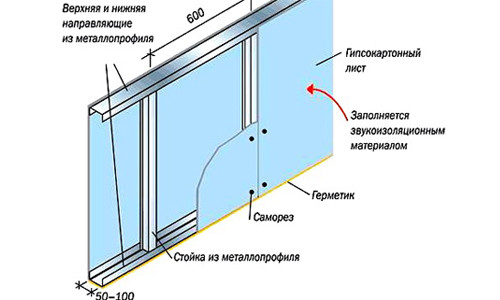

When remodeling a room or something elseAt the stage of the main construction, there is a need to divide the internal space. A simple, fast and effective way to solve this problem is to build walls from plasterboard. In this case, walls mean internal partitions. Plasterboard wall diagram.

Plasterboard wall diagram.

Scope and main dimensions of drywall

The structure of a gypsum plasterboard sheet (GKL) is a construction consisting of several layers:

- outer layers - regular cardboard or cardboard impregnated with special additives that give certain properties to the material (water-repellent or fire-resistant);

- the inner layer is made of gypsum-containing material, the thickness of the layer determines the structural strength and purpose of the sheet.

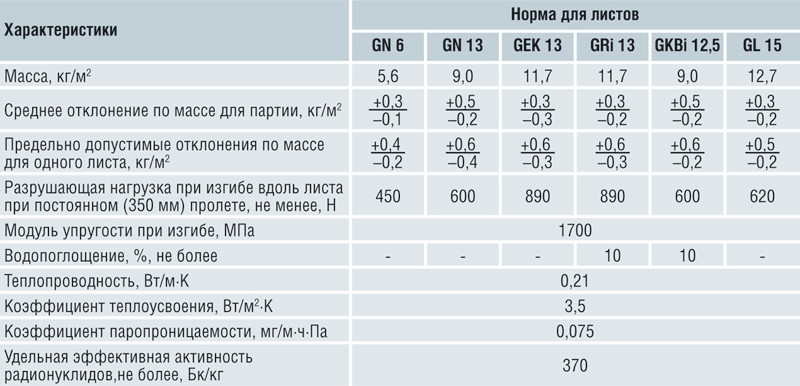

The main area of application of plasterboardis the construction of partitions, suspended ceilings, interior wall paneling. Sheets of small thickness can be deformed in a certain way and used to create curvilinear planes and structures. Physical and technical characteristicsgypsum plasterboard sheets. Manufacturers produce standard-sized material that fits comfortably into the dimensions of residential and industrial premises. The most common sheet is 1200 x 2500 mm. Depending on the purpose (ceiling or wall), its thickness can vary from 6.5 to 15 mm. For ease of use, one or two longitudinal edges of the sheet are formed into a strip, the thickness of which is less than the thickness of the main sheet. The presence of such a chamfer makes it easier to join and finish the sheets later. The joints of the sheets are glued with serpyanka tape and covered with a layer of putty. Return to contents</a>

Physical and technical characteristicsgypsum plasterboard sheets. Manufacturers produce standard-sized material that fits comfortably into the dimensions of residential and industrial premises. The most common sheet is 1200 x 2500 mm. Depending on the purpose (ceiling or wall), its thickness can vary from 6.5 to 15 mm. For ease of use, one or two longitudinal edges of the sheet are formed into a strip, the thickness of which is less than the thickness of the main sheet. The presence of such a chamfer makes it easier to join and finish the sheets later. The joints of the sheets are glued with serpyanka tape and covered with a layer of putty. Return to contents</a>

Main types of profiles used

The basis (frame) of plasterboard walls is made up of metal profiles and guides. According to their functional purpose, the following types of profiles are distinguished:

Depending on the overall dimensions, there are two main types of profiles: Types of profiles for plasterboard.

Types of profiles for plasterboard.

- D-type - used to form the surface for fastening sheets when cladding walls and constructing boxes and suspended ceilings;

- W-type is used to make a frame when constructing walls from plasterboard.

In turn, according to the size of the frame profiledistinguish 50, 75 and 100 mm in width. That is, the marking of profiled moldings used during installation consists of two Latin letters. The first letter describes the area of functional purpose. The second characterizes the dimensions of the product. Additionally, auxiliary fastening and connecting elements can be used:

- direct hanger - U-shaped bracket for fixing profiles to the enclosing surface;

- crab - to ensure perpendicular connection of individual elements;

- connector - for connecting individual sections of the profile along the length.

