Finishing walls with gypsum fiber sheets -one of the popular methods of cladding. This method has its advantages due to a number of reasons. There are simple and moisture-resistant gypsum fiber boards. This material performs the same function as plasterboard, but it is more durable and therefore more expensive. Scheme of fastening gypsum fiber sheets with glue. In addition, this material has many more positive qualities:

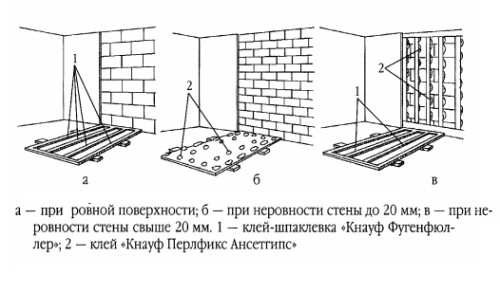

Scheme of fastening gypsum fiber sheets with glue. In addition, this material has many more positive qualities:

- security;

- resistance to scratches;

- good water resistance;

- no need for a special tool for fixing the material;

- the ability to disguise communications, hide wall defects;

- the possibility of partitioning.

The slabs are available in different sizes, which is very convenient for installation on walls in the kitchen, bathroom, toilet using the frameless installation method (then the walls are puttied with a special moisture-resistant compound).

Wall finishing with the use of Glu: mounting options

Do-it-yourself gypsum fiberboard wall cladding is performed using the following tools and materials: Tools for gypsum fiber board installation.

Tools for gypsum fiber board installation.

- gvl in the right amount;

- self-tapping screws, nails;

- electric jigsaw or saw with large teeth (for cutting gwls);

- putty, primer;

- special glue;

- glass wool;

- metal profile or wooden slats;

- level, plumb bob;

- roulette;

- brackets;

- mallet;

- notched trowel;

- rope.

Before installation, gypsum fiber board must be carefully removed fromwalls old coating. Remove all peeling parts and eliminate gaps between several concrete slabs. Finishing with this material can be done in 2 ways: frameless and frame. The first option involves gluing the material to the surface, in the second case, it is necessary to install a frame to which the slabs are attached. Return to contents</a>

Frameless method of decoration

This method is good for walls with small irregularities. However, there are some installation features:

Rules for installation using the frameless method: Scheme of gypsum fiber board cladding on a wooden frame.

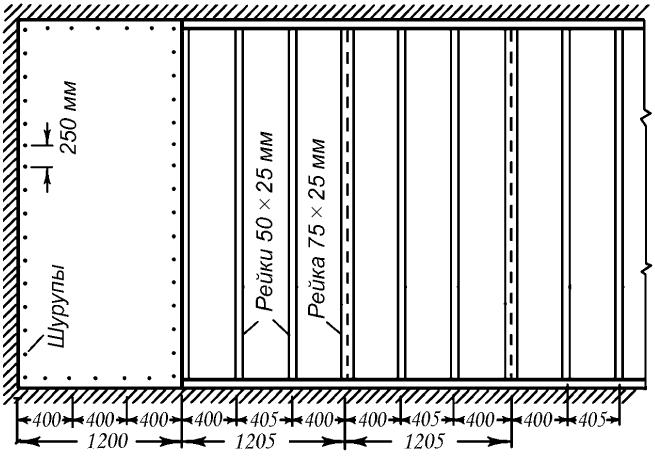

Scheme of gypsum fiber board cladding on a wooden frame.

To achieve a completely flat surface,After completing the installation, you need to fill all the joints and nail fixings. After waiting for the composition to dry, you can begin the subsequent finishing. Return to the table of contents</a>

Skeleton way of laying

With this type of installation, the fasteningis performed on metal or wooden profiles. For laying on the floor and ceiling, wooden slats must have a minimum cross-section of 30x50 mm. The slats are fastened with screws. The vertical posts must have a cross-section of 25x75 mm. It is necessary to observe the step of the posts, which should not be more than the width of one plate, preferably 400-405 mm. The plates are fixed to the frame with self-tapping screws with a step of 250 mm (if the sheet width is 1200-1205 mm). Glass wool is used to insulate the space between the posts. During installation, the following rules must be observed:

The use of a metal frame is more reliable. Galvanized metal profiles with a thickness of 0.56-0.6 mm are used. The installation looks like this:

Once the installation is complete, the surface needs to be puttied.slabs, carefully processing the joints between them and the attachment points. You can use regular putty. Subsequently, you can cover the slabs with any finishing material. You can easily install gypsum fiber sheets yourself. The installation method you choose depends on the quality and evenness of the walls (how pronounced the curvature is). Sometimes it is enough to just putty the walls. In other cases, you may need to use a frame. In any case, it is necessary to follow the sequence and rules for installing the material.