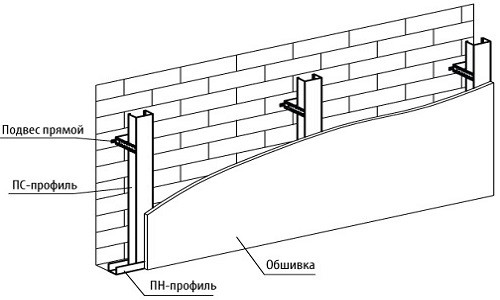

Soundproofing plasterboard walls allowssignificantly reduce audibility in the premises of apartment buildings. The frame for plasterboard partitions is attached to the supporting structures of the house, so the shock sound waves are transferred to the metal profiles and plasterboard. The installation of noise insulation helps to attenuate the sound, which greatly improves the living conditions of people. To effectively reduce the noise level, it is necessary to correctly select and install soundproofing material. Installation of a metal frame for plasterboard.

Installation of a metal frame for plasterboard.

Selection of materials for creating a soundproof layer

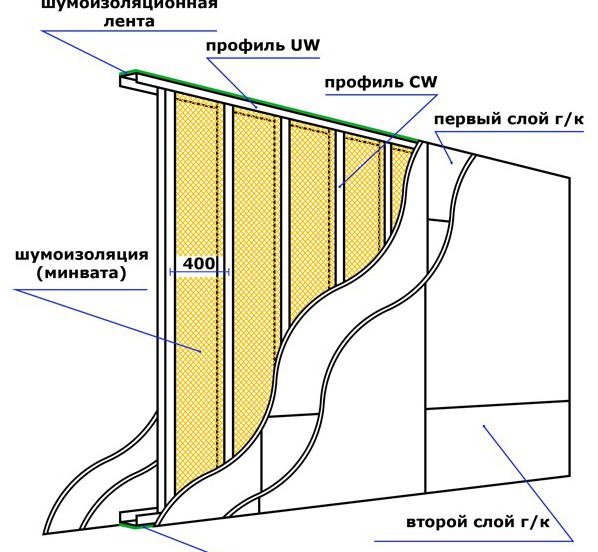

Sound insulation can be improved by installing high-quality sound-absorbing material inside the plasterboard walls. Scheme of the device of a partition from plasterboard withsound insulation. The substance forming such a layer must be durable and strong. The material selected for sound insulation must have low thermal conductivity and minimal water absorption. The absorber placed inside the walls must fit well and be easy to work with. Different materials can be used to create an intra-wall sound insulation layer. Mineral or fiberglass wool, which are well suited for sound insulation of walls, require mandatory installation of waterproofing. Noise can be reduced with the help of sprayed coatings, the use of which allows you to adjust the thickness of the insulation layer. Sound insulation of walls can be produced using modern volumetric membrane materials, which are easy to lay and have high insulating properties. Return to contents</a>

Scheme of the device of a partition from plasterboard withsound insulation. The substance forming such a layer must be durable and strong. The material selected for sound insulation must have low thermal conductivity and minimal water absorption. The absorber placed inside the walls must fit well and be easy to work with. Different materials can be used to create an intra-wall sound insulation layer. Mineral or fiberglass wool, which are well suited for sound insulation of walls, require mandatory installation of waterproofing. Noise can be reduced with the help of sprayed coatings, the use of which allows you to adjust the thickness of the insulation layer. Sound insulation of walls can be produced using modern volumetric membrane materials, which are easy to lay and have high insulating properties. Return to contents</a>

Installation of sound-absorbing panels

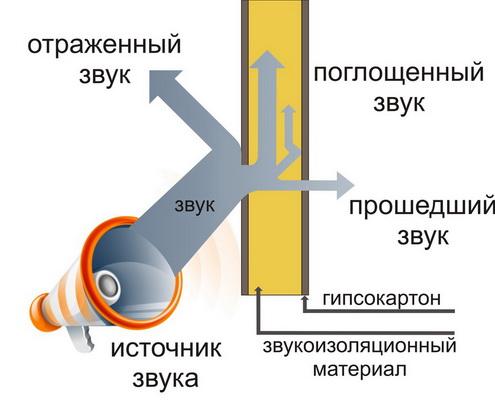

To assemble and sheathe the frame, you will need the following tools: The principle of sound absorption.

