Drywall was invented in the 19th century and has been around ever since.gains more authority in the construction materials market. Any fantasy can be realized when using it. A suspended ceiling made of plasterboard is one of the promising areas of application of this material. Suspended plasterboard ceilings have earned their placepopularity due to the variety of shapes and colors. Nowadays, most people prefer a variety of shapes in the interior of their home. Everyone wants everything around to be cozy and elegant. The ceiling is a large field for designers to experiment, and a plasterboard ceiling structure is a good tool in their hands.

Suspended plasterboard ceilings have earned their placepopularity due to the variety of shapes and colors. Nowadays, most people prefer a variety of shapes in the interior of their home. Everyone wants everything around to be cozy and elegant. The ceiling is a large field for designers to experiment, and a plasterboard ceiling structure is a good tool in their hands.

The construction of the ceiling from plasterboard

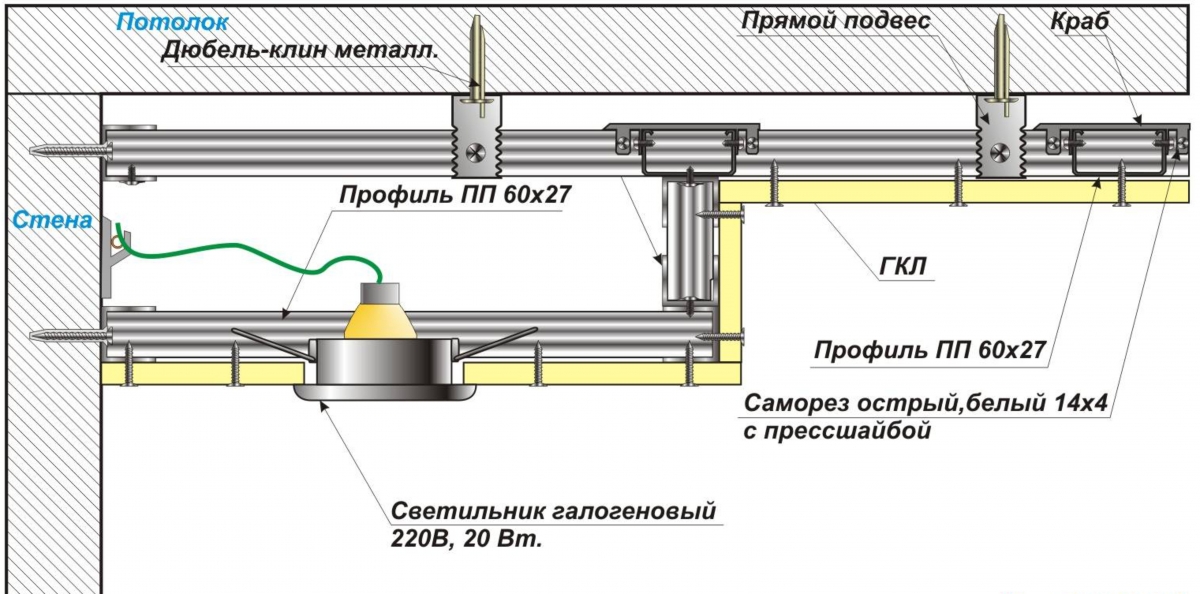

To install a suspended ceiling you will need:sheets of plasterboard. A suspended ceiling is a single- or multi-level flat structure made of plasterboard on a ceiling of any intended shape, fixed at a certain distance from the ceiling slab inside the room. The plane of such a ceiling is made of plasterboard sheets. Usually, sheets of plasterboard of the GKL type (ordinary) are used, 1.2 m wide, 2.5 or 3 m long, 6.9 or 12.5 mm thick. In rooms with high humidity (bathroom, toilet), it is recommended to use moisture-resistant plasterboard of the GKLV type. Plasterboard sheets are attached to metal profiles. Fastening to the wall is provided by guide profiles (U-shaped) of the PN28/27 brand. Plasterboard is suspended to the ceiling on ceiling profiles (C-shaped) of the PP60x27 brand through hangers. The connection of ceiling profiles is made with a crab fastener, the design of which allows them to be fastened in the form of a cross. Return to contents</a>

