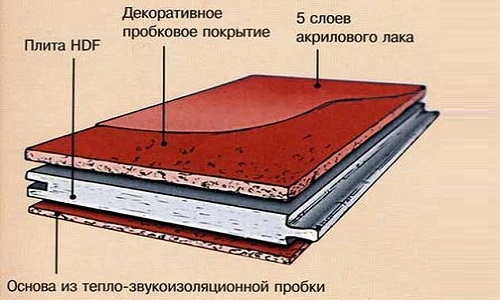

How to choose cork flooring?This question remains relevant, as many do not know all its pros and cons. The market offers a huge number of solutions for finishing the floor in an apartment or house. Each material is unique and inimitable in its own way. However, if you want to have an environmentally friendly, natural and original in its visual and mechanical characteristics coating in your home, then you should pay attention to cork. Cork floors have appeared on the market relatively recently and have already occupied a worthy niche among popular solutions for finishing a room. But how to choose a cork floor? How convenient is this material to use, because compared to other well-known floor coverings, it is relatively expensive? Construction of cork floor covering with lock.

Construction of cork floor covering with lock.

What properties should the coating have?

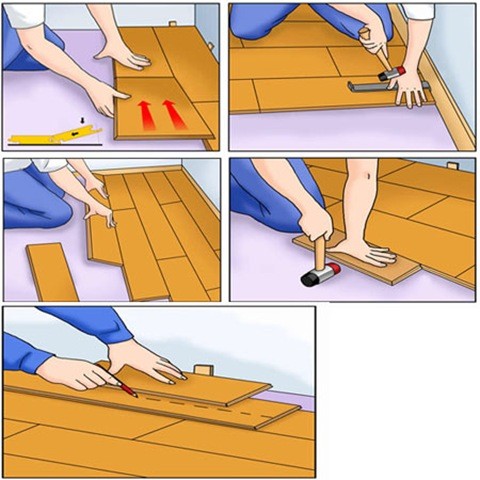

To learn how to choose cork flooring,you should familiarize yourself with its properties and composition. Such floors, regardless of the category, are excellent heat and sound insulators. Cork trees are specially grown on plantations. Carefully, using a carefully developed technology, the bark of the tree is removed from the trunk entirely. Laying cork flooring.This procedure does not harm the plant at all. The tree itself gets rid of the top layer of bark, but such material is not suitable for making the coating. After 9 years, the trunk of the cork tree is completely covered with a layer of bark, which is again suitable for use in production. After separation, the bark is processed and crushed, then heat treated and pressed. At this stage, by selecting the sizes of crushed pieces, manufacturers obtain cork veneer of various textures and colors. Due to the processing features, the mass becomes a closed system, which contains the smallest air bubbles. Air granules penetrate the structure of the coating like a honeycomb.

Laying cork flooring.This procedure does not harm the plant at all. The tree itself gets rid of the top layer of bark, but such material is not suitable for making the coating. After 9 years, the trunk of the cork tree is completely covered with a layer of bark, which is again suitable for use in production. After separation, the bark is processed and crushed, then heat treated and pressed. At this stage, by selecting the sizes of crushed pieces, manufacturers obtain cork veneer of various textures and colors. Due to the processing features, the mass becomes a closed system, which contains the smallest air bubbles. Air granules penetrate the structure of the coating like a honeycomb. Cork covering scheme.Cork tiles are a multilayer structure. The bottom layer is a pressed agglomerate with a thickness of 1 mm. Then comes a wooden base made of hardwood. The next layer is again agglomerate made of pressed cork, and only then comes the face layer. It is not particularly thick, its main task is to provide the cork floor with the proper appearance and wear resistance. This layer is made by adding fragments of valuable wood layers to the cork mass before pressing. After processing, the mass intended for the face layer is covered with vinyl or varnish. Tiles with a vinyl top layer are more moisture resistant. They can be used in rooms with high traffic, as they can withstand quite strong physical loads. Return to contents</a>

