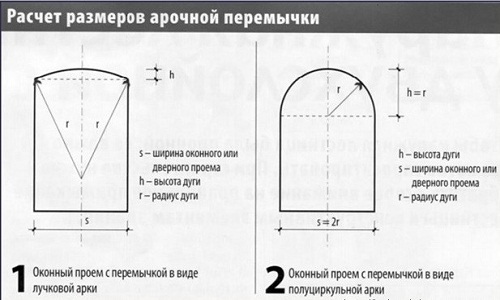

When replacing a door or arranging an opening in the form ofarches may require expansion. If a lightweight partition between rooms is being reconstructed, the plasterboard or similar material it is made of can be cut and sawed as desired. This will not affect the strength of the building. Load-bearing walls are a different matter, damage to which can lead to irreparable consequences. Any reconstruction of them must be carried out in accordance with a separate project containing a calculation of the redistribution of the load after changes have been made. Calculation of the dimensions of the arched lintel.

Calculation of the dimensions of the arched lintel.

With what to begin dismantling?

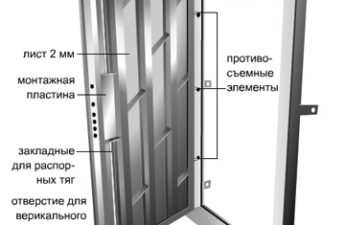

First, it is necessary to strengthen the openingsin load-bearing walls. In concrete buildings, it can be done after the work is completed, but a brick structure must be taken care of at the very beginning to prevent its destruction. For this, a metal beam is installed at the top, for which a niche is sawn in the masonry. Its depth is approximately half a brick. All voids above and below the beam are filled with concrete mixture. The following materials and tools are used in the preparatory work and directly for increasing the opening: Scheme of insulation and reinforcement of a wooden door.

Scheme of insulation and reinforcement of a wooden door.

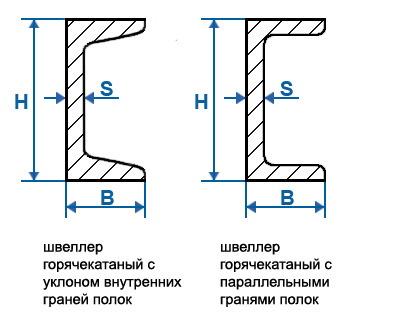

- The steel channel (beam with a cross-section in the form of the letter "P");

- bolts tightening 20 mm or metal pins 16 mm in diameter;

- steel plates (sheet steel);

- metal corner;

- Cement mortar;

- electric drill;

- electric cutter, benzorez or Bulgarian with a diamond circle;

- jacks or other supports for the duration of the work;

- perforator (only for bricks).

Holes are drilled in advance in the channels fortie bolts, at least 3 pieces. The distance between them should be at least 50 cm. The length of the channel is selected so that it enters 25-35 cm into the brick walls on both sides of the opening. The required cross-section of the beam used, as well as the class of metal from which it should be made, are determined during load calculations and included in the redevelopment project. Return to contents</a>

How to strengthen the structure?

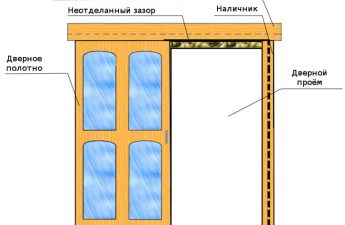

Door frame design diagram.Brick structures require a particularly careful approach. In a pre-cut niche, before widening the opening, it is necessary to fix a channel (best of all, with cement mortar). The wall is drilled through the holes in it. Then, on the opposite side, a second channel with holes is installed in the same way. The beams are tied together with tie bolts or studs with washers and nuts on both sides. Further work can only be done after the mortar has completely hardened. To prevent the brick from collapsing from above, the channels are connected along the lower shelves, for which steel plates 5-6 mm thick are welded to them. Their pitch should be approximately equal to the pitch of the tie bolts. If the new width of the openings in brick walls exceeds 1.5 m, they should be reinforced with vertical posts. They are also made of steel strips, which are welded to the lower shelves of the channels. The vertical posts, in turn, need to be connected to each other with transverse plates inside the opening. The most reliable design is considered to be one consisting of two welded frames. The frames can be made from channels. They are placed on both sides of the opening, and then pulled together through the load-bearing walls with studs. This method of reinforcement is the most expensive, so it should only be used in the case of widening the opening to a greater height. It can also be recommended for heavy loads, especially on the lower floors of multi-story buildings. Return to contents</a>