To install a suspended ceiling you will need:sheets of plasterboard. A suspended ceiling is a single- or multi-level flat structure made of plasterboard on a ceiling of any intended shape, fixed at a certain distance from the ceiling slab inside the room. The plane of such a ceiling is made of plasterboard sheets. Usually, sheets of plasterboard of the GKL type (ordinary) are used, 1.2 m wide, 2.5 or 3 m long, 6.9 or 12.5 mm thick. In rooms with high humidity (bathroom, toilet), it is recommended to use moisture-resistant plasterboard of the GKLV type. Plasterboard sheets are attached to metal profiles. Fastening to the wall is provided by guide profiles (U-shaped) of the PN28/27 brand. Plasterboard is suspended to the ceiling on ceiling profiles (C-shaped) of the PP60x27 brand through hangers. The connection of ceiling profiles is made with a crab fastener, the design of which allows them to be fastened in the form of a cross. Return to contents</a>

Marking for a suspended structure

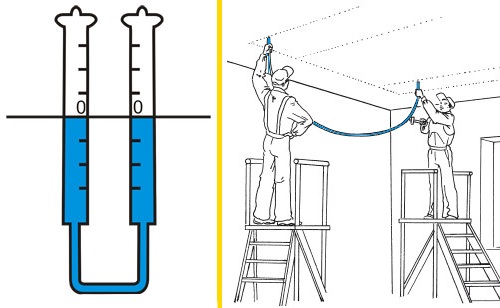

Scheme of marking the ceiling using waterlevel. To install a suspended ceiling, detailed marking of the walls and ceiling is required. First, the walls are marked for attaching the guide profiles. To do this, the actual ceiling height is specified - the height of the ceiling is almost always different in different points of the same room. Therefore, the wall height is determined using a tape measure at least in three points (at the corners and in the center of the wall). The first mark is made in the corner of the wall, where the height is the lowest. The mark is installed at a distance of 8-10 cm from the ceiling surface if built-in lighting or utility wiring is provided, and at a distance of 5-6 cm if they are not needed. A similar mark is made in the other corner of the wall, but taking into account the actual ceiling height. After installation, the suspended structure should be parallel to the floor. Between the marks along the wall, construction twine rubbed with dye is pulled. With its help, a line is applied (beaten off) between the marks. All walls are marked in the same order. The next stage of preparation involves marking the ceiling surface for installing the ceiling profiles. First, 30-35 cm away from the far wall, make marks, and use a painted cord to mark a line on the ceiling strictly parallel to the wall. The same is done on the opposite side of the room. Between these lines, parallel lines are drawn across the entire surface of the ceiling at a distance of 60-70 cm from each other. The distance between all lines should be the same across the entire surface. The same markings are made relative to the other two walls. As a result, a grid of lines (diagram) should be marked on the ceiling, which determines the direction of placement of the central line of the ceiling profiles. The points for installing ceiling fasteners (suspensions) are marked on the ceiling lines. To do this, points for holes are marked on all lines (along the entire length of the line) at a distance of 70-80 cm from each other. These points should not coincide with the intersection of lines on the ceiling - it is recommended that the points be located no closer than 10 cm from the intersection. Return to Contents</a>

Scheme of marking the ceiling using waterlevel. To install a suspended ceiling, detailed marking of the walls and ceiling is required. First, the walls are marked for attaching the guide profiles. To do this, the actual ceiling height is specified - the height of the ceiling is almost always different in different points of the same room. Therefore, the wall height is determined using a tape measure at least in three points (at the corners and in the center of the wall). The first mark is made in the corner of the wall, where the height is the lowest. The mark is installed at a distance of 8-10 cm from the ceiling surface if built-in lighting or utility wiring is provided, and at a distance of 5-6 cm if they are not needed. A similar mark is made in the other corner of the wall, but taking into account the actual ceiling height. After installation, the suspended structure should be parallel to the floor. Between the marks along the wall, construction twine rubbed with dye is pulled. With its help, a line is applied (beaten off) between the marks. All walls are marked in the same order. The next stage of preparation involves marking the ceiling surface for installing the ceiling profiles. First, 30-35 cm away from the far wall, make marks, and use a painted cord to mark a line on the ceiling strictly parallel to the wall. The same is done on the opposite side of the room. Between these lines, parallel lines are drawn across the entire surface of the ceiling at a distance of 60-70 cm from each other. The distance between all lines should be the same across the entire surface. The same markings are made relative to the other two walls. As a result, a grid of lines (diagram) should be marked on the ceiling, which determines the direction of placement of the central line of the ceiling profiles. The points for installing ceiling fasteners (suspensions) are marked on the ceiling lines. To do this, points for holes are marked on all lines (along the entire length of the line) at a distance of 70-80 cm from each other. These points should not coincide with the intersection of lines on the ceiling - it is recommended that the points be located no closer than 10 cm from the intersection. Return to Contents</a>