Cork covering scheme.Cork tiles are a multilayer structure. The bottom layer is a pressed agglomerate with a thickness of 1 mm. Then comes a wooden base made of hardwood. The next layer is again agglomerate made of pressed cork, and only then comes the face layer. It is not particularly thick, its main task is to provide the cork floor with the proper appearance and wear resistance. This layer is made by adding fragments of valuable wood layers to the cork mass before pressing. After processing, the mass intended for the face layer is covered with vinyl or varnish. Tiles with a vinyl top layer are more moisture resistant. They can be used in rooms with high traffic, as they can withstand quite strong physical loads. Return to contents</a>

Where are cork floors made?

Cork flooring installation diagram.Such floors come from Portugal. This country has the largest plantations of cork trees. And the technology of processing and manufacturing cork floor coverings was developed and perfected there. Cork flooring produced by Portuguese craftsmen is the most expensive, but also the highest quality. Here you pay not only for the product itself, but also for the brand. Similar floors from Spain and France have also proven themselves to be excellent. In addition to the countries of the Mediterranean basin, where the best species of cork trees grow, the market offers good examples of cork floors from Sweden and the USA. Budget options for floor coverings are most often made in Poland or China. Return to contents</a>

Cork flooring installation diagram.Such floors come from Portugal. This country has the largest plantations of cork trees. And the technology of processing and manufacturing cork floor coverings was developed and perfected there. Cork flooring produced by Portuguese craftsmen is the most expensive, but also the highest quality. Here you pay not only for the product itself, but also for the brand. Similar floors from Spain and France have also proven themselves to be excellent. In addition to the countries of the Mediterranean basin, where the best species of cork trees grow, the market offers good examples of cork floors from Sweden and the USA. Budget options for floor coverings are most often made in Poland or China. Return to contents</a>

Pros and cons of cork floors

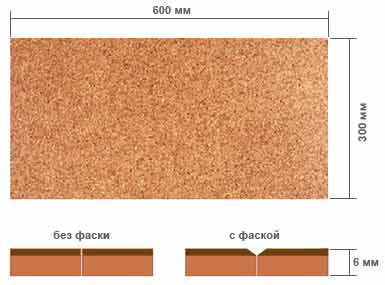

Choosing cork flooring is not easy, especially ifyou are not an expert in this matter. In order not to make a mistake, you should study all the advantages and disadvantages of this floor. So, what are its advantages? In 2005, specialists from the Biomechanical Institute in Valencia conducted studies of cork floor coverings. It was scientifically confirmed that cork floors really have the properties of reducing the load on the spine and joints. This is due to the increased elasticity and resilience of cork. No other natural floor covering has such characteristics. Drawing and types of cork floor tiles.Cork flooring springs under your feet. A dropped glass or plate will not shatter into small pieces when it lands on such a floor. It is pleasant to the touch and retains heat. If you are a music lover, your neighbors can sleep peacefully, as cork flooring is an excellent sound insulator. Cork flooring is hypoallergenic and durable. Over 100 years, cork loses only 5% of its properties. Cork floors also have disadvantages. The first and most significant is water resistance. Water softens the structure and makes the material more susceptible to wear. When choosing a cork floor, pay attention to the class of the coating: classes 21, 22, 23 are intended for rooms with low traffic flow and low impact weight. In other words, it is only suitable for a child's room. But you won't be able to walk on such a floor in heels. Deep dents and even holes will remain. But the class from 31 and above will perfectly withstand a lover of stilettos and heavy furniture. Return to the table of contents</a>

