried out according to a similar scheme discussed earlier. An important place here is occupied by the process of applying paint to the surface. The main problem will be the correct selection of the desired shade of enamel. If it is impossible to carry out such actions, the entire surface is painted again. Drywall repair is also carried out under wallpaper. To carry out such actions, the sheets should be well wetted so that they can be easily removed. As soon as the wallpaper is removed, the nature of the damage should be assessed. Significant damage to the material indicates its complete replacement. This method will be more convenient and inexpensive. Usually, as a result of removing wallpaper from the surface, the paper base of the drywall is torn. As a result, the surface is bumpy and rough. Such uneven areas can be eliminated by simply wetting the surface. After moistening the base, the top layer of drywall is scraped off with a knife. Only protruding and interfering elements should be removed. When removing protruding parts, do not scratch the surface too much, which may cause new surface defects to appear. You can also use sandpaper to clean the paper base.</ ul>