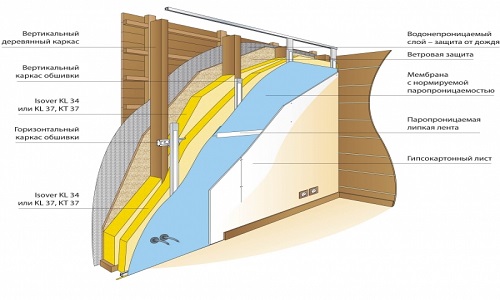

Today, plasterboard is one of the most popular materials for renovating a room or leveling various surfaces. Scheme of wall covering with plasterboard.It can also be used to construct various built-in structures and suspended ceilings. It is not surprising that today many are interested in how to sheathe a room with plasterboard (GKL).

Scheme of wall covering with plasterboard.It can also be used to construct various built-in structures and suspended ceilings. It is not surprising that today many are interested in how to sheathe a room with plasterboard (GKL).

Preparatory work

To panel a room, you will need the following tools and materials: Tools for finishing walls with plasterboard.

Tools for finishing walls with plasterboard.

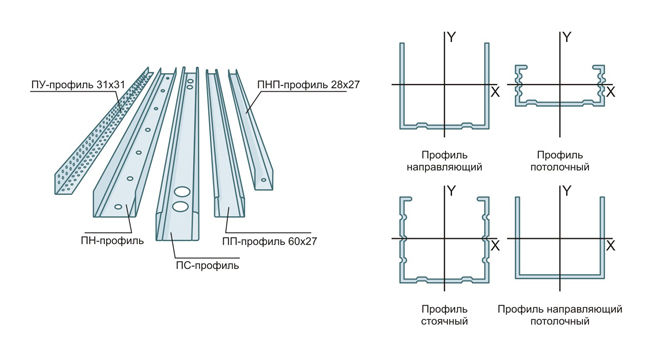

If you need to sheathe a room wherethere is high humidity, that is, a bathroom, then you will need special plasterboard that is resistant to moisture. It contains special additives that allow you to achieve this effect. In addition, it is necessary to pay attention to the fact that the thickness of the sheets should be at least 12 mm. The calculation of the number of sheets is carried out based on the parameters of the room and the dimensions of the sheets themselves. It is important to purchase plasterboard with a small reserve, as this will help to avoid difficulties in those situations when some of the material turns out to be defective. Types of profiles for plasterboard.Before starting work, you need to perform certain preparatory actions. First of all, this concerns leveling the surface of the walls, eliminating its defects, cracks. All cracks, protrusions, depressions, etc. must be eliminated immediately. To make the surface even, the sheets are sewn onto a pre-installed frame made of metal elements. Another advantage of this technology is that the metal frame allows you to arrange various decorative elements, such as arches, shelves or niches. The metal profile is fastened along the entire perimeter. For this work, you need to use dowels. The posts will be inserted into the guides, the distance between them is about 60 cm. Such a structure will be a sheathing. Return to the table of contents</a>

Types of profiles for plasterboard.Before starting work, you need to perform certain preparatory actions. First of all, this concerns leveling the surface of the walls, eliminating its defects, cracks. All cracks, protrusions, depressions, etc. must be eliminated immediately. To make the surface even, the sheets are sewn onto a pre-installed frame made of metal elements. Another advantage of this technology is that the metal frame allows you to arrange various decorative elements, such as arches, shelves or niches. The metal profile is fastened along the entire perimeter. For this work, you need to use dowels. The posts will be inserted into the guides, the distance between them is about 60 cm. Such a structure will be a sheathing. Return to the table of contents</a>