Drawing and types of cork floor tiles.Cork flooring springs under your feet. A dropped glass or plate will not shatter into small pieces when it lands on such a floor. It is pleasant to the touch and retains heat. If you are a music lover, your neighbors can sleep peacefully, as cork flooring is an excellent sound insulator. Cork flooring is hypoallergenic and durable. Over 100 years, cork loses only 5% of its properties. Cork floors also have disadvantages. The first and most significant is water resistance. Water softens the structure and makes the material more susceptible to wear. When choosing a cork floor, pay attention to the class of the coating: classes 21, 22, 23 are intended for rooms with low traffic flow and low impact weight. In other words, it is only suitable for a child's room. But you won't be able to walk on such a floor in heels. Deep dents and even holes will remain. But the class from 31 and above will perfectly withstand a lover of stilettos and heavy furniture. Return to the table of contents</a>

Types of cork floors

Options for laying underfloor heating cablescork flooring. There are two types of cork floors. The first is floating or locking floors. This type of cork flooring is a set of square panels connected using the tongue and groove principle. The system is just like laminate flooring. The thickness of such a panel is from 10 cm and is perfect for various types of premises - from offices to residential. The panels are produced already coated with varnish or vinyl. During installation, you only need to properly seal the joints of the panels themselves. The second type of cork flooring is adhesive. It is made of pressed cork granulate panels of varying thickness, usually from 3 to 6 mm. This type of cork flooring is simply glued to the surface and then varnished to ensure better moisture resistance and strength. How to choose a cork floor to win on price? Which type of flooring is cheaper? The answer is none. At first glance, the price of the first type is higher than the price of the second. But if you purchase a locking floor and install it directly on a prepared surface, with a minimum of additional costs, then a glue-down floor includes additional costs for the glue that will hold your flooring, and a special cork varnish that must be applied to your floor after installation.

