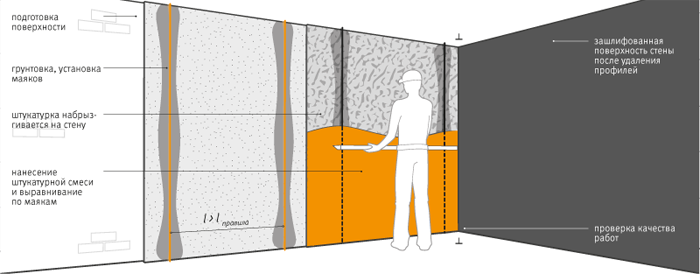

Proper preparation of walls for good quality plastering is a guarantee that the plaster covering of the walls will be reliable and even. Scheme of preparing a wall for applying plaster. To prepare a wall for plastering, you will need to purchase the following tools:

Scheme of preparing a wall for applying plaster. To prepare a wall for plastering, you will need to purchase the following tools:

How to prepare the wall for plaster?

Scheme of hanging a wall before plastering.Before plastering the walls, you will need to remove the old layer of decorative coating, if any. This will be necessary so that the new layer of coating has a reliable connection with the base and is of high quality. If the base was painted, then before doing other work, the old layer of paint must be removed. In order to remove the enamel, you will need to use a spatula, a metal brush and coarse sandpaper. In this case, you can also use an enamel remover. If the base was pasted over with wallpaper, you will need to remove the old wallpaper with a spatula. In places where the wallpaper does not peel off, you should use a solution for removing wallpaper. Before applying the solution, you will need to read the instructions. If there is a layer of old plaster, it is recommended to remove it completely, since in this case there is a possibility that the new finishing layer may begin to peel off the wall at the same time as the old one. This can be explained by the fact that primers were not used in the construction process earlier, and sand and cement plaster does not have the best adhesion. Therefore, the plaster will need to be knocked off the concrete walls. It is also necessary to pay attention to the places where the wall panels are connected to the outer wall.

Scheme of hanging a wall before plastering.Before plastering the walls, you will need to remove the old layer of decorative coating, if any. This will be necessary so that the new layer of coating has a reliable connection with the base and is of high quality. If the base was painted, then before doing other work, the old layer of paint must be removed. In order to remove the enamel, you will need to use a spatula, a metal brush and coarse sandpaper. In this case, you can also use an enamel remover. If the base was pasted over with wallpaper, you will need to remove the old wallpaper with a spatula. In places where the wallpaper does not peel off, you should use a solution for removing wallpaper. Before applying the solution, you will need to read the instructions. If there is a layer of old plaster, it is recommended to remove it completely, since in this case there is a possibility that the new finishing layer may begin to peel off the wall at the same time as the old one. This can be explained by the fact that primers were not used in the construction process earlier, and sand and cement plaster does not have the best adhesion. Therefore, the plaster will need to be knocked off the concrete walls. It is also necessary to pay attention to the places where the wall panels are connected to the outer wall. Wall priming scheme.In most cases, these seams are empty, and the plaster is present only on top. It is recommended to treat such places with construction foam before finishing. On walls made of plaster and brick, it is also recommended to knock off the entire plaster layer for safety reasons. However, in this case, you can only clean those gaps where the plaster is peeling off the wall. In order to check the strength of the old layer of plaster, you will need to tap the mortar with a hammer. In problem areas, the construction mixture will ring. In places where the mixture holds well, no sounds will be heard. Return to contents</a>Cleaning the base and priming Beforeknock down the plaster, you will need to determine the location of the electrical wiring in the wall using a tester or a special detector. Before cleaning the base, disconnect the room from the power supply. After the old finishing layer is removed, all walls must be covered with a deep penetration primer. This must be done in order to be able to create a protective film and improve the adhesion of the building mixture to the base. Otherwise, the walls will absorb water from the plaster, and it will dry out before it gains strength. On smooth bases and gaps with potholes and significant differences, it is imperative to attach a plaster mesh. In most cases, plaster will adhere well to a brick wall, so such a mesh can be omitted. Return to contents</a>Preparing walls for plastering: how to install beacons?