Tips for plasterboard plastering

To make your work easier, I prepared the sheets in advance.are marked and cut. If there are windows in the room, this is taken into account at the stage of marking. The sheets of material are made according to the location of the window and its parameters. Then the plasterboard is attached to the metal profile already installed on the wall. Scheme of frameless fastening of plasterboard.When fixing the material, use self-tapping screws, they are sunk all the way into the surface. Place the sheets on the surface in a staggered manner, otherwise there is a risk of the joints matching in height. Such a small detail will reduce the strength of the entire structure. If you also need to cover the ceiling with plasterboard, then you need to focus on the lowest angle. Then you need to go down from the ceiling surface at a distance equivalent to the thickness of the material, after which a mark is made on both sides of the angle at the level of the specified distance from the ceiling. Next, a line is drawn from the initial angle to the next one. Its evenness must be monitored, since all further work will depend on this line. To control it, you will need a building level. In this way, the remaining corners are marked. When the perimeter is marked, you can proceed to a similar procedure with the ceiling. This work includes marking the joints of the sheets. Sheathing with plasterboard will be carried out along these lines. When marking, you must also take into account the places where the profiles will be located. Plumb lines are fixed on these lines, the distance between them is 40 cm, but not more. This is necessary so that the plasterboard does not sag. Before starting the installation of the frame, the markings, their evenness and horizontality are carefully checked again. If they are correctly positioned, you can start installing them, the work begins with the perimeter. Fastening is carried out along the drawn line using dowels or self-tapping screws. When the work with the perimeter is finished, they proceed to fixing the guides. Along the guides, . If necessary, a soundproofing layer is installed, for which polystyrene foam will be required. It is important to take into account that polystyrene foam is fixed to the surface of the wall or ceiling before the sheathing process. Construction glue is used to fix the material. Return to contents</a>

Scheme of frameless fastening of plasterboard.When fixing the material, use self-tapping screws, they are sunk all the way into the surface. Place the sheets on the surface in a staggered manner, otherwise there is a risk of the joints matching in height. Such a small detail will reduce the strength of the entire structure. If you also need to cover the ceiling with plasterboard, then you need to focus on the lowest angle. Then you need to go down from the ceiling surface at a distance equivalent to the thickness of the material, after which a mark is made on both sides of the angle at the level of the specified distance from the ceiling. Next, a line is drawn from the initial angle to the next one. Its evenness must be monitored, since all further work will depend on this line. To control it, you will need a building level. In this way, the remaining corners are marked. When the perimeter is marked, you can proceed to a similar procedure with the ceiling. This work includes marking the joints of the sheets. Sheathing with plasterboard will be carried out along these lines. When marking, you must also take into account the places where the profiles will be located. Plumb lines are fixed on these lines, the distance between them is 40 cm, but not more. This is necessary so that the plasterboard does not sag. Before starting the installation of the frame, the markings, their evenness and horizontality are carefully checked again. If they are correctly positioned, you can start installing them, the work begins with the perimeter. Fastening is carried out along the drawn line using dowels or self-tapping screws. When the work with the perimeter is finished, they proceed to fixing the guides. Along the guides, . If necessary, a soundproofing layer is installed, for which polystyrene foam will be required. It is important to take into account that polystyrene foam is fixed to the surface of the wall or ceiling before the sheathing process. Construction glue is used to fix the material. Return to contents</a>