Mounting the skeleton of a false ceiling with your own hands

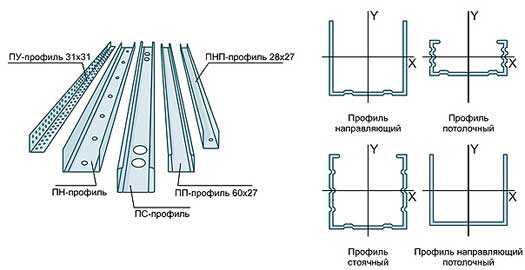

Profiles for plasterboard.The frame of a suspended plasterboard ceiling is a fastened structure made of profiles. First, the guides are fixed. They should be installed along the line drawn on the wall. U-shaped profiles usually have holes for installation on their base. If there are no holes, they must be drilled - first at a distance of 15-20 cm from the edge, then after 80-100 cm. The diameter of the hole is 6-7 mm. The profiles are applied to the wall one by one at the place of their installation, marks are made on the wall through the holes. At the marked points, holes with a diameter of about 8 mm are made with a hammer drill or an electric drill. Plastic dowels are installed in the holes. A sealing tape with an adhesive layer is glued to the outer surface of the guide profiles. The guides are installed on the wall so that there is a sealing tape between the profile and the wall, and are fastened with self-tapping screws. The elements are installed along the entire perimeter of the room. When installing them, it is necessary to monitor the horizontal position. If necessary, the alignment is done with thin spacers. The ceiling profiles are first mounted between two walls along the shorter wall. Their ends are fixed inside the U-shaped profile, with the base of the profile facing downwards. These profiles must be the same length. If there is no such length, the profiles are extended to the required size and firmly fastened with a metal strip. The location of the ceiling profiles is strictly controlled by the lines on the ceiling - the central line must coincide with the line on the ceiling. The profiles are placed parallel along the entire length of the ceiling.