Door frame design diagram.Brick structures require a particularly careful approach. In a pre-cut niche, before widening the opening, it is necessary to fix a channel (best of all, with cement mortar). The wall is drilled through the holes in it. Then, on the opposite side, a second channel with holes is installed in the same way. The beams are tied together with tie bolts or studs with washers and nuts on both sides. Further work can only be done after the mortar has completely hardened. To prevent the brick from collapsing from above, the channels are connected along the lower shelves, for which steel plates 5-6 mm thick are welded to them. Their pitch should be approximately equal to the pitch of the tie bolts. If the new width of the openings in brick walls exceeds 1.5 m, they should be reinforced with vertical posts. They are also made of steel strips, which are welded to the lower shelves of the channels. The vertical posts, in turn, need to be connected to each other with transverse plates inside the opening. The most reliable design is considered to be one consisting of two welded frames. The frames can be made from channels. They are placed on both sides of the opening, and then pulled together through the load-bearing walls with studs. This method of reinforcement is the most expensive, so it should only be used in the case of widening the opening to a greater height. It can also be recommended for heavy loads, especially on the lower floors of multi-story buildings. Return to contents</a>

Features of dismantling of concrete and brick walls

Diagram of a channel for strengthening an opening.The cuts should be made according to the previously made markings. Both the hand-held electric cutter and the petrol cutter are equipped with a diamond wheel, sufficient for a cutting depth of up to 10 cm. These tools provide constant wetting during operation, which minimizes dust formation. Since capital partitions, especially brick ones, can be quite massive, openings in load-bearing walls are cut from both sides. Naturally, the previously installed reinforcing beam should not be damaged. If the wall is so thick that it is impossible to make a through cut even from both sides, the remains of the brickwork can be knocked down with a hammer drill. There is also a more effective mechanism - a ring cutter, providing a cutting depth of up to 26 cm, but its price is very high. However, thick brick walls have their advantages. It is not necessary to frame the opening in them. It is enough to cover it with cement mortar, and install the door frame as quickly as possible. Concrete is cut in small rectangular or square pieces. It is desirable that their weight does not exceed 50 kg. It is necessary to take care of respiratory protection from dust, the occurrence of which cannot be avoided even when working with professional tools. Especially a lot of it is formed if you try to expand a concrete opening with an ordinary "grinder" with a diamond wheel. To remove dust in a timely manner, you can adapt a vacuum cleaner by placing its hose near the area being processed. In no case should you use a hammer drill or jackhammer to break through concrete. Strong vibration causes resonant vibrations in its thickness. This, in turn, disrupts the connection between the concrete and the reinforcement, leads to the occurrence of microcracks and, as a result, greatly weakens the building structure. If the reinforcing beam was not installed before starting work, it is necessary to use temporary supports or jacks, which are then removed. After expanding the opening in the concrete wall, it is reinforced with channels or a metal corner along the perimeter.

Diagram of a channel for strengthening an opening.The cuts should be made according to the previously made markings. Both the hand-held electric cutter and the petrol cutter are equipped with a diamond wheel, sufficient for a cutting depth of up to 10 cm. These tools provide constant wetting during operation, which minimizes dust formation. Since capital partitions, especially brick ones, can be quite massive, openings in load-bearing walls are cut from both sides. Naturally, the previously installed reinforcing beam should not be damaged. If the wall is so thick that it is impossible to make a through cut even from both sides, the remains of the brickwork can be knocked down with a hammer drill. There is also a more effective mechanism - a ring cutter, providing a cutting depth of up to 26 cm, but its price is very high. However, thick brick walls have their advantages. It is not necessary to frame the opening in them. It is enough to cover it with cement mortar, and install the door frame as quickly as possible. Concrete is cut in small rectangular or square pieces. It is desirable that their weight does not exceed 50 kg. It is necessary to take care of respiratory protection from dust, the occurrence of which cannot be avoided even when working with professional tools. Especially a lot of it is formed if you try to expand a concrete opening with an ordinary "grinder" with a diamond wheel. To remove dust in a timely manner, you can adapt a vacuum cleaner by placing its hose near the area being processed. In no case should you use a hammer drill or jackhammer to break through concrete. Strong vibration causes resonant vibrations in its thickness. This, in turn, disrupts the connection between the concrete and the reinforcement, leads to the occurrence of microcracks and, as a result, greatly weakens the building structure. If the reinforcing beam was not installed before starting work, it is necessary to use temporary supports or jacks, which are then removed. After expanding the opening in the concrete wall, it is reinforced with channels or a metal corner along the perimeter.