Methods of plasterboard plating

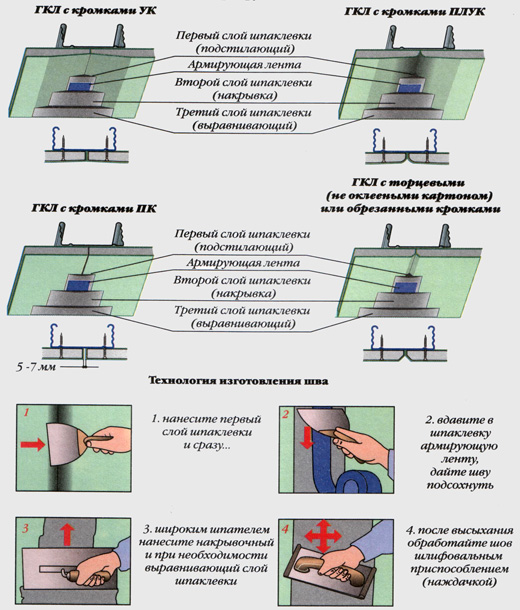

Plasterboard sheathing can be done in three ways. This is the installation of the material on metal guide profiles, on wooden slats and installation using glue. Return to the table of contents</a>Using guides Scheme of processing plasterboard seams.The beginning of the work is associated with the execution of marking, for which any suitable tool is used: a plumb line, a building level, etc. If earlier it was said about marking with a building level, now it is necessary to say the same about the plumb line, since some may find such work easier than in the previous case. In the corner of the room, in this case it does not matter which one, the plumb line is located. Its position will be an indicator for installing the first profile. A vertical line is drawn along the location of the plumb line, similar lines need to be drawn along the rest of the wall. The distance in this case will be determined by the parameters of the sheet of material. Fasteners are installed on the marked lines. The distance between them is 30-40 cm. Fasteners are made of straight hangers. For one element, it is necessary to use dowels in the amount of 2 pieces. It is necessary to pay attention to such a small element as a dowel. The diameter of each should be 6 mm, but its length is selected taking into account the condition of the wall surface. If there is plaster on it, the length should be equal to 5-6 cm, if there is no plaster layer, then the length is 4 cm. When the fastening of the hangers is completed, proceed to the installation of vertical posts. They are fastened to the hangers. The location of each post must be strictly vertical, so this work is carried out with a building level. The fastening stage is carried out with metal screws. After this, it is necessary to attach the guide profiles to the posts, which will be located across. As a result, we get the very frame that will be needed for sheathing with plasterboard. The main part of the work has been successfully done, it remains to lay the sheets. It is recommended to start from the upper corner. The distance between the fasteners is 2.5-3 cm. The dowels should be located 1 cm from the edge of the material. After screwing in, the heads of the screws or dowels are sealed with putty. The joints must be covered with a serpyanka mesh. Then a thin layer of putty is applied to the surface. This completes the work. Return to Contents</a>Application of adhesive composition