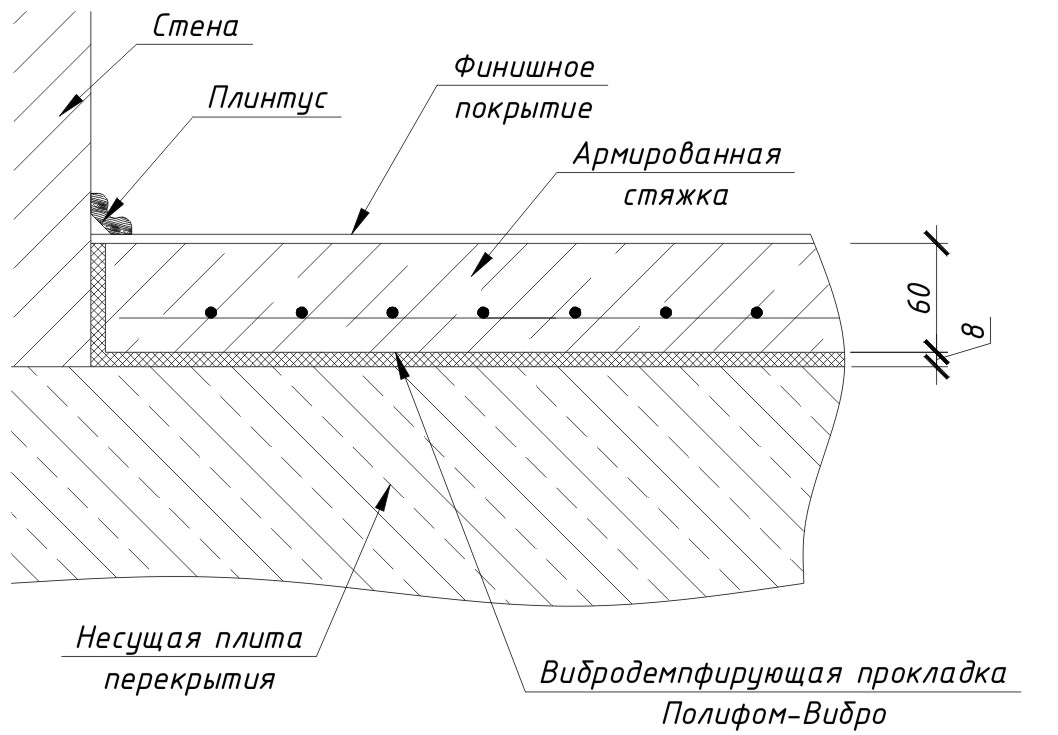

Options for laying underfloor heating cablescork flooring. There are two types of cork floors. The first is floating or locking floors. This type of cork flooring is a set of square panels connected using the tongue and groove principle. The system is just like laminate flooring. The thickness of such a panel is from 10 cm and is perfect for various types of premises - from offices to residential. The panels are produced already coated with varnish or vinyl. During installation, you only need to properly seal the joints of the panels themselves. The second type of cork flooring is adhesive. It is made of pressed cork granulate panels of varying thickness, usually from 3 to 6 mm. This type of cork flooring is simply glued to the surface and then varnished to ensure better moisture resistance and strength. How to choose a cork floor to win on price? Which type of flooring is cheaper? The answer is none. At first glance, the price of the first type is higher than the price of the second. But if you purchase a locking floor and install it directly on a prepared surface, with a minimum of additional costs, then a glue-down floor includes additional costs for the glue that will hold your flooring, and a special cork varnish that must be applied to your floor after installation. Installation of a screed for laying cork flooring.Locking cork flooring requires the same installation conditions as laminate. The base must be level, the level differences should not exceed 2 cm per 2 m of surface. When choosing a locking cork flooring, remember about the additional 10% of material that you purchase to adjust to the features of your room. It is recommended to use a special moisture-resistant underlay. Its thickness varies from 1.8 to 4 mm. Glue cork flooring is much more difficult to install and more demanding to the surface of application. You should carefully level the surface and prepare it by laying plywood or MDF, to which the fragments of the cork flooring are then glued. After this, the finished floor is varnished three times. This makes it durable and absolutely moisture-resistant. The entire technological process takes from 6 to 12 days. Do not forget that cork is a natural material. And regardless of what type of cork flooring you choose, it must certainly be acclimatized in the room in which it will be located. Return to contents</a>

Installation of a screed for laying cork flooring.Locking cork flooring requires the same installation conditions as laminate. The base must be level, the level differences should not exceed 2 cm per 2 m of surface. When choosing a locking cork flooring, remember about the additional 10% of material that you purchase to adjust to the features of your room. It is recommended to use a special moisture-resistant underlay. Its thickness varies from 1.8 to 4 mm. Glue cork flooring is much more difficult to install and more demanding to the surface of application. You should carefully level the surface and prepare it by laying plywood or MDF, to which the fragments of the cork flooring are then glued. After this, the finished floor is varnished three times. This makes it durable and absolutely moisture-resistant. The entire technological process takes from 6 to 12 days. Do not forget that cork is a natural material. And regardless of what type of cork flooring you choose, it must certainly be acclimatized in the room in which it will be located. Return to contents</a>

Care for the cork floor

According to its chemical composition, cork consists of the following components: Laying cork flooring by gluing the slabs to the base.

Laying cork flooring by gluing the slabs to the base.

Manufacturers may vary these figures,achieving certain properties from the cork flooring material. You can read the composition on the packaging and choose the one that is ideal for your room. Cork floors should not be wet or exposed to moisture for a long time. This is especially true for panel joints. It is recommended to wash with a damp, well-wrung out cloth. Do not use detergents based on solvents, abrasives and alkalis. These components destroy the structure of the floor and make it unsuitable for further use. It is recommended to fit felt pads to the furniture legs, this will avoid mechanical damage to the cork. Manufacturers do not recommend using rubber as pads, as it leaves indelible dark stains on the cork flooring. The same applies to carpets with a latex base; it is better to replace them with products made from natural materials. Cork floors with a vinyl decorative coating need to be treated with mastic once a year. By following these simple recommendations, you can enjoy cork floors in your home for many years.