We can all constantly monitor growthconstruction market. A large number of new tools and materials appear on it, allowing to carry out repairs or construction of various objects in the shortest possible time. Putty products are no exception, the choice of which is huge (image No. 1). Which putty should you choose so that it helps to make correct and high-quality repairs of walls? Tools for puttying.

Tools for puttying.

Types of puttying materials

Putty is a building material,designed to smooth out uneven walls and ceilings and give them smooth surfaces. There are quite a few types of such mixtures. According to their intended purpose, they are divided into starting, finishing and universal. The starting mixture is applied directly to the wall. Its layer can be quite thick. A double layer of finishing composition is applied to it. The universal mixture is used as a starting and finishing mixture. Image 1.The packaging of the dry mix is selected depending on the volume of putty work. According to their consistency, these materials are dry and ready to use. Dry ones are the most popular with consumers. They are used to level wall surfaces. They are usually sold in 25 kg bags. For small jobs, you can buy 5 kg bags. Dry compositions have a number of advantages:

Image 1.The packaging of the dry mix is selected depending on the volume of putty work. According to their consistency, these materials are dry and ready to use. Dry ones are the most popular with consumers. They are used to level wall surfaces. They are usually sold in 25 kg bags. For small jobs, you can buy 5 kg bags. Dry compositions have a number of advantages:

- the density of the solution can be made at your discretion;

- solution is prepared very simply;

- the composition is convenient in transportation and storage;

- stored can be long at any temperature of the ambient air.

The disadvantages of this mixture include:

- it takes some time to prepare the working mixture;

- the ready solution very quickly thickens and seizes, it is impossible to prepare it in large batches;

- It is necessary to dilute the composition strictly in accordance with the instructions for use.

Return to Contents</a>

Composition of putty mixture

Wall alignment scheme. Any putty consists of several components. According to this feature, it can be:

Wall alignment scheme. Any putty consists of several components. According to this feature, it can be:

- do not need to knead the solution;

- The finished solution can be stored for an unlimited period.

- an astringent;

- filler;

- solvent.

Scheme of putty application.Cement acts as a binder. Its grades may be different, but it is recommended to use M400 and M500. The filler is ordinary natural sifted sand. It must be cleaned of all impurities in the form of clay, pebbles and other inclusions. If the sand contains 5% of various inclusions, such sand is considered dirty and cannot be used to prepare putty. Only clean tap water with a temperature of no higher than 20 degrees is used. The components are mixed in the following proportions: 1 part cement, 3-4 parts clean sand, tap water. Advantages of cement putty:

Scheme of putty application.Cement acts as a binder. Its grades may be different, but it is recommended to use M400 and M500. The filler is ordinary natural sifted sand. It must be cleaned of all impurities in the form of clay, pebbles and other inclusions. If the sand contains 5% of various inclusions, such sand is considered dirty and cannot be used to prepare putty. Only clean tap water with a temperature of no higher than 20 degrees is used. The components are mixed in the following proportions: 1 part cement, 3-4 parts clean sand, tap water. Advantages of cement putty:

- water resistance;

- possibility of use in bathrooms;

Flaws: Methods of puttying.

Methods of puttying.

- when dried, the mixture gives some shrinkage;

- the solution does not have elastic properties;

- Over time, cracked surfaces can cause cracks;

- the finished mixture is poorly applied to concrete walls;

- Do not apply the compound on wooden surfaces.

- A layer of gypsum can be painted;

- gypsum has high thermal insulation properties;

- the composition has fire resistance;

- quickly dries;

- cheaply worth;

- has no smell;

- does not cause allergic reactions in humans and pets.

Flaws: Scheme of filling seams.

Scheme of filling seams.

- not suitable for puttying facades of buildings;

- It is not recommended to use it in rooms with significant differences in warm and cold temperatures;

- easily susceptible to scratches and chips;

- afraid of water.

- always get the perfect result.

Cons:

- high price;

- you can buy an explicit forgery.

Compatibility table of putties and primers.

Compatibility table of putties and primers.

- does not have excess impurities;

- easily applied to any surface (wood, cement, brick, concrete, metal, plasterboard);

- after drying it forms a very strong coating;

- after puttying and drying the surface can be painted;

- the dried layer does not crumble;

- does not smell;

- It is easily washed off from hands and from the tool.