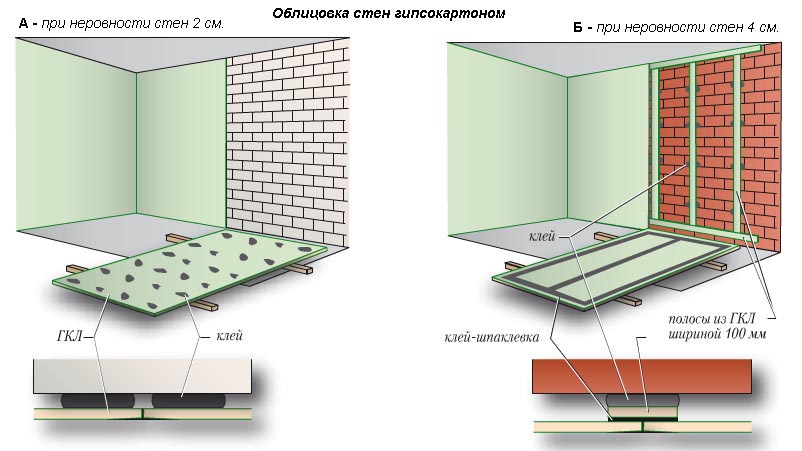

Scheme of processing plasterboard seams.The beginning of the work is associated with the execution of marking, for which any suitable tool is used: a plumb line, a building level, etc. If earlier it was said about marking with a building level, now it is necessary to say the same about the plumb line, since some may find such work easier than in the previous case. In the corner of the room, in this case it does not matter which one, the plumb line is located. Its position will be an indicator for installing the first profile. A vertical line is drawn along the location of the plumb line, similar lines need to be drawn along the rest of the wall. The distance in this case will be determined by the parameters of the sheet of material. Fasteners are installed on the marked lines. The distance between them is 30-40 cm. Fasteners are made of straight hangers. For one element, it is necessary to use dowels in the amount of 2 pieces. It is necessary to pay attention to such a small element as a dowel. The diameter of each should be 6 mm, but its length is selected taking into account the condition of the wall surface. If there is plaster on it, the length should be equal to 5-6 cm, if there is no plaster layer, then the length is 4 cm. When the fastening of the hangers is completed, proceed to the installation of vertical posts. They are fastened to the hangers. The location of each post must be strictly vertical, so this work is carried out with a building level. The fastening stage is carried out with metal screws. After this, it is necessary to attach the guide profiles to the posts, which will be located across. As a result, we get the very frame that will be needed for sheathing with plasterboard. The main part of the work has been successfully done, it remains to lay the sheets. It is recommended to start from the upper corner. The distance between the fasteners is 2.5-3 cm. The dowels should be located 1 cm from the edge of the material. After screwing in, the heads of the screws or dowels are sealed with putty. The joints must be covered with a serpyanka mesh. Then a thin layer of putty is applied to the surface. This completes the work. Return to Contents</a>Application of adhesive composition Wiring installation diagram for plasterboard.This method is called frameless. However, preparation for work is similar: it is necessary to eliminate all irregularities and defects of the wall surface. The walls need to be treated with putty, after which they are treated with a primer when the putty dries. After some time, when the materials dry, the wall needs to be treated with an adhesive composition. It does not matter what will be processed, sheets of material or the wall itself, experts advise using the second option. The entire area of the wall does not need to be processed, you just need to divide the surface into sectors and apply the required amount of glue, then fix the drywall. Thus, two options for cladding were considered. Which one to use is up to you.

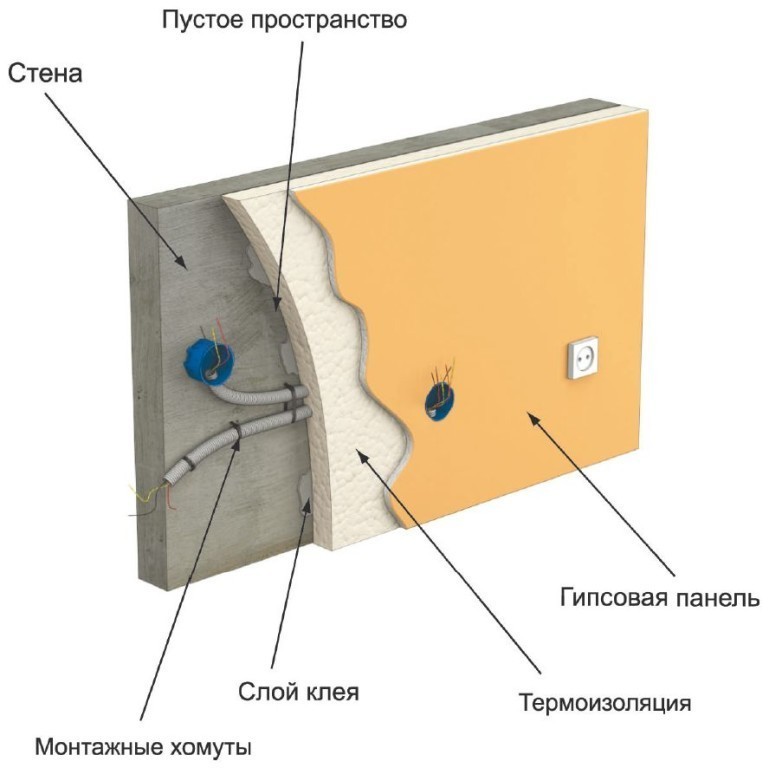

Wiring installation diagram for plasterboard.This method is called frameless. However, preparation for work is similar: it is necessary to eliminate all irregularities and defects of the wall surface. The walls need to be treated with putty, after which they are treated with a primer when the putty dries. After some time, when the materials dry, the wall needs to be treated with an adhesive composition. It does not matter what will be processed, sheets of material or the wall itself, experts advise using the second option. The entire area of the wall does not need to be processed, you just need to divide the surface into sectors and apply the required amount of glue, then fix the drywall. Thus, two options for cladding were considered. Which one to use is up to you.