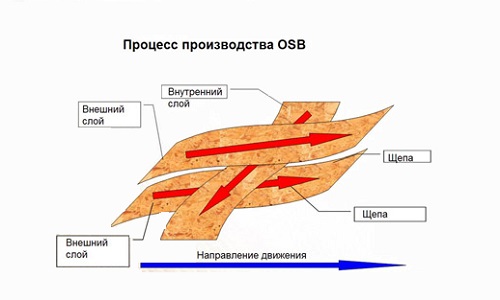

OSB boards are a modern universal building material, best suited for external and internal finishing of walls of residential or industrial premises. The process of manufacturing OSB boards.The material is made of resin and pressed wood chips. It is in great demand today due to its many positive properties: strength, durability, environmental friendliness, moisture resistance, ease of use, etc. Such panels from German, Swiss, Austrian, Canadian manufacturers have proven themselves well. It is necessary to consider in more detail the entire process of interior wall finishing with OSB.

The process of manufacturing OSB boards.The material is made of resin and pressed wood chips. It is in great demand today due to its many positive properties: strength, durability, environmental friendliness, moisture resistance, ease of use, etc. Such panels from German, Swiss, Austrian, Canadian manufacturers have proven themselves well. It is necessary to consider in more detail the entire process of interior wall finishing with OSB.

Preparatory work before installing osb boards

Before finishing the walls with OSB, it is necessary to carry out careful preparatory work. It consists of:

- in the selection of materials and tools;

- in the installation of the crate.

For preparatory and main work you will need the following materials and tools: To work with OSB boards you will need a jigsaw, a screwdriver, spatulas, and a brush.

To work with OSB boards you will need a jigsaw, a screwdriver, spatulas, and a brush.

- wooden beams 4x4 cm;

- plates osb thickness of 1.2 cm;

- Screwdriver;

- self-tapping screws;

- thermal insulator - mineral wool;

- antiseptic agent against decay;

- electric jigsaw;

- water-based primer;

- brush;

- putty;

- spatulas;

- varnish or paint for finishing.

