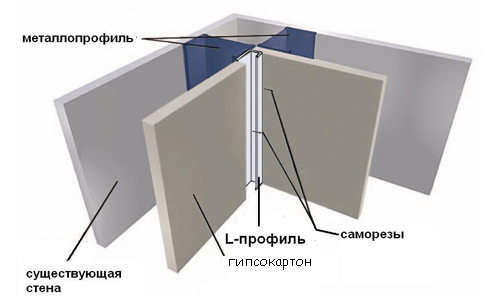

Drywall is rightfully considered one of the bestbuilding materials, especially when it comes to home improvement. Many craftsmen know exactly how to quickly and efficiently make various elements from plasterboard, such as a corner, arch, opening, etc. Plasterboard walls help craftsmen easily correct various construction irregularities. In order for the room to look neat and elegant, it is necessary to make a high-quality corner from plasterboard. Plasterboard corner diagram.

Plasterboard corner diagram.

Tools required for work

In order to make a corner from plasterboard, the master will need a small set of tools. The list of necessary devices for the work is as follows: Tools for making plasterboard corners.

Tools for making plasterboard corners.

- metal profile for GKL (this can be either a rack-mount profile or a galvanized CD);

- plasterboard sheets;

- Screwdriver;

- self-tapping screws of different diameters (approximately 9 and 9.5 mm);

- special scissors for cutting metal;

- Special bars (they will be needed if the work is done with a wooden frame).

For finishing work it is necessary to have a primer, special putty, reinforcing materials and spatulas. Return to contents</a>

Creating an Internal Angle

Plasterboard walls at the time of formationthe internal corner should already be created: the frame is covered, the surface is puttied. Therefore, to form a corner from plasterboard, it is necessary to create the second part of the wall. The instructions are quite simple: The starting profile must be installed according to the markings so that one end slightly overlaps the other.

The starting profile must be installed according to the markings so that one end slightly overlaps the other.

The inner corner is formed and then followsonly work on preparation for puttying and plastering. Fixing the profile with screws with a pitch of 25 cm will help to make the corner more rigid, because internal corners take on heavy loads, so rigidity is one of the main characteristics of such an element. If all work is performed correctly, the walls of the room will not deform over time, and the entire structure will not be covered with cracks. Return to contents</a>

Creating the outer corner

The plasterboard is screwed first to the smaller arm, then to the larger one. When forming the outer corner, it is necessary to remember that the plasterboard walls must already be created.

The plasterboard is screwed first to the smaller arm, then to the larger one. When forming the outer corner, it is necessary to remember that the plasterboard walls must already be created.

Finishing is carried out when all work onthe formation of the corner is completed. Considering that in city apartments noise spreads from above, properly organized sound insulation will help to avoid troubles and take care of the peace of both the owners of living spaces and their neighbors. In this case, the necessary material is laid between the frame and the gypsum board. The advantage of plasterboard structures (walls, corners, arches, etc.) is the presence of a void that can serve as a place for placing communications. Plasterboard corners are made more expressive and elegant with the help of a special element - a plastic (or metal) corner. Decorative plastic is a very harmonious decoration not only for doorways, but also for various niches and the now popular arches and podiums. Such material is fastened with liquid nails or fixed with a special putty. Another advantage of such a popular element is its low cost, which is ideally correlated with high strength and other indicators important for the consumer. Return to the table of contents</a>

Primer and putty

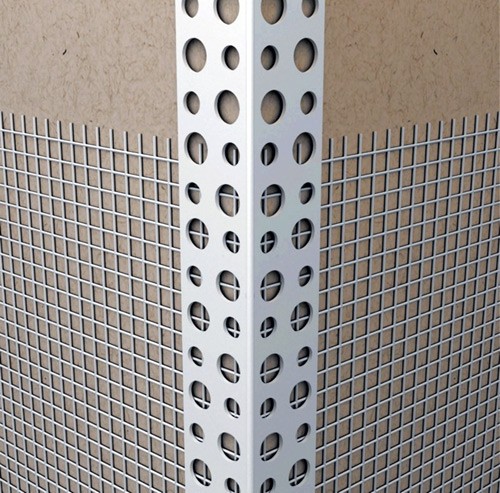

Creating a flawless corner and wall surface- a painstaking task. Craftsmen advise to glue the corner with a special construction mesh, on the surface of which the putty will be applied on both sides of the corner at a distance of 40 mm. The spatula processing is carried out without pressure and with extreme care. Also, even at the stage of forming the corner or wall, it is necessary to carefully monitor how the screw enters the drywall, its head should not protrude above the surface of the sheet and at the same time be recessed by more than 5 mm. If such a defect is detected during inspection, then it is worth unscrewing the screw and screwing it in again at a distance of 5 cm from the previous fixation point. Before finishing the corner with plasterboard, you need toglue the construction mesh to level the surface. When creating a corner, the question of the need to remove the chamfer often arises. Experts advise not to forget about this stage of the work. The chamfer should be removed at 45º. This guarantees the corners a perfect smooth shape and excellent rigidity. Removing the chamfer will ensure that there is no protrusion from the side of the metal corners, the element will fit perfectly into the formed recess. The puttying process itself is quite simple, and doing it yourself will not be difficult for a master who has previously done the work of forming corners or a wall from plasterboard:

Before finishing the corner with plasterboard, you need toglue the construction mesh to level the surface. When creating a corner, the question of the need to remove the chamfer often arises. Experts advise not to forget about this stage of the work. The chamfer should be removed at 45º. This guarantees the corners a perfect smooth shape and excellent rigidity. Removing the chamfer will ensure that there is no protrusion from the side of the metal corners, the element will fit perfectly into the formed recess. The puttying process itself is quite simple, and doing it yourself will not be difficult for a master who has previously done the work of forming corners or a wall from plasterboard:

An arch angle is used to process arches.which easily changes its shape and bends. It is fixed with the help of putty material or self-tapping screws. At the stage of preparation for puttying, it is necessary to purchase a special material - gypsum finishing putty, which is ideal for plasterboard surfaces. In addition, it is worth considering the type of gypsum board, because the type of mixture for the final processing of the wall and the corner depends on it. Depending on how the wall from gypsum board will be subsequently decorated (painting or wallpaper), the processing itself differs. If wallpaper is applied on top, then two layers of putty with subsequent sanding are enough. When the wall is being prepared for painting, then after thoroughly cleaning the first layer, three or four more should be applied, each of which should be cleaned to an ideal state. Using the listed useful tips, the question of how to make a corner from gypsum board should not arise.