Basically, in the process of work you can get by with itwithout using standard fasteners. They can be successfully replaced by small sections of support and guide profiles, cut and fastened accordingly to the supporting frame. Return to contents</a>

Tools and materials

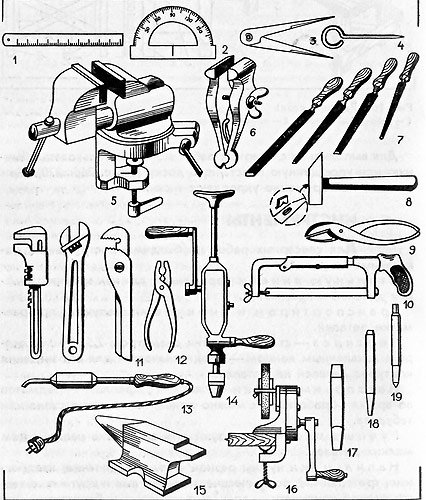

A set of tools for working with plasterboard. In order to build a plasterboard structure, you will need the following tools:

A set of tools for working with plasterboard. In order to build a plasterboard structure, you will need the following tools:

- the hammer drill drills holes for fastening guide profiles;

- drill or screwdriver with a suitable attachment for fastening the frame members to each other with the help of self-tapping screws for metal;

- measuring tool - tape measure, square, level;

- metal shears - for cutting profiles;

- a construction knife and a hacksaw are necessary when cutting sheet material.

For final preparation for finishing of the finished wall, you may additionally need:

- tape-serpyanka for sealing inter-sheet joints;

- metal corners for the decoration of external corners of walls from plasterboard.

Connection of metal frame elements betweenis carried out using self-tapping screws for metal with a tip made in the form of a drill. Craftsmen sometimes call them fleas or seeds. The sheets of gypsum board are attached to the frame using self-tapping screws with a piercing tip and a countersunk head, which is screwed into the gypsum massif without preliminary drilling. The construction of the internal partition begins with the manufacture of a frame from metal profiles CW and UW. Return to the table of contents</a>

Installation of guide profiles: tips

Scheme of fastening of metal frame underplasterboard. According to the preliminary design, installation lines are marked on the surface of the floor, walls and ceiling. If the design provides for the construction of a wall with a doorway, the preliminary marking must take it into account. Mutual perpendicularity of the lines is a mandatory condition. Errors at this stage will result in the wall deviating from the vertical position or shifting horizontally. The vertical position of the marking lines is checked with a building level or a plumb line. The perpendicularity of the horizontal marking relative to the walls is checked with a square. The guides of the appropriate length are measured and cut. The resulting segments must be secured along the marking lines to create attachment points for the support profiles. The fastening technology will differ slightly depending on the surface material. The simplest material in technological terms is wood. In this case, it is enough to drill through the base of the profile with a self-tapping screw of the appropriate length. Gypsum or foam concrete blocks also generally allow direct drilling. For a more durable fastening, it is necessary to use dowels and screws. Nowadays, fastening with dowel-nails is more common as a more technologically advanced method. If necessary, additional mounting holes are drilled in the base of the profile. Then it is placed against the marking line, and the position of the mounting hole is transferred to the wall with a pencil. Using a hammer drill with a drill of the appropriate diameter, holes of the required depth are drilled. It is very convenient to control the depth of the hole using a strip of masking tape folded in several layers, previously fixed to the surface of the drill. The length of the drill, limited by the tape, should match or be slightly longer than the length of the dowel. Such a simple device, unlike a standard depth gauge, is more convenient to use and does not interfere with use in hard-to-reach places. Dowel-nails are inserted into the mounting holes and, using a hammer and punch, are driven into the holes in the enclosing surfaces. Brick and concrete require the use of dowel-nails for fastening the profile. When installing, do not forget to stick a special vibration tape to the base of the guide. This will improve the soundproofing properties of the plasterboard wall, preventing the transmission of sound from the load-bearing walls. Return to contents</a>

