To make such doors we usevarious materials. You can choose panel, panel, solid wood, veneer, MDF, chipboard, plywood or combining several materials. The design of their construction, the way of opening is important for those who want to save space, in addition, some of these doors are stylish, fashionable and beautiful. In the latter case, we are talking about sliding or sliding doors. To install sliding doors with your own hands, you need a minimum of skills and tools. Sliding doors are very convenient as they help save space in the room.

Sliding doors are very convenient as they help save space in the room.

The main characteristics of the data

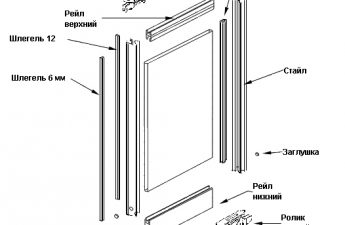

To perform a quality installation, you shouldknow the basic elements of the design. Such doors can be double-leaf, single-leaf. Their fastening and guides can be located at the top or bottom, or both. If desired, the guide can be recessed into the floor or ceiling. It is important to install them well, since sometimes they rattle, this is especially true for doors with one guide. There are also accordion doors, they consist of two or more folding leaves. Doors consist of leaves, which are: Construction of sliding doors.

Construction of sliding doors.

- parallel-sliding;

- sliding-folding.

Interior doors are movable, most often for themuse a lighter material, although some options are made of solid wood and glass elements. Wooden board, wood adhesive, chipboard, veneer are the most common in their manufacture. There are also options made of impact-resistant glass, its connection with wooden parts. An original and simple design of such a device is made of frames similar to baguettes, covered with a special fabric. The sliding structure consists of the following elements:

- rails under the carriage, rollers;

- Fasteners, restraints, fixing parts;

- sashes, trims, trim;

- accessories (lock, pens).

There are two types of sliding mechanisms: Sliding doors have poor sound insulation, so this should be taken into account when installing them.

Sliding doors have poor sound insulation, so this should be taken into account when installing them.

- embedded (hides in the wall and is invisible);

- hinged (visible on the wall).

The design of these elements may differ forof each type of door, but the operating principle is the same. The rollers are made of silicone-coated material, with silent bearings inside them, so there is very little noise when the doors are operating. The doors have at least two such rollers. If the doors are heavy, about 80 kg, or large, they are equipped with a large number of rollers - four per door. Positive features:

- space is saved;

- easy to open, resistant to drafts, jerks of air;

- you can install an automated system.

They have some negative aspects: Sliding door mechanism.

Sliding door mechanism.

- low level of noise and heat insulation, they are not put in bathrooms, bathrooms;

- Locks and fittings are more expensive than for conventional ones;

- the plane of the wall along which they move should be free of decorative objects, wires, etc.

The roller mechanism can be either top orbottom or be placed both at the top and bottom. The advantage of only the top is the additional aesthetics: the doors seem to hang over the surface, there are no thresholds, but the structure is a little unstable. Return to contents</a>

Tools and materials for installation

Return to Contents</a>

Installation: practical recommendations

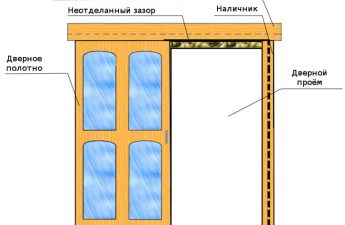

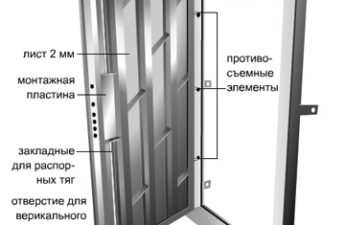

The door leaf fastenings should be selected independing on the material the door itself is made of. You can make an interior door yourself, you just need to have some skills and the necessary tools. Basically, the design of simple doors consists of two or one leaf moving along guides. Their installation is not as easy as it seems at first glance. Below is a step-by-step process of fixing them and bringing them into a functional form with some independent work on their manufacture. The structure is placed against the wall surface. Its level is marked from above. Now it is tried on in the opening, marked from above. It is necessary to carefully make sure that it will stand level. 70 mm are counted to the ceiling, this mark is indicated by a straight line horizontally. This is where the profile is fixed. A 50x50 mm beam is fastened to the wall with self-tapping screws. It is twice as wide in length as the opening, and is also set strictly horizontally. The profile is fixed to the beam, its end. It is important to ensure that it is straight and position it as level as possible, regardless of other elements, including the beam. Then calculate the place for fastenings on both sides of the profile (the thickness of the web is divided in two, the distance from the wall is added to the result). It is easily fixed with screws. Do the same on the other side.

