The walls that have the largest area in the apartment areplay a very important role in the interior, and it is they that largely determine whether your home will look cozy or not. Therefore, during a major renovation of an apartment or the construction/renovation of a private house, the walls require the closest attention from the owners. Rough finishing is needed to level the wallsbefore painting or wallpapering. Any carelessness in their repair can come back to haunt you, both figuratively - in the form of cracks on the surface, and literally - it is unlikely that you can decorate your home with crooked, uneven walls. This can be prevented by interior rough finishing of the walls - the arrangement of a strong and even base on which the final decorative finish will be laid.

Rough finishing is needed to level the wallsbefore painting or wallpapering. Any carelessness in their repair can come back to haunt you, both figuratively - in the form of cracks on the surface, and literally - it is unlikely that you can decorate your home with crooked, uneven walls. This can be prevented by interior rough finishing of the walls - the arrangement of a strong and even base on which the final decorative finish will be laid.

Basic variants of rough finishing of walls

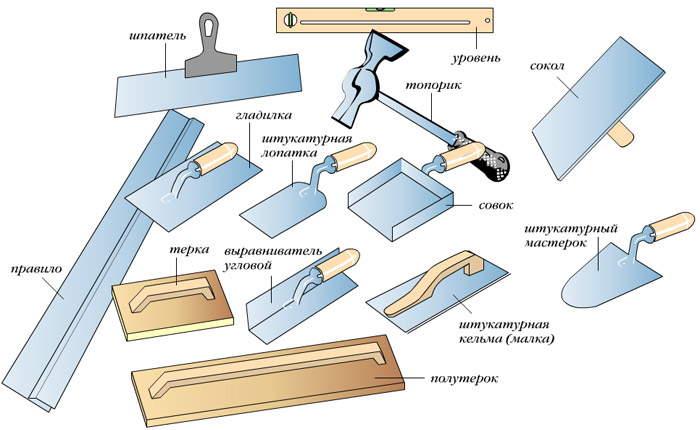

Rough finishing is a very important stageconstruction or major repairs of a house, although one of the most difficult, long and dirty. Today, to create a rough base, you can successfully use plaster - lime, gypsum or cement-sand, and plasterboard mounted on guide profiles or glue. Tools for rough finishing of wallsplaster. If desired, you can use a dozen more options, but if you plan to do it, it is better not to use them. Rough finishing is a troublesome business in itself, and there is no point in adding problems by resorting to its exotic options, during the execution of which you will almost certainly screw up. But no matter which one you choose, there is one general rule: after finishing, the wall should become as even as possible - both horizontally and vertically, and in the plane. Remember that the most expensive and high-quality finishing coating will not last long on a crooked wall, and it will not look very aesthetically pleasing on such a wall. And vice versa: even a not very prestigious coating applied to a leveled wall will please the eye. Return to contents</a>

Tools for rough finishing of wallsplaster. If desired, you can use a dozen more options, but if you plan to do it, it is better not to use them. Rough finishing is a troublesome business in itself, and there is no point in adding problems by resorting to its exotic options, during the execution of which you will almost certainly screw up. But no matter which one you choose, there is one general rule: after finishing, the wall should become as even as possible - both horizontally and vertically, and in the plane. Remember that the most expensive and high-quality finishing coating will not last long on a crooked wall, and it will not look very aesthetically pleasing on such a wall. And vice versa: even a not very prestigious coating applied to a leveled wall will please the eye. Return to contents</a>

Drywall or plaster?

Each of these materials has its own advantages andcons. The advantages of plaster include its durability - high-quality plaster applied to the walls will not require repairs for 30 years, and under favorable circumstances - even more. Plastering materials are almost half as cheap as drywall. Although the prices for plastering work are a quarter, and sometimes a third higher than for work with drywall. But if you plan to do the rough finishing yourself, then the latter circumstance can be ignored. Although it should be noted that it is more difficult for a non-professional to plaster the walls than to finish with drywall. Scheme of plastering a wall using beacons.High-quality plaster is a strong and impact-resistant base that is not afraid of heavy loads. Therefore, you can safely hang hanging furniture or equipment on such walls, unlike a plasterboard base, which in this case needs to be additionally reinforced. But finishing walls with plasterboard takes much less time and does not require the preparation of any solutions. In addition, if the walls themselves are uneven, then this does not matter much for plasterboard, but the layer of plaster to level these unevenness will have to be made thicker, thereby increasing the consumption and, accordingly, the cost of the material. For lining a bathroom or toilet, you need to use more expensive special moisture-resistant plasterboard. But even in this case, the service life of such finishing does not exceed 5-7 years. With plaster, such problems usually do not arise. From plasterboard, you can easily create arches, alcoves and other architectural forms. The plaster finish will strictly follow the plane of the wall. Plaster is applied directly to the wall, while a layer of insulation can be placed between the plasterboard and the wall. This factor can be decisive when choosing a material. But when finishing walls with plasterboard, a decrease in the volume of the room is inevitable, which does not happen when finishing with plaster. For small rooms, this factor can be decisive. Return to contents</a>