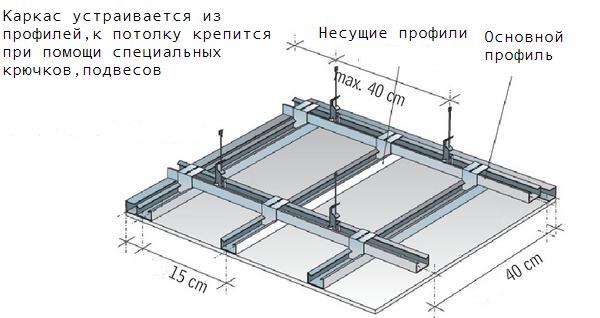

Profiles for plasterboard.The frame of a suspended plasterboard ceiling is a fastened structure made of profiles. First, the guides are fixed. They should be installed along the line drawn on the wall. U-shaped profiles usually have holes for installation on their base. If there are no holes, they must be drilled - first at a distance of 15-20 cm from the edge, then after 80-100 cm. The diameter of the hole is 6-7 mm. The profiles are applied to the wall one by one at the place of their installation, marks are made on the wall through the holes. At the marked points, holes with a diameter of about 8 mm are made with a hammer drill or an electric drill. Plastic dowels are installed in the holes. A sealing tape with an adhesive layer is glued to the outer surface of the guide profiles. The guides are installed on the wall so that there is a sealing tape between the profile and the wall, and are fastened with self-tapping screws. The elements are installed along the entire perimeter of the room. When installing them, it is necessary to monitor the horizontal position. If necessary, the alignment is done with thin spacers. The ceiling profiles are first mounted between two walls along the shorter wall. Their ends are fixed inside the U-shaped profile, with the base of the profile facing downwards. These profiles must be the same length. If there is no such length, the profiles are extended to the required size and firmly fastened with a metal strip. The location of the ceiling profiles is strictly controlled by the lines on the ceiling - the central line must coincide with the line on the ceiling. The profiles are placed parallel along the entire length of the ceiling. Frame diagram for suspended ceiling.Ceiling profiles for transverse installation are cut into sections of the length measured between the wall and the first installed profile and between two adjacent ones. These sections are installed strictly according to the markings on the ceiling. The first sections are fastened with one end inside the guide profile, and all the others are fastened to the already installed longitudinal profiles using a cross-shaped crab fastener. The fastener allows you to securely fasten the connection in the form of a cross. Fastening of ceiling profiles to the ceiling is carried out using hangers. For this purpose, dowels are installed in the holes in the ceiling. The hanger strips are bent as follows. The side parts of the strip with holes are bent from the solid part at an angle of 90°, forming a U-shaped profile. The ends of the side posts are bent at a right angle to the sides. The height of the hanger post must strictly correspond to the distance between the ceiling profile and the surface of the ceiling. The upper platform of the hanger is fixed in the dowel with a self-tapping screw. The legs of the suspension are fixed to the ceiling profile. The suspensions are also fixed at all points of the marked mounting scheme. This completes the installation of the frame structure. Return to the table of contents</a>

Frame diagram for suspended ceiling.Ceiling profiles for transverse installation are cut into sections of the length measured between the wall and the first installed profile and between two adjacent ones. These sections are installed strictly according to the markings on the ceiling. The first sections are fastened with one end inside the guide profile, and all the others are fastened to the already installed longitudinal profiles using a cross-shaped crab fastener. The fastener allows you to securely fasten the connection in the form of a cross. Fastening of ceiling profiles to the ceiling is carried out using hangers. For this purpose, dowels are installed in the holes in the ceiling. The hanger strips are bent as follows. The side parts of the strip with holes are bent from the solid part at an angle of 90°, forming a U-shaped profile. The ends of the side posts are bent at a right angle to the sides. The height of the hanger post must strictly correspond to the distance between the ceiling profile and the surface of the ceiling. The upper platform of the hanger is fixed in the dowel with a self-tapping screw. The legs of the suspension are fixed to the ceiling profile. The suspensions are also fixed at all points of the marked mounting scheme. This completes the installation of the frame structure. Return to the table of contents</a>

Preparation of plasterboard

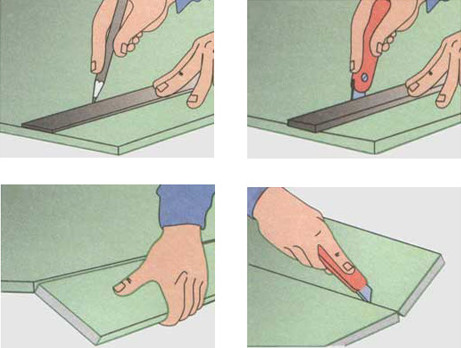

Scheme of cutting drywall using a knife.Preparation and cutting of plasterboard is carried out on the floor. To do this, it is necessary to lay out the sheets completely and cut them. The first sheet is usually laid completely without cutting. Further laying requires the necessary cutting and cutting of sheets of the required size. The easiest way to cut plasterboard is with a knife. The sheet is laid on a horizontal flat surface, a line is drawn according to the marking. The cardboard is cut along the line with a knife. The sheet is installed so that the cut line is on the border of the table, and is bent. Then the sheet is turned over and cut along the bend line with a knife. All curly bends are cut with a hacksaw for metal. Openings inside the sheet (for example, for lamps) are cut with a jigsaw. At the ends of the plasterboard sheets, the upper chamfer is removed with a knife or a file. Return to the table of contents</a>