The door leaf fastenings should be selected independing on the material the door itself is made of. You can make an interior door yourself, you just need to have some skills and the necessary tools. Basically, the design of simple doors consists of two or one leaf moving along guides. Their installation is not as easy as it seems at first glance. Below is a step-by-step process of fixing them and bringing them into a functional form with some independent work on their manufacture. The structure is placed against the wall surface. Its level is marked from above. Now it is tried on in the opening, marked from above. It is necessary to carefully make sure that it will stand level. 70 mm are counted to the ceiling, this mark is indicated by a straight line horizontally. This is where the profile is fixed. A 50x50 mm beam is fastened to the wall with self-tapping screws. It is twice as wide in length as the opening, and is also set strictly horizontally. The profile is fixed to the beam, its end. It is important to ensure that it is straight and position it as level as possible, regardless of other elements, including the beam. Then calculate the place for fastenings on both sides of the profile (the thickness of the web is divided in two, the distance from the wall is added to the result). It is easily fixed with screws. Do the same on the other side. Sliding door design options.The bolts are not inserted into the carriage all the way, they protrude slightly. The assembled carriage is inserted into the profile, sliding is checked. Rail parts are installed to limit the stroke. Then 15 mm are counted from the sash edge, one hole is drilled in the middle on each side. There is a groove under the profile at the bottom strictly in the center. The carriage fixing elements are mounted in the middle on the canvas, while retreating from the ends by 2 mm. The cutouts in the brackets are turned towards the wall. The structure is hung, it is placed against the profile, the cutout on the bracket on the right is aligned with the carriage bolt on the right. The nut with the washer is placed on the outside of the bracket, the bolt is screwed into it. The brackets are secured, the bolts are not tightened. The part at the bottom is set aside, the profile is mounted in the lower groove. Then it returns to the horizontal position with the adjustable blade. The blade latch is set to the "Open" state. The gap between the wall and the door is adjusted to approximately 5 mm, this is done as follows: a part of the sash is deflected from below until it reaches the wall, the location of the blade is marked. The nuts in the carriages are unscrewed, the door is removed and the lower profile is fixed with screws. The sash is hung again, the carriage bolts are inserted into the holes of the brackets, the nuts are not unscrewed completely, the gap between the sash and the floor is adjusted, it is 5-7 mm, after which the nuts are fixed. The trim-casing is mounted. It is made folding so that if necessary, you can get to the sash. The above installation method is also suitable for homemade sliding doors. And in finished form, they are sold complete with all the necessary spare parts. It standardly includes:

Sliding door design options.The bolts are not inserted into the carriage all the way, they protrude slightly. The assembled carriage is inserted into the profile, sliding is checked. Rail parts are installed to limit the stroke. Then 15 mm are counted from the sash edge, one hole is drilled in the middle on each side. There is a groove under the profile at the bottom strictly in the center. The carriage fixing elements are mounted in the middle on the canvas, while retreating from the ends by 2 mm. The cutouts in the brackets are turned towards the wall. The structure is hung, it is placed against the profile, the cutout on the bracket on the right is aligned with the carriage bolt on the right. The nut with the washer is placed on the outside of the bracket, the bolt is screwed into it. The brackets are secured, the bolts are not tightened. The part at the bottom is set aside, the profile is mounted in the lower groove. Then it returns to the horizontal position with the adjustable blade. The blade latch is set to the "Open" state. The gap between the wall and the door is adjusted to approximately 5 mm, this is done as follows: a part of the sash is deflected from below until it reaches the wall, the location of the blade is marked. The nuts in the carriages are unscrewed, the door is removed and the lower profile is fixed with screws. The sash is hung again, the carriage bolts are inserted into the holes of the brackets, the nuts are not unscrewed completely, the gap between the sash and the floor is adjusted, it is 5-7 mm, after which the nuts are fixed. The trim-casing is mounted. It is made folding so that if necessary, you can get to the sash. The above installation method is also suitable for homemade sliding doors. And in finished form, they are sold complete with all the necessary spare parts. It standardly includes:

- cloth, box;

- accessories, guides, rollers, bolts, fasteners.

It is not difficult to install a ready-made interior door. The stages of door installation look like this:

- fix the guide from above, between it and the wall leave 15, 20 cm for the installation of clypeus or skirting;

- sliding interior doors are mounted in the guide, at the edges are fixed limiters;

- At the top of the recoil mechanism are fixed brackets for fastening, on the lower end is fastened the lower profile;

- the staples are put on, the interior doors are suspended on the carriage bolt for adjustment, leaving a gap between the fabric and the surface;

- when fixing and installing the guide on the floor, the axis along the recoiling cloth must be symmetrical;

- The travel stops are fixed by means of a special screw;

- To give an aesthetic appearance of the design, decorative fixing elements are attached to the mounting rail.

Next, the fittings are installed, the structure is ready. Good luck with the renovation!