How to make beams on the ceiling with your own hands?Nowadays it has become very popular to do country style ceiling finishing using special beams. A ceiling with false beams will give the interior of the room an original extravagant look. Scheme of the beam ceiling device.Decorative beams on the ceiling can be mounted independently. The internal voids of these elements make it possible to hide various ceiling communications and electrical wiring. Wood is often preferred as a material for beams. Elements made of wood must be properly connected to each other. The material must be dry and of high quality. The elements can be joined at an angle. But such installation is quite complex and requires the involvement of specialists. If you decide to do the work yourself, you can choose a simpler type of finishing, but no less effective. It is much easier to connect individual parts of the beams using bars.

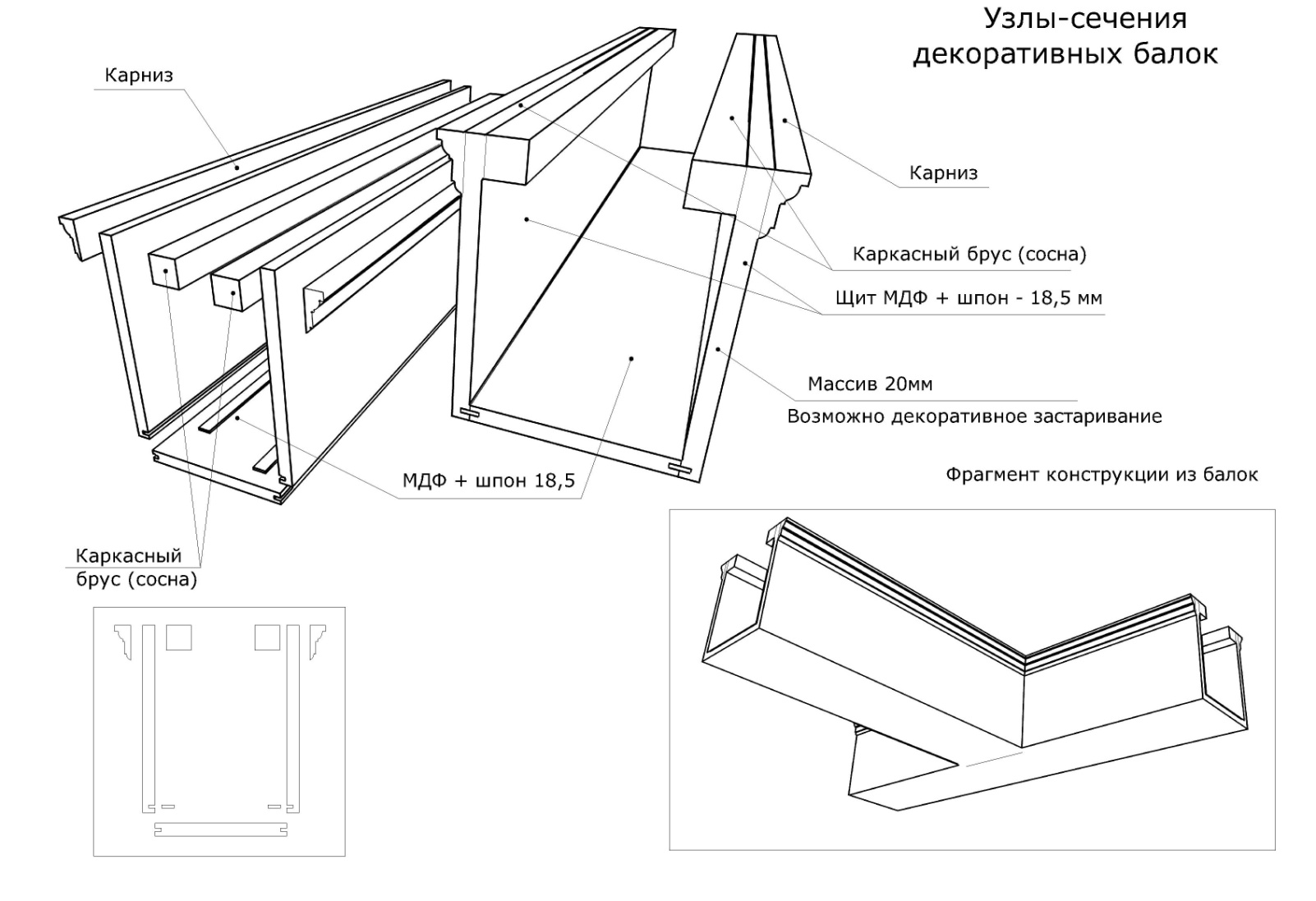

Scheme of the beam ceiling device.Decorative beams on the ceiling can be mounted independently. The internal voids of these elements make it possible to hide various ceiling communications and electrical wiring. Wood is often preferred as a material for beams. Elements made of wood must be properly connected to each other. The material must be dry and of high quality. The elements can be joined at an angle. But such installation is quite complex and requires the involvement of specialists. If you decide to do the work yourself, you can choose a simpler type of finishing, but no less effective. It is much easier to connect individual parts of the beams using bars.