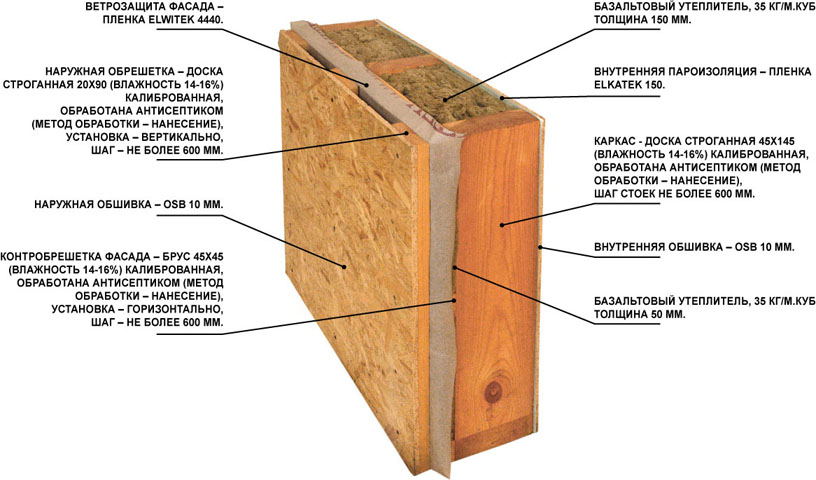

A few words should be said about the method usedmaterial - OSB boards. Their other name is oriented strand boards. Wood chips inside the material are arranged in 3 rows, each of them perpendicular to each other. This provides the material with high strength. Another important property is water resistance, which depends on the binder. Recently, it has become more environmentally friendly due to the use of resins. OSB panels are devoid of the disadvantages of their predecessors - chipboard, plywood, which must be treated with special anti-rot agents before installation. Panels specially sanded by the manufacturer have a more aesthetically attractive appearance. The panels can be fastened using self-tapping screws, dowels, nails. Preference is given to self-tapping screws when installing boards, since the reliability of fastening increases sharply, much fewer of them will be required for work than, for example, nails, if necessary, they can be unscrewed back. Now it is necessary to install a lathing of wooden beams on the walls, using a screwdriver and self-tapping screws. The distance between the supports should be approximately 40-50 cm. Such work usually does not cause any difficulties. If it is necessary to insulate the walls, then before the main work begins, after installing the lathing, mineral wool sheets are laid out. After the preparatory work has been carried out, the walls are finished with OSB boards. Return to the table of contents</a>

Interior decoration of the walls of the room with panels osb

Wall finished with OSB board.Finishing walls with OSB boards is similar to installing plasterboard sheets. It should only be taken into account that OSB boards weigh significantly more than plasterboard sheets, so they require more reliable fastening. The panels can be installed in 2 positions:

Wall finished with OSB board.Finishing walls with OSB boards is similar to installing plasterboard sheets. It should only be taken into account that OSB boards weigh significantly more than plasterboard sheets, so they require more reliable fastening. The panels can be installed in 2 positions:

- vertical;

- horizontal.

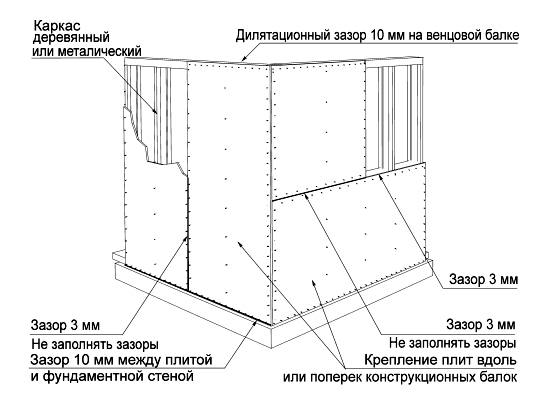

When producing finishing panels near doors andsmall gaps of about 3 mm must be left between window openings. It is best to use panels with tongue and groove edges for work, in this case there will be an additional “groove-tenon” connection, which will ensure a perfectly flat surface of the walls. Self-tapping screws for wood are screwed in with a screwdriver at a distance of about 15 cm from each other, retreating from the edge of the boards at least 1 cm. If necessary, adjusting to the required dimensions, you can cut the panels with a jigsaw. After the fastening has been made, it is necessary to finish the walls from OSB. It should be noted that here we are considering boards already sanded by the manufacturer, but if not, you need to sand their surface yourself using fine-grained sandpaper. Technique for installing OSB on a wall.The most common way to finish OSB panels is to putty them, which can be used to remove all the cracks that are present at the joints. The putty can be acrylic, latex, or gypsum-based. It is best if the putty is colorless. Before puttying the walls, they must be primed. Further finishing of the walls can consist of painting or varnishing. Experts recommend that if varnishing the walls is chosen, use matte varnish. The walls are varnished in 3 layers with high-quality drying of each of them. If the painting method is chosen, it is recommended to use paint that does not contain water in its composition. Thus, OSB boards are currently one of the most popular modern materials due to the fact that they have many positive properties, are easy to install and are affordable.

Technique for installing OSB on a wall.The most common way to finish OSB panels is to putty them, which can be used to remove all the cracks that are present at the joints. The putty can be acrylic, latex, or gypsum-based. It is best if the putty is colorless. Before puttying the walls, they must be primed. Further finishing of the walls can consist of painting or varnishing. Experts recommend that if varnishing the walls is chosen, use matte varnish. The walls are varnished in 3 layers with high-quality drying of each of them. If the painting method is chosen, it is recommended to use paint that does not contain water in its composition. Thus, OSB boards are currently one of the most popular modern materials due to the fact that they have many positive properties, are easy to install and are affordable.