Scheme of cutting drywall using a knife.Preparation and cutting of plasterboard is carried out on the floor. To do this, it is necessary to lay out the sheets completely and cut them. The first sheet is usually laid completely without cutting. Further laying requires the necessary cutting and cutting of sheets of the required size. The easiest way to cut plasterboard is with a knife. The sheet is laid on a horizontal flat surface, a line is drawn according to the marking. The cardboard is cut along the line with a knife. The sheet is installed so that the cut line is on the border of the table, and is bent. Then the sheet is turned over and cut along the bend line with a knife. All curly bends are cut with a hacksaw for metal. Openings inside the sheet (for example, for lamps) are cut with a jigsaw. At the ends of the plasterboard sheets, the upper chamfer is removed with a knife or a file. Return to the table of contents</a>

Installation of plasterboard construction

Scheme of suspended ceiling made of plasterboard.Before assembling the entire suspended plasterboard ceiling structure, it is necessary to conduct all communications. First of all, the electrical wiring is carried out. They are collected in a bundle, which is placed in a corrugated hose. Wires are brought to the place of installation of built-in lamps. The entire electrical circuit is carefully distributed along the frame and secured. The plasterboard structure, assembled on the floor, is alternately raised up and secured to the profiles using self-tapping screws. A hole for a screw is drilled in the plasterboard at the attachment points. Fastening of the structure begins with a whole sheet, which is attached to the corner of the ceiling. The distance between the fasteners should be 10-15 cm. The screws should be tightened so that their heads do not protrude above the surface of the sheet. The gap between the plasterboard sheets should not exceed 2 mm. During installation, it is necessary to ensure that the chamfer on the ends is on the outer surface in the area of the joint of the sheets. Complete installation of a suspended plasterboard ceiling is completed with puttying and sanding the surface. First, a special putty mixture is applied to the joints of the sheets so that it fills the space formed by the chamfer. A thin layer of putty is applied in places where screws are screwed in. After the mixture dries, the primary surface cleaning is performed. Then a thin layer of finishing putty mixture of liquid consistency is applied to the entire surface. The mixture dries within 1-2 days. After this, the entire surface of the plasterboard is carefully rubbed and sanded with a sanding mesh. Return to contents</a>

Scheme of suspended ceiling made of plasterboard.Before assembling the entire suspended plasterboard ceiling structure, it is necessary to conduct all communications. First of all, the electrical wiring is carried out. They are collected in a bundle, which is placed in a corrugated hose. Wires are brought to the place of installation of built-in lamps. The entire electrical circuit is carefully distributed along the frame and secured. The plasterboard structure, assembled on the floor, is alternately raised up and secured to the profiles using self-tapping screws. A hole for a screw is drilled in the plasterboard at the attachment points. Fastening of the structure begins with a whole sheet, which is attached to the corner of the ceiling. The distance between the fasteners should be 10-15 cm. The screws should be tightened so that their heads do not protrude above the surface of the sheet. The gap between the plasterboard sheets should not exceed 2 mm. During installation, it is necessary to ensure that the chamfer on the ends is on the outer surface in the area of the joint of the sheets. Complete installation of a suspended plasterboard ceiling is completed with puttying and sanding the surface. First, a special putty mixture is applied to the joints of the sheets so that it fills the space formed by the chamfer. A thin layer of putty is applied in places where screws are screwed in. After the mixture dries, the primary surface cleaning is performed. Then a thin layer of finishing putty mixture of liquid consistency is applied to the entire surface. The mixture dries within 1-2 days. After this, the entire surface of the plasterboard is carefully rubbed and sanded with a sanding mesh. Return to contents</a>

Required Tools

You will need the following tool: Tools for installing plasterboard on the ceiling.

Tools for installing plasterboard on the ceiling.

- perforator;

- Bulgarian;

- electric drill;

- jig saw electric;

- Screwdriver;

- grinding machine;

- grid grinding;

- a hammer;

- chisel;

- pliers;

- knife;

- hacksaw for metal;

- scissors for metal;

- screwdriver;

- bit;

- level;

- plumb bob;

- roulette;

- line meter.

The use of plasterboard in the construction of suspendedceiling allows you to provide the desired design of the apartment. The ease of processing the material leads to the fact that the installation of a suspended ceiling can be done independently and with minimal costs. With a little imagination, it is enough to simply do .