A coffee table is, without a doubt,useful and convenient thing. The furniture market today is full of offers of such tables made of chipboard, metal, glass and plastic. However, very often the consumer is looking for something special and exclusive, rejecting standard options. LCD tables have quite high prices,but, unlike other furniture, they are quite easy to make yourself. For such consumers, there is also a solution: make . This is not only an entertaining and interesting process, but also savings, because furniture assembled from chipboard will in any case cost significantly less than a store-bought product.

LCD tables have quite high prices,but, unlike other furniture, they are quite easy to make yourself. For such consumers, there is also a solution: make . This is not only an entertaining and interesting process, but also savings, because furniture assembled from chipboard will in any case cost significantly less than a store-bought product.

Preparatory work

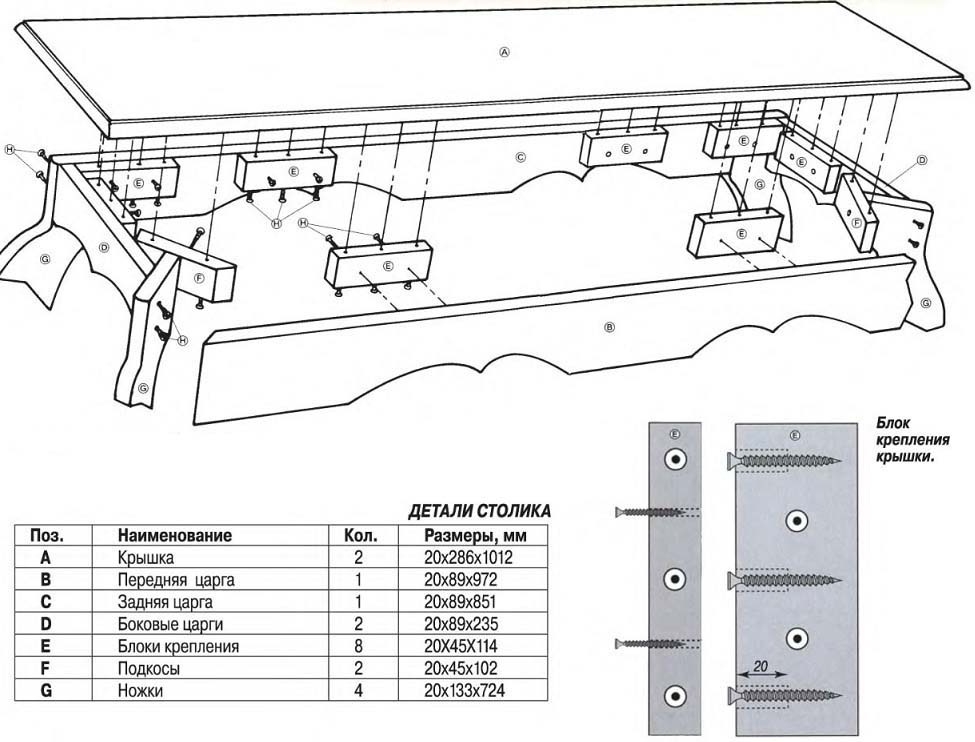

Before you start the manufacturing processtable, you need to decide on its type. After that, you should make drawings of each element and cut out the patterns. The corresponding parameters are indicated on the presented diagram. The following set of tools will help you create a coffee table: Scheme 1. Dimensions of the coffee table.

Scheme 1. Dimensions of the coffee table.

- pencil and ruler;

- roulette;

- Screws;

- a hammer;

- screwdriver;

- Particleboard, it is possible to use laminated boards 16 mm thick;

- hacksaw or electric jigsaw;

- drill;

- a furniture pipe with a diameter of 30 mm;

- flanges under the pipe;

- insulating tape;

- sandpaper;

- washing;

- the overhead profile;

- glue;

- rubber wheels.

It is necessary to place the patterns on the chipboard and trace themwith a pencil along the contour and scratch it with a nail so that the canvas does not split later. At the bottom of the tabletop pattern, cut out the contour of the legs, which need to be transferred to the parts. Drawing the central line, mark 3 holes 1.2 cm deep, and cut them out with a drill (8 mm). To control this procedure, it is recommended to use electrical tape. On the outer side of the canvas, it is also necessary to mark the locations of the holes that will be needed to support the shelves. To do this, measure 8 mm from the plane of the parts and the same distance from the beginning of the bend. The drawing will clearly show how this should be done. The ends are finished with a U-shaped profile, the texture of which should match the board. For working with chipboard, it is recommended to use an overlay profile that can cover each part on both sides without fastening grooves. The profile also needs to be glued to the legs. After that, each end must be processed with sandpaper. The last parts are connected with a dowel to the shelf, on which the profile is then put on and cut off on the other side. Return to contents</a>

Instructions for assembling the table

Scheme 2. Assembling a coffee table.The tabletop and bottom shelf are cut out of chipboard sheets, after which the flanges are screwed to the first part. You should step back 7 cm from the smaller side and draw a parallel line. You need to do the same on 2 sides of the tabletop and shelf. This will allow you to get 4 intersection points, to which you need to screw the flanges. After that, you should put rubber wheels and insert the pipes into the prepared places, securing them with bolts. Diagram 2 shows in detail the purpose of each element of the structure. To make the coffee table stable, you need to connect adjacent supports with a pipe and a joker. To give it an attractive appearance, a shelf is installed. For such purposes, the standard pipes are replaced with special parts, where the appropriate fasteners are provided. After this, you should cut the glass of the required size and insert it into the fastener. The final stage is to apply a finishing agent to the structure, but first you need to remove the "old" coating with sandpaper and a wash. If the slabs have been painted, the varnish or paint should be removed mechanically, thermally or chemically. Return to Contents</a>

Scheme 2. Assembling a coffee table.The tabletop and bottom shelf are cut out of chipboard sheets, after which the flanges are screwed to the first part. You should step back 7 cm from the smaller side and draw a parallel line. You need to do the same on 2 sides of the tabletop and shelf. This will allow you to get 4 intersection points, to which you need to screw the flanges. After that, you should put rubber wheels and insert the pipes into the prepared places, securing them with bolts. Diagram 2 shows in detail the purpose of each element of the structure. To make the coffee table stable, you need to connect adjacent supports with a pipe and a joker. To give it an attractive appearance, a shelf is installed. For such purposes, the standard pipes are replaced with special parts, where the appropriate fasteners are provided. After this, you should cut the glass of the required size and insert it into the fastener. The final stage is to apply a finishing agent to the structure, but first you need to remove the "old" coating with sandpaper and a wash. If the slabs have been painted, the varnish or paint should be removed mechanically, thermally or chemically. Return to Contents</a>

Decorating and decorating the table

There are many different ways to decorate a tabletop.different. The simplest way to decorate a table is to use wallpaper, a border or a printout of any image. The chosen method involves selecting the decor and adjusting it to the size of the tabletop. Carefully cover the table surface with varnish in 1 layer, and apply the decor to the tabletop while it is still wet. It is recommended to dry each layer of varnish for at least 24 hours, and the number of such layers depends on the wishes of the master. However, the more layers of varnish are applied, the more effective the resulting picture will be. The drawing on chipboard sheets can look quite original if you do not initially paint the tabletop. For finishing, it is recommended to pre-clean the surface with sandpaper, first with coarse sandpaper, and then with fine sandpaper, so that the paint and primer have good adhesion. If a primer is used in the finishing, it is better to use artistic or acrylic, and you can also draw with the latter. The finished drawing is covered with varnish in 3 layers.</ ul>