Technology of work execution

Materials and tools:

- boards made of wood;

- bars;

- PVA glue;

- plane;

- drill;

- sandpaper;

- self-tapping screws.

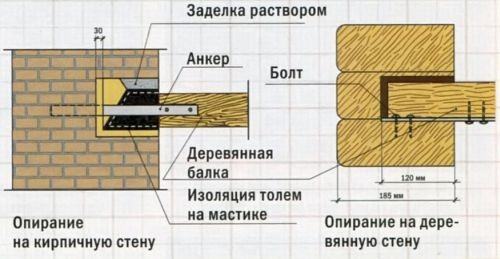

First of all, you need to mark the lines on the ceiling along which the beams will be installed. Scheme of fastening wooden beams.Using a plane, you need to fit the side panels tightly to the base, the lower part of the false beam. Then, the bars are mounted to the side elements using self-tapping screws. The bars must be fixed firmly. They must be screwed at a distance of 200 mm from each other. Then, using a drill, make holes in the bars for fastening with self-tapping screws to the base. The holes must be located at a distance of 200 mm from each other perpendicular to the bar fastenings to the side part. After this, PVA glue is applied to the contacting sides of the beams. Then the elements are connected to each other and fixed with self-tapping screws. Such a device will be durable and will protect the joints from cracking. After such a connection is made, the seam between the elements will still be visible. Therefore, the seams between the false beams must be covered with wood putty. Then they are processed with sandpaper, and all the beams on the ceiling are covered with paint. Return to the table of contents</a>

Scheme of fastening wooden beams.Using a plane, you need to fit the side panels tightly to the base, the lower part of the false beam. Then, the bars are mounted to the side elements using self-tapping screws. The bars must be fixed firmly. They must be screwed at a distance of 200 mm from each other. Then, using a drill, make holes in the bars for fastening with self-tapping screws to the base. The holes must be located at a distance of 200 mm from each other perpendicular to the bar fastenings to the side part. After this, PVA glue is applied to the contacting sides of the beams. Then the elements are connected to each other and fixed with self-tapping screws. Such a device will be durable and will protect the joints from cracking. After such a connection is made, the seam between the elements will still be visible. Therefore, the seams between the false beams must be covered with wood putty. Then they are processed with sandpaper, and all the beams on the ceiling are covered with paint. Return to the table of contents</a>

Finishing of ceiling beams

Scheme of the design of false ceiling beams.Ceiling beams that imitate old wood look great in the interior of the room. How to create such beams on the ceiling? You will need dry boards for the work. You can use used boards. You can buy new ones. To create a country style, the boards need to be aged. Materials and tools:

Scheme of the design of false ceiling beams.Ceiling beams that imitate old wood look great in the interior of the room. How to create such beams on the ceiling? You will need dry boards for the work. You can use used boards. You can buy new ones. To create a country style, the boards need to be aged. Materials and tools:

- boards made of wood;

- ax;

- sandpaper;

- brush for metal;

- Sander;

- paint;

- varnish;

- protective glasses.

First, you need to make a box.It is necessary to assemble the beams and connect them together with glue and screws as described above. Then, using an axe, make many small chips on the surface of the beams. In this case, the axe must be directed at an angle of 20 degrees to the surface. It is necessary that the chips alternate with flat areas. The depth of the chips can be about 5 mm. The more of them there are, the more impressive the product looks. After this, the seams at the joints will become invisible. Then, using a grinding machine with coarse bristles, it is necessary to process the surface of all elements. This is necessary to smooth out the sharp edges of the chips. The work must be carried out in safety glasses so that sawdust does not get into the eyes. During the grinding process, it is necessary to observe safety regulations. If the structure of the wood fibers appears on the chips during work, this will give the structure even more color. Then, an attachment with sandpaper must be installed on the grinding machine. Once again, the entire surface must be processed with a grinding machine. After this, install the soft bristle attachment and treat the surface again. At this stage, it is necessary to be especially careful. The entire surface must be carefully treated. There should be no roughness or burrs left. Return to contents</a>

Facing the structure

The wood must be protected from penetrationmoisture and microorganisms. To do this, the surface must be covered with a protective layer. You need to buy a special product that is an antiseptic and at the same time gives the surface some shade. If necessary, the surface of the beams can be covered with this product in several layers. Then you need to wait until the surface dries. After this, small roughness may appear. They must be removed with sandpaper manually. After this, dirt is removed from the surface and it is varnished. You can use colorless or tinted varnish. After drying, the structure will acquire a unique look. Finishing the ceiling with wooden beams, made using this technology, will give the room an impressive appearance, will be strong, reliable and durable.