Today it has become very fashionable to do repairs yourselfwith your hands. And in the case when it works the first time, the result is very pleasing and encourages further practice. If you want to try making slopes on windows with your own hands, carefully read the materials below. It is quite possible that you will find answers to a number of questions related to this type of work. The part of the wall adjacent to the window opening iswindow slope, thanks to which it does not freeze. So, you installed the windows yourself or involved professional builders. But not all companies selling plastic windows include the installation of slopes in the cost of their installation. To give the window a finished and aesthetic look, the installation of slopes is necessary.

The part of the wall adjacent to the window opening iswindow slope, thanks to which it does not freeze. So, you installed the windows yourself or involved professional builders. But not all companies selling plastic windows include the installation of slopes in the cost of their installation. To give the window a finished and aesthetic look, the installation of slopes is necessary.

Slopes used for plastic windows

There are several types of window slopes. Slopes made of plaster. This type is not often used, because it has many negative properties: Painter's corners will help make the corners of your slopes even.

Painter's corners will help make the corners of your slopes even.

- short-lived;

- lose their original color (fade);

- a long process of execution (it takes time to dry each layer);

- need a subsequent refinement (priming and painting);

- slopes made of plasterboard.

This type of slopes is used much more often.Firstly, because it is easy to do. And secondly, because of the availability of the material and components. Even a non-professional can handle it. The most significant disadvantage of plasterboard is its low level of moisture resistance, but otherwise it has only advantages. Additional thermal insulation is possible if necessary. You should not use plasterboard on window slopes in rooms with high humidity. It is better to choose a more suitable option. Despite the ease of making plasterboard slopes, additional work is required: The slope must be plastered from the bottom up, using a spatula to apply the solution first with vertical and then horizontal movements.

The slope must be plastered from the bottom up, using a spatula to apply the solution first with vertical and then horizontal movements.

- putty;

- primer application;

- coloring.

Slopes made of plastic. The most optimal option in all respects. This type of slopes has a large number of positive qualities:

- aesthetic appearance;

- easy to wash off contamination;

- good sound insulation;

- the ability to choose an identical frame shade.

Installing them on windows yourself won't be a hassleyou difficulties. They are quite easy to install. In order to quickly and efficiently install plastic slopes on windows, you will need to prepare tools and materials. You will need:

- wooden rack (thickness about 1.5 cm);

- insulation (you can use mineral wool);

- perforator;

- drill;

- an ordinary knife;

- scissors for metal;

- white silicone;

- level;

- several types of screws (9.5 cm and 4.5 mm);

- building stapler;

- Staples;

- plastic (sold by strips), length 6 meters, thickness 0.8 cm;

- the starting strip of the «-shaped form;

- plastic strip f-shaped.

After all the materials and toolsare prepared, you can start working. If you have installed the windows and have not had time to remove the protective film from them, then it should be left until the end of the work on the installation of the slopes. Return to the table of contents</a>

Mounting recommendations

The whole process includes the following steps: Installation of a plastic slope. Stage 1.Preparing the walls. Take a wooden strip and 9.5 cm screws. Fasten them along the entire perimeter of the slopes. They should not protrude beyond the surface of the walls. If necessary, use a drill and a hammer drill. The slats should be positioned strictly vertically. Use a level to check the level. Step 2. Attaching the starting strip. The U-shaped plastic strip must be fixed to the outer edges of the window opening. Small 4.5 mm screws are used for this. You will subsequently insert the slope strip into the hole in this strip, called the gutter. If during installation you find a joint between individual parts of the starting strip, their corners should be carefully cut with a knife. This will result in an even and beautiful joint from the inside. Step 3. Installing the F-shaped strip. The strip is installed opposite the gutter of the starting strip. In the remaining part, which is located above the window, it is necessary to cut off the F-groove. After the edges of the strips are joined, the excess should be cut off with metal scissors. The strip is secured to a wooden strip using a construction stapler.