Return to Contents</a>

Preparation of a solution from a dry mixture

Image 2.The mixer mixes the solution well and does not leave lumps. After purchasing the dry mixture, you must carefully read the instructions for preparing and using the product. Then you need to prepare a container for dilution. This can be a bucket or a basin. It is better if the container is plastic. A certain amount of dry material is poured into a container with water and mixed thoroughly. To prepare the solution in fairly large quantities, it is recommended to use a drill with a mixer attachment (image No. 2). It is advisable to select the rotation speed of the chuck within 600-800 revolutions. After complete mixing, you need to let the solution sit for 10-15 minutes. This is done so that all binders and modifiers are completely dissolved, so that air bubbles come out of the solution. Then the mass is stirred for another 3-5 minutes. It is recommended to work in rubber gloves. Return to the table of contents</a>

Image 2.The mixer mixes the solution well and does not leave lumps. After purchasing the dry mixture, you must carefully read the instructions for preparing and using the product. Then you need to prepare a container for dilution. This can be a bucket or a basin. It is better if the container is plastic. A certain amount of dry material is poured into a container with water and mixed thoroughly. To prepare the solution in fairly large quantities, it is recommended to use a drill with a mixer attachment (image No. 2). It is advisable to select the rotation speed of the chuck within 600-800 revolutions. After complete mixing, you need to let the solution sit for 10-15 minutes. This is done so that all binders and modifiers are completely dissolved, so that air bubbles come out of the solution. Then the mass is stirred for another 3-5 minutes. It is recommended to work in rubber gloves. Return to the table of contents</a>

Well-known manufacturers of putty materials

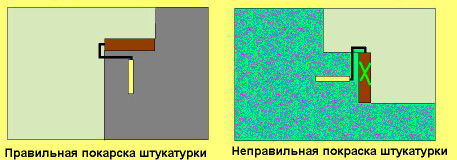

Putty is produced by many domestic and foreign manufacturers. The products of the following companies are very popular in our construction market: Scheme of painting plaster.

Scheme of painting plaster.

- "GLIMS-Production" (Russia);

- "Eunice" (Russia);

- "Ural Construction Mixtures" (Russia);

- "Starateli" (Russia);

- Volma (Russia);

- Atlas (Poland);

- "Kreisel" (Germany);

- Henkel (Germany);

- Beckers (Sweden);

- "Tikkurila" (Finland);

- United States Gypsum (USA).

The following compositions have proven themselves to be excellent:

- Knauf HP (starting and finishing);

- Ceresit CT 29 (gypsum);

- Ceresit CT 225 (finishing);

- Kreisel 662 (universal);

- SCANMIX TT (starting);

- SCANMIX LH STANDART (finish).

The starting version of Knauf HP is used forinterior wall finishing. The layer thickness can be 4-15 mm. You can work with the mixture for up to 15 minutes, then it begins to dry and becomes unusable. Complete hardening occurs in a day. The coating is highly durable, does not crack, and does not shrink. The price of the mixture is quite low. The finishing version of the putty is used in the process of preparing walls for wallpapering or painting. The surface is absolutely flat and smooth. The composition is not suitable for processing walls in the kitchen and bathroom. Ceresit CT 29 is used for leveling external and internal surfaces of brick, wood, concrete walls. It is not recommended to use the solution in conditions of high humidity. You can work with the solution for 15-20 minutes. Complete hardening occurs 15 hours after preparation. The high strength of the coating is due to the presence of reinforcing microfibers in the composition. The layer applied to the wall can reach a thickness of 20 mm. Ceresit CT 225 is used at the finishing stage. It is recommended to moisten the surface to which this type of putty is applied. You can work with the solution for an hour. The composition is applied in a layer up to 4-5 mm thick. Kreisel 662 is not afraid of moisture. It is used indoors and outdoors. When drying, it gives a slight shrinkage. If the layer thickness is more than 3 mm, cracks may appear on the surface. Choosing a putty of the listed brands and manufacturers is half the battle. Return to contents</a>

A few tips for the buyer

Techniques for applying putty to a surface using a spatula.

Techniques for applying putty to a surface using a spatula.

Without putty, no wall repair is conceivable.ceilings. The choice of this building material in stores is huge. Packages, sacks, buckets, tanks of various volumes are filled with ready-made solutions and dry mixtures. Which putty to choose? Each of the compositions has its own advantages and disadvantages. To make the right choice, you should read the instructions attached to each package, look at the material with your own eyes. Dry mixtures will cost a little less, they are easier to store.</ ul>