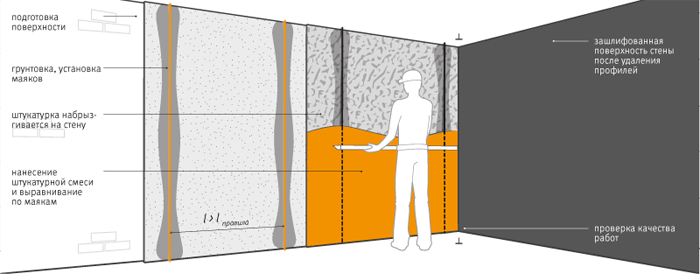

Scheme of plastering a wall using beacons.High-quality plaster is a strong and impact-resistant base that is not afraid of heavy loads. Therefore, you can safely hang hanging furniture or equipment on such walls, unlike a plasterboard base, which in this case needs to be additionally reinforced. But finishing walls with plasterboard takes much less time and does not require the preparation of any solutions. In addition, if the walls themselves are uneven, then this does not matter much for plasterboard, but the layer of plaster to level these unevenness will have to be made thicker, thereby increasing the consumption and, accordingly, the cost of the material. For lining a bathroom or toilet, you need to use more expensive special moisture-resistant plasterboard. But even in this case, the service life of such finishing does not exceed 5-7 years. With plaster, such problems usually do not arise. From plasterboard, you can easily create arches, alcoves and other architectural forms. The plaster finish will strictly follow the plane of the wall. Plaster is applied directly to the wall, while a layer of insulation can be placed between the plasterboard and the wall. This factor can be decisive when choosing a material. But when finishing walls with plasterboard, a decrease in the volume of the room is inevitable, which does not happen when finishing with plaster. For small rooms, this factor can be decisive. Return to contents</a>

Rough finishing with plasterboard

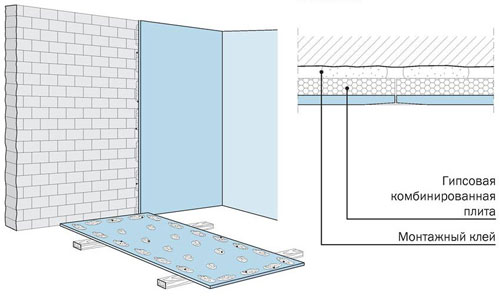

Scheme of rough finishing with plasterboard.Finishing the walls with plasterboard begins with installing a frame for attaching the sheets. The frame can be made of metal or wood, but in practice, 99% of the time, metal is used, since it is stronger and more durable, and is not afraid of fire or high humidity. To perform the work, you will need:

Scheme of rough finishing with plasterboard.Finishing the walls with plasterboard begins with installing a frame for attaching the sheets. The frame can be made of metal or wood, but in practice, 99% of the time, metal is used, since it is stronger and more durable, and is not afraid of fire or high humidity. To perform the work, you will need:

- drill (better electric);

- screwdriver (or screwdriver);

- level;

- roulette;

- plumb bob;

- metal shears (for wooden frame - hacksaw);

- putty knife;

- cutter for gypsum board.