Scheme of fastening of metal frame underplasterboard. According to the preliminary design, installation lines are marked on the surface of the floor, walls and ceiling. If the design provides for the construction of a wall with a doorway, the preliminary marking must take it into account. Mutual perpendicularity of the lines is a mandatory condition. Errors at this stage will result in the wall deviating from the vertical position or shifting horizontally. The vertical position of the marking lines is checked with a building level or a plumb line. The perpendicularity of the horizontal marking relative to the walls is checked with a square. The guides of the appropriate length are measured and cut. The resulting segments must be secured along the marking lines to create attachment points for the support profiles. The fastening technology will differ slightly depending on the surface material. The simplest material in technological terms is wood. In this case, it is enough to drill through the base of the profile with a self-tapping screw of the appropriate length. Gypsum or foam concrete blocks also generally allow direct drilling. For a more durable fastening, it is necessary to use dowels and screws. Nowadays, fastening with dowel-nails is more common as a more technologically advanced method. If necessary, additional mounting holes are drilled in the base of the profile. Then it is placed against the marking line, and the position of the mounting hole is transferred to the wall with a pencil. Using a hammer drill with a drill of the appropriate diameter, holes of the required depth are drilled. It is very convenient to control the depth of the hole using a strip of masking tape folded in several layers, previously fixed to the surface of the drill. The length of the drill, limited by the tape, should match or be slightly longer than the length of the dowel. Such a simple device, unlike a standard depth gauge, is more convenient to use and does not interfere with use in hard-to-reach places. Dowel-nails are inserted into the mounting holes and, using a hammer and punch, are driven into the holes in the enclosing surfaces. Brick and concrete require the use of dowel-nails for fastening the profile. When installing, do not forget to stick a special vibration tape to the base of the guide. This will improve the soundproofing properties of the plasterboard wall, preventing the transmission of sound from the load-bearing walls. Return to contents</a>

Mounting of support profiles

Scheme of plasterboard joint filling.At the initial stage, the vertical support profiles are cut to the required size and installed. If necessary, individual segments can be joined to obtain the required length using auxiliary elements. The step of their installation should be a multiple of 600 mm, if possible. With a sheet width of 1200 mm, the plasterboard sheet will be fixed on three profiles, which ensures sufficient spatial rigidity of the structure. When forming a doorway, the profiles are placed with the base inside the opening. Additionally, wooden blocks of a suitable size are inserted inside for reinforcement. Subsequently, the door frame will be attached to them with self-tapping screws. Additionally, a plasterboard wall can be reinforced by placing blocks inside the support posts. The need for additional reinforcement arises if heavy shelves or wall cabinets are supposed to be attached to the wall in advance. If the height of the room exceeds the length of the plasterboard sheet, it is necessary to install additional cross mounting posts. They are made of the same material as the vertical supports. Horizontal lintels are installed at random heights. The joint line between the sheets will not be continuous. In other words, first the partition is installed so that the whole sheet is installed from the floor, the next one is installed taking into account the fastening of the sheet from the ceiling. Electrical wiring is usually hidden inside such a wall, in some cases water and sewer pipes are brought in. To impart heat and sound insulation properties, the internal space formed by the racks covered with gypsum board sheets is filled with mineral mats based on basalt fiber. Return to contents</a>

Scheme of plasterboard joint filling.At the initial stage, the vertical support profiles are cut to the required size and installed. If necessary, individual segments can be joined to obtain the required length using auxiliary elements. The step of their installation should be a multiple of 600 mm, if possible. With a sheet width of 1200 mm, the plasterboard sheet will be fixed on three profiles, which ensures sufficient spatial rigidity of the structure. When forming a doorway, the profiles are placed with the base inside the opening. Additionally, wooden blocks of a suitable size are inserted inside for reinforcement. Subsequently, the door frame will be attached to them with self-tapping screws. Additionally, a plasterboard wall can be reinforced by placing blocks inside the support posts. The need for additional reinforcement arises if heavy shelves or wall cabinets are supposed to be attached to the wall in advance. If the height of the room exceeds the length of the plasterboard sheet, it is necessary to install additional cross mounting posts. They are made of the same material as the vertical supports. Horizontal lintels are installed at random heights. The joint line between the sheets will not be continuous. In other words, first the partition is installed so that the whole sheet is installed from the floor, the next one is installed taking into account the fastening of the sheet from the ceiling. Electrical wiring is usually hidden inside such a wall, in some cases water and sewer pipes are brought in. To impart heat and sound insulation properties, the internal space formed by the racks covered with gypsum board sheets is filled with mineral mats based on basalt fiber. Return to contents</a>

Installation of plasterboard sheets

Finally, the partition is formed as a wall by lining the plasterboard sheets on both sides. When installing the sheets, several mandatory conditions must be observed:

- Between the edges of the sheets and the enclosing surfaces it is necessary to leave a compensation gap of 5-10 mm;

- compensation gap between the sheets should be 2-3 mm;

- The mounting of the sheets should be carried out in an unrestricted manner, avoiding the formation of coincident horizontal joints;

- The joints of the sheets must fall on the middle of the profiles;

- A sheet of plasterboard should be fixed around the perimeter.

Before final finishing, it is necessary to carry out a number of additional operations:

- sealing of compensation gaps;

- sealing joints sheets;

- forming, if necessary, with the help of metal corners of the outer corners of the walls.

Carrying out operations on installation of elementsfastenings and their subsequent cladding, taking into account all requirements, will allow you to build a wall from plasterboard, ready for finishing work and meeting the most stringent requirements.