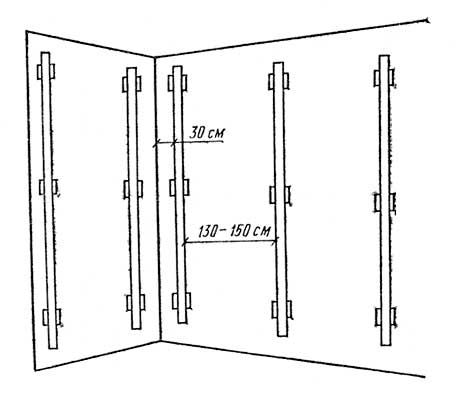

Wall priming scheme.In most cases, these seams are empty, and the plaster is present only on top. It is recommended to treat such places with construction foam before finishing. On walls made of plaster and brick, it is also recommended to knock off the entire plaster layer for safety reasons. However, in this case, you can only clean those gaps where the plaster is peeling off the wall. In order to check the strength of the old layer of plaster, you will need to tap the mortar with a hammer. In problem areas, the construction mixture will ring. In places where the mixture holds well, no sounds will be heard. Return to contents</a>Cleaning the base and priming Beforeknock down the plaster, you will need to determine the location of the electrical wiring in the wall using a tester or a special detector. Before cleaning the base, disconnect the room from the power supply. After the old finishing layer is removed, all walls must be covered with a deep penetration primer. This must be done in order to be able to create a protective film and improve the adhesion of the building mixture to the base. Otherwise, the walls will absorb water from the plaster, and it will dry out before it gains strength. On smooth bases and gaps with potholes and significant differences, it is imperative to attach a plaster mesh. In most cases, plaster will adhere well to a brick wall, so such a mesh can be omitted. Return to contents</a>Preparing walls for plastering: how to install beacons? Scheme for installing beacons under plaster.Beacons are used as vertical guides, they set the thickness of the layer for alignment. The structures are beacon profiles in the shape of the letter "T", which are made of galvanized metal. The thickness of the beacon rib should be approximately 6-9 mm. Beacons with thick ribs are more rigid, they are easier to install. However, the consumption of the leveling solution will increase by about 1.5 times. Beacons are used to get a perfectly flat base. Installation of beacons for plastering is a very important process, on which the final result will largely depend. To install beacons, you need a long building level. The length of the tool should be equal to the length of the beacons. You will also need to purchase a nylon thread and the beacons themselves. Installation of beacons should begin from opposite ends of the wall. You should step back 18-20 cm from the corner, and then set the initial profile vertically, for which you will need to use a level. Next, you need to mark its location. The beacon is fixed to the wall using a building mixture: the solution is applied to the prepared mark, after which the beacon is pressed to the wall with a level, while it is necessary to control the verticality of the structure.

Scheme for installing beacons under plaster.Beacons are used as vertical guides, they set the thickness of the layer for alignment. The structures are beacon profiles in the shape of the letter "T", which are made of galvanized metal. The thickness of the beacon rib should be approximately 6-9 mm. Beacons with thick ribs are more rigid, they are easier to install. However, the consumption of the leveling solution will increase by about 1.5 times. Beacons are used to get a perfectly flat base. Installation of beacons for plastering is a very important process, on which the final result will largely depend. To install beacons, you need a long building level. The length of the tool should be equal to the length of the beacons. You will also need to purchase a nylon thread and the beacons themselves. Installation of beacons should begin from opposite ends of the wall. You should step back 18-20 cm from the corner, and then set the initial profile vertically, for which you will need to use a level. Next, you need to mark its location. The beacon is fixed to the wall using a building mixture: the solution is applied to the prepared mark, after which the beacon is pressed to the wall with a level, while it is necessary to control the verticality of the structure. Lighthouse location diagram.The same operation is repeated for the opposite node. Between several beacons, you need to stretch a nylon thread, which can give an idea of the future plane of the wall. If you do not use a thread, then the base of the wall can go wavy, resulting in the formation of a "belly". The thread should be stretched as follows: between the beacon and the corner, you will need to drill a hole, then insert a dowel into it. You need to screw a screw into the dowel so that the head of the latter is located slightly above the level of the implied plane of the wall. In the same way, you need to screw in the screw on the other side. Between them, you should stretch the thread so that a gap of 1 mm appears between the thread and the distant beacons. You can stretch 2 threads - at the top and bottom. The remaining beacons need to be set in the same way as the previous ones. However, in this case, in addition to the level, you will also need to use a thread for control. As a result, all the beacons should create the same gap with the thread, while touching the thread with the beacon is not allowed, as this can lead to a deviation from the plane. The distance between nearby beacons should be such that the rule can freely cover it and not jump off. The installation of beacons should be done qualitatively, as the plastering of the walls along the beacons and the success of the subsequent finishing will depend on this. Return to the table of contents</a>Preparing walls for plastering: preparing the solution There are several methods for obtaining a ready-made plaster mixture:

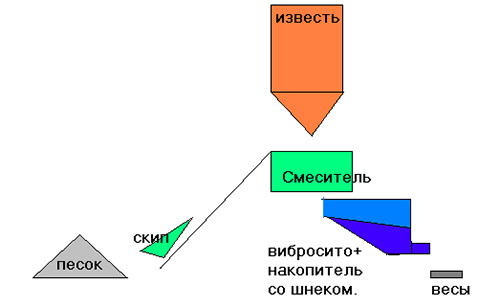

Lighthouse location diagram.The same operation is repeated for the opposite node. Between several beacons, you need to stretch a nylon thread, which can give an idea of the future plane of the wall. If you do not use a thread, then the base of the wall can go wavy, resulting in the formation of a "belly". The thread should be stretched as follows: between the beacon and the corner, you will need to drill a hole, then insert a dowel into it. You need to screw a screw into the dowel so that the head of the latter is located slightly above the level of the implied plane of the wall. In the same way, you need to screw in the screw on the other side. Between them, you should stretch the thread so that a gap of 1 mm appears between the thread and the distant beacons. You can stretch 2 threads - at the top and bottom. The remaining beacons need to be set in the same way as the previous ones. However, in this case, in addition to the level, you will also need to use a thread for control. As a result, all the beacons should create the same gap with the thread, while touching the thread with the beacon is not allowed, as this can lead to a deviation from the plane. The distance between nearby beacons should be such that the rule can freely cover it and not jump off. The installation of beacons should be done qualitatively, as the plastering of the walls along the beacons and the success of the subsequent finishing will depend on this. Return to the table of contents</a>Preparing walls for plastering: preparing the solution There are several methods for obtaining a ready-made plaster mixture: Scheme for the production of lime dry plaster mix.

Scheme for the production of lime dry plaster mix.

In order to prepare a solution from dryplaster mixture, you need to prepare a container (for example, a bucket or basin) and a construction mixer or an electric drill with a special attachment. The mixture must be placed in the container, then diluted with water. Water will make the solution plastic and will help it to set and harden. Water should be taken in such a quantity that the construction mixture acquires the consistency of dough or sour cream. In this case, everything will depend on the layer of plaster that is planned to be applied. It is quite important to add the required amount of water to the dry construction solution, since with too much or too little water the plaster will be fragile. You need to mix the plaster solution with a construction mixer or an electric drill with a special attachment installed on it. The solution must be kept for a short period of time, and then mixed again. The mixing proportions and preparation method are in most cases indicated by the manufacturer on the packaging of the dry construction solution. Return to contents</a>

How is the preparation of the walls for plaster made of wood?

Wall plastering scheme. Plaster will not stick to smooth wooden walls, so wooden bases will need to be covered with the following materials first:

Wall plastering scheme. Plaster will not stick to smooth wooden walls, so wooden bases will need to be covered with the following materials first:

- reinforced mesh;

- shingles of wood;

- reed mat.

Laths are special slats thatare obtained from pieces of round pine timber. In most cases, the length of such slats is 1-2 m. The shingles should be nailed to the base with nails one by one or with ready-made panels. The outgoing shingles consist of narrow slats of small thickness. The shingles are nailed at an angle of 45° in relation to the base of the floor. The step of the slats should be 45x45 mm. The planks must be fastened with nails so that they do not fall off. The length of the nails should be approximately 30-40 mm. After the outgoing shingle is nailed, the nails will need to be pulled out. After this, the outgoing shingle is nailed to the outgoing shingle. Before nailing, it is recommended to wet the slats with water so that they do not split. The nails must be driven in a checkerboard pattern with a small offset from the center. The outgoing shingles are made of thick slats. The width of the elements is approximately 18-20 mm. The slats of small thickness split when nailed. Rails that are too wide may start to swell from water and warp, which leads to cracks in the plaster. The exit shingles should first be nailed to all ends of the slats, with the nails driven in at an angle of 45°. The tip of the nails is directed toward the end of the shingle so that the latter is pulled. Subsequently, the shingles are secured with intermediate nails through several extension slats on the walls. The ends of the slats should not be joined exactly end to end, as they will tear the plaster during the swelling process. It is imperative to leave a gap of several millimeters. Plastering the walls can only be started after all the necessary preparatory work has been completed.</ ul>