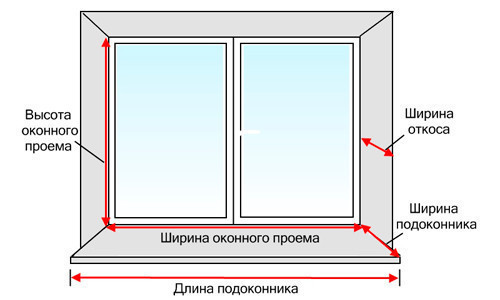

Installation of a plastic slope. Stage 1.Preparing the walls. Take a wooden strip and 9.5 cm screws. Fasten them along the entire perimeter of the slopes. They should not protrude beyond the surface of the walls. If necessary, use a drill and a hammer drill. The slats should be positioned strictly vertically. Use a level to check the level. Step 2. Attaching the starting strip. The U-shaped plastic strip must be fixed to the outer edges of the window opening. Small 4.5 mm screws are used for this. You will subsequently insert the slope strip into the hole in this strip, called the gutter. If during installation you find a joint between individual parts of the starting strip, their corners should be carefully cut with a knife. This will result in an even and beautiful joint from the inside. Step 3. Installing the F-shaped strip. The strip is installed opposite the gutter of the starting strip. In the remaining part, which is located above the window, it is necessary to cut off the F-groove. After the edges of the strips are joined, the excess should be cut off with metal scissors. The strip is secured to a wooden strip using a construction stapler. Slope installation diagram.To ensure the strength of the fastening, it is made as close to the wooden base as possible. Stage 4. Laying the insulation and installing the plastic in the prepared grooves. At this stage, accuracy plays an important role, so all measurements should be taken with special care. You can hide the flaws of the joints with silicone. Return to the table of contents</a>

Slope installation diagram.To ensure the strength of the fastening, it is made as close to the wooden base as possible. Stage 4. Laying the insulation and installing the plastic in the prepared grooves. At this stage, accuracy plays an important role, so all measurements should be taken with special care. You can hide the flaws of the joints with silicone. Return to the table of contents</a>

How to make slopes on windows with own hands from plaster?

For this type of work you will need to prepare the tools:

- paint corners;

- guides;

- lath made of wood;

- building level;

- malka (goniometer);

- self-tapping screws.

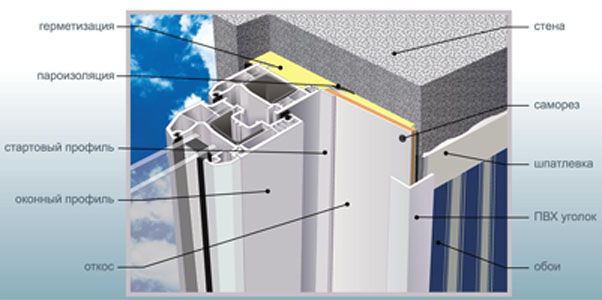

There are two main methods for making guides. Scheme of slope structure and insulation.The first method is to use boards as guides. They are placed along the edge of the future slope and the perimeter of the window, using a building level. The slope is straightened using a trowel. It can be made of plywood. The prepared plaster solution is applied to the boards and evenly distributed with a trowel. The second method is using a painter's corner. This method is a little simpler than the first, but the process itself is approximately the same. Wood is also used. A layer of plaster is applied to it, but the slope angles are made using a painter's corner. This avoids chipping. Return to contents</a>

Scheme of slope structure and insulation.The first method is to use boards as guides. They are placed along the edge of the future slope and the perimeter of the window, using a building level. The slope is straightened using a trowel. It can be made of plywood. The prepared plaster solution is applied to the boards and evenly distributed with a trowel. The second method is using a painter's corner. This method is a little simpler than the first, but the process itself is approximately the same. Wood is also used. A layer of plaster is applied to it, but the slope angles are made using a painter's corner. This avoids chipping. Return to contents</a>

Additional method of work

In order to make slopes using the second method, you need to prepare materials and tools:

- mixture for making plaster;

- finish putty;

- primer;

- plaster mesh for the upper part of the slope;

- water-emulsion;

- paint corners;

- mounting foam;

- packing of nails;

- nazhdachka (zeroing);

- mixing container;

- drill;

- stirring nozzle;

- putty knife;

- rule;

- paint brush;

- Master OK.

First, you need to prepare the slopes by removing themwallpaper or paint. You can use a spatula. Water-based paint is easily removed from the surface, but for oil paint you will need to use a special hair dryer. If you have successfully cleaned the surface, you can proceed to the next step. You need to apply a primer to those parts of the walls where the slopes will be. Wait a while for it to dry properly. According to the configuration, the guides are installed. Do not forget to use a level to check how evenly the elements are positioned. The painter's corners can be fixed with nails, polyurethane foam will also work. After this, you need to strengthen the guides with the prepared plaster. Before performing the next step, you need to take a break, since the applied mixture must dry well. The next step is to form the upper slope. It must be additionally strengthened with a painter's mesh. For a thick layer of plaster, use a chain-link mesh. A new plaster solution is diluted in a container. It should be of medium density. Make sure that there are no lumps. Each layer is applied only after the previous one has completely dried. After the plaster has dried, the surface of the slopes must be treated with a primer. First, clean the slopes from microparticles by brushing them off. Then apply the finishing putty. If you want to dilute the finishing putty in the same container in which you mixed the usual one, it must be thoroughly washed. When the finishing putty has dried, it is processed with sandpaper. With its help, defects are eliminated. If you find serious irregularities, they must be re-processed, observing the previous technology. So, the slopes are made. You can remove the protective film from the frame, wipe it and stick a layer of tape again. If your window did not have it, it is better to use masking tape before starting work. After that, the surface is primed again and after some time covered with paint. It is better to do this several times. Whatever type of slopes you choose, the important thing is that they will be made by yourself.