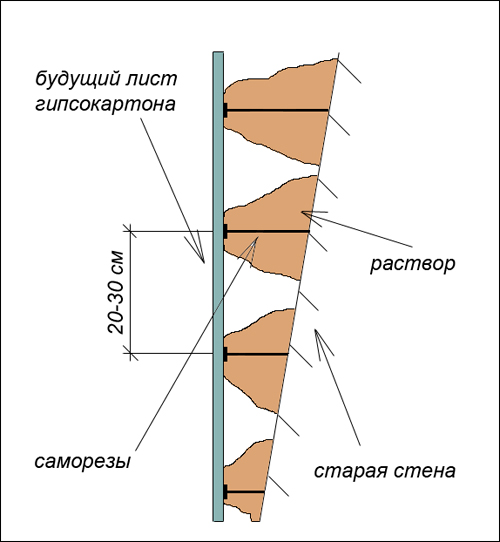

To install the frame, two types of profile are used:UD and SD. UD are used as guides along the entire perimeter of the frame, SD are inserted into them, mounting the fastening grid. Installation begins with marking the ceiling and fixing the guide profiles along this marking. After this, a plumb line is lowered from the attachment points and in those places where it touches the floor, the profiles are also fixed. Then, rack profiles are installed along the guide profiles. Each sheet must be attached to three profiles: 2 - on the sides and 1 in the middle. But when installing the frame, it is necessary to take into account that the edges of adjacent sheets of drywall are attached to one profile, lying on its halves from both sides. Therefore, when calculating, you need to be extremely accurate, taking the width of the sheet as the initial data. Tools for finishing walls with plasterboard.To make the frame stronger, its uprights are attached to the main wall using hangers. The hangers are attached to the wall plane with screws. The number of hangers in a row depends on the height of the room, usually 3-4 per row are required. Then, transverse stiffeners are attached to the uprights using screws. Having finished with the frame, you can start attaching the drywall sheets. The sheets are attached with countersunk screws, and the attachment point should be 1.5 cm from the end of the sheet, and at least 1 cm from its longitudinal edge. The screws are screwed in at a right angle and should enter the profile by at least 1 cm. There is another, frameless, method of rough finishing walls with drywall. To use it, you will need a special glue, with which the drywall sheets are attached to the wall. The choice of glue directly depends on the material of the wall itself: if it is a concrete slab, then you need to take it for a concrete surface, and if it is brick, then for brickwork. Despite the fact that this method of finishing does not require a frame, it also has its own difficulties. For example, it depends on the evenness of the walls, and if they are very curved, leveling the base will be problematic. Return to contents</a>

Tools for finishing walls with plasterboard.To make the frame stronger, its uprights are attached to the main wall using hangers. The hangers are attached to the wall plane with screws. The number of hangers in a row depends on the height of the room, usually 3-4 per row are required. Then, transverse stiffeners are attached to the uprights using screws. Having finished with the frame, you can start attaching the drywall sheets. The sheets are attached with countersunk screws, and the attachment point should be 1.5 cm from the end of the sheet, and at least 1 cm from its longitudinal edge. The screws are screwed in at a right angle and should enter the profile by at least 1 cm. There is another, frameless, method of rough finishing walls with drywall. To use it, you will need a special glue, with which the drywall sheets are attached to the wall. The choice of glue directly depends on the material of the wall itself: if it is a concrete slab, then you need to take it for a concrete surface, and if it is brick, then for brickwork. Despite the fact that this method of finishing does not require a frame, it also has its own difficulties. For example, it depends on the evenness of the walls, and if they are very curved, leveling the base will be problematic. Return to contents</a>

Rough finishing with plaster

To apply a layer of plaster to the wall,the surface must first be cleaned of dust, dirt, grease stains and old paint, otherwise the plaster will not adhere well to the surface and will quickly fall off. When preparing to plaster flat walls, sometimes to give their surface more roughness it is necessary to make notches with a chisel on concrete walls, and on brickwork - deepening and widening of cement joints. In any case, regardless of the wall material, it is necessary to prime the wall with a deep penetration primer so that the plaster adheres more firmly. If it is supposed to apply a thick layer (5 cm or more) of plaster, a reinforcing mesh is attached to the wall or a chain-link mesh with cells less than 5 cm is used. Scheme of leveling a wall without a frame. To apply rough plaster you will need:

Scheme of leveling a wall without a frame. To apply rough plaster you will need:

- poluterki;

- plaster blade;

- rule;

- level;

- drill;

- screwdriver or screwdriver.

Once you have finished preparing the walls, you can begindirectly to their plaster. There are two ways to apply plaster: spraying or smearing. Spraying cannot be avoided if the plaster cladding is carried out using a reinforcing mesh, in all other cases it is better to use smearing. It is both easier to perform and more economical in terms of material consumption. The plaster solution is prepared according to the instructions on the package of dry putty mix. Stepping back 20 cm from the corner, beacons are set up at each corner, and then, aligning with the set corner beacons, set up middle beacons at an interval of about 1 m. The plaster is spread (thrown on), focusing on the set beacons, filling the wall space between them to the desired height. The surface is leveled with a float or rule, passing their edge along the nearest beacons. After a few hours, when the plaster has dried, but is still wet, it is rubbed. Rubbing is done with circular movements of the hand with the float pressed tightly to the wall. Depending on the unevenness of the wall, adjust the pressure: on the depressions - weaker, on the hillocks - stronger. This is how the final rough alignment of the walls is completed. The final decision on the materials and method of rough finishing of the walls must be made in each specific case separately, taking into account many factors: is it a house or an apartment, what are the dimensions of the room, the height of the ceilings, the curvature of the walls, etc. The only general rule for rough finishing: whatever the finishing coating, it can be changed fairly quickly and painlessly. Rough finishing is the basis, and you need to try to make it so high-quality that you do not return to it again. Although someone who has gone through this procedure once, only extreme need can force him to return to it. Good luck!</ ul>