The principle of sound absorption.

- laser level;

- drill;

- Screwdriver;

- building stapler.

Materials:

- metal profile;

- elastic polymer tape;

- gypsum board (from 12 mm);

- mineral wool plates (thickness from 100 mm);

- polyethylene film;

- self-tapping screws;

- sealant.

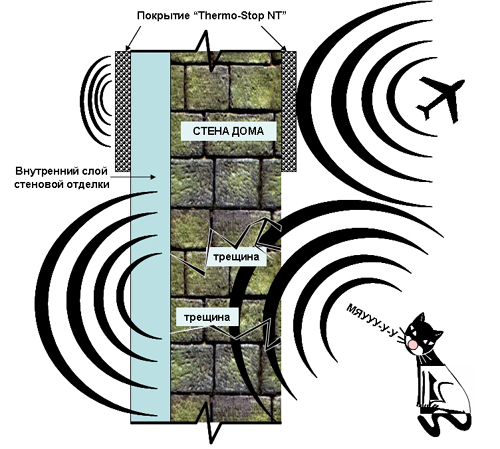

The work is carried out in the following order: The principle of sound insulation.

The principle of sound insulation.

Now you can fill the seams and do the workfinishing of plasterboard walls. The technology used allows to reduce the noise level to low values, since the combination of the air gap (before the lathing) and the loose structure of mineral wool dampens sounds well. Soundproofing of walls simultaneously performs the function of their insulation, which is especially in demand in corner apartments. If the room requires enhanced soundproofing, it can be obtained by combining rigid and elastic materials. Such combined soundproofing can be created, for example, by combining cork and fiberglass materials. Return to contents</a>

Combined barrier device

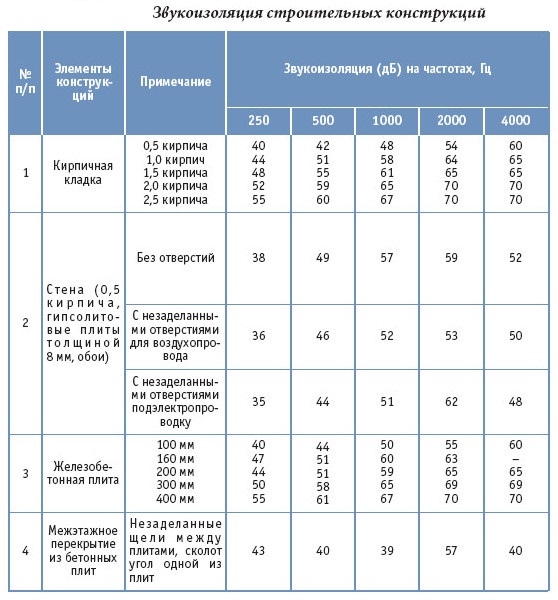

Combined noise insulation of walls is mounted on a metal frame. The following tools are required for the work: Table of sound insulation of various materials.

Table of sound insulation of various materials.

- Screwdriver;

- building stapler.

Materials:

- drywall;

- cork panels;

- glass wool;

- polyethylene film;

- self-tapping screws;

- sealant.

They work in this order:

The right choice of sound-absorbing material andinstallation carried out according to the technology will allow you to reliably isolate the room from extraneous sounds. Soundproofing of walls made of plasterboard sheets will also increase sound absorption in the apartment itself, which will not allow loud sounds to penetrate to the neighbors. The method of erecting plasterboard walls with a soundproofing layer is simple, so installation can be done on your own. The time and money spent on soundproofing are fully justified by the effect obtained from it.</ ul>