The warmth of the hearth has been praised since ancient times,and currently, electric underfloor heating is widely used with your own hands, which is not a problem for a master to install. Using electric heaters to increase the temperature in a room will entail large electricity bills, while underfloor heating is quite economical in this regard. Cable heating systems can be installed in any room: both residential and office or even industrial. Reliable and safe operation will be ensured if the floor is laid and installed correctly according to all the rules. Installation should begin with preparatory work and a detailed action plan. This stage will ensure the correct calculation of the required amount of all elements and materials. Before starting work, it is also necessary to calculate the required power of the electric cable used. Electric underfloor heating system diagram. Underfloor heating systems can be divided into 2 categories:

Electric underfloor heating system diagram. Underfloor heating systems can be divided into 2 categories:

- floor for self-styling;

- mesh with a cable laid.

The only difference between them is thatlaying the cable yourself gives the master more freedom in the placement of the cable in the room and in choosing the heating mode. The second option greatly simplifies the installation. A separate heating cable can be used as the main source of heating the room and as an additional one. The finished system, as a rule, is designed for low power and can only be used as additional heating. Connection diagram for cable underfloor heating.The cable used for underfloor heating installation can be self-regulating and resistive. Resistive cables have 1 or 2 cores that heat and have increased resistance. Based on this feature, they are divided into single-core and double-core. When installing underfloor heating, it is preferable to use a double-core cable, as it is more convenient to install and is also equipped with an additional electromagnetic radiation scattering function available in every energy system. This radiation was previously considered harmful to human health, and they tried to limit the use of electricity for heating. Several studies have been conducted to date, the results of which have revealed that the amount of radiation is very small and has no effect on humans. Self-regulating cables are called so because the current is regulated independently along their entire length, which affects the heating elements. Its regulation prevents any section of the cable from overheating and thus putting the entire system out of order, as happens with resistive cables. This feature of the self-regulating cable affects its price and popularity.

Connection diagram for cable underfloor heating.The cable used for underfloor heating installation can be self-regulating and resistive. Resistive cables have 1 or 2 cores that heat and have increased resistance. Based on this feature, they are divided into single-core and double-core. When installing underfloor heating, it is preferable to use a double-core cable, as it is more convenient to install and is also equipped with an additional electromagnetic radiation scattering function available in every energy system. This radiation was previously considered harmful to human health, and they tried to limit the use of electricity for heating. Several studies have been conducted to date, the results of which have revealed that the amount of radiation is very small and has no effect on humans. Self-regulating cables are called so because the current is regulated independently along their entire length, which affects the heating elements. Its regulation prevents any section of the cable from overheating and thus putting the entire system out of order, as happens with resistive cables. This feature of the self-regulating cable affects its price and popularity.

Materials and tools for installation

The process of installing electric underfloor heatingtiles. Most often, it is more profitable to buy a warm floor as a ready-made kit, which includes all the necessary elements. But when buying, you should also check the complete set so as not to buy one missing element at the last moment. To install a warm floor, you will need:

The process of installing electric underfloor heatingtiles. Most often, it is more profitable to buy a warm floor as a ready-made kit, which includes all the necessary elements. But when buying, you should also check the complete set so as not to buy one missing element at the last moment. To install a warm floor, you will need:

- mounting foil;

- foil scotch;

- mounting tape;

- self-tapping screws;

- temperature sensor;

- thermoregulator;

- corrugated channels;

- heating cable;

- metal grid;

- concrete;

- heat insulation.

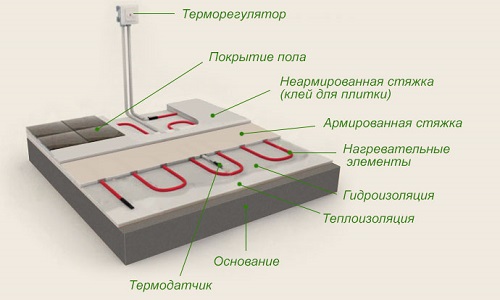

The structure of the underfloor heating installation for its long and trouble-free operation should look like this, its installation starts from the bottom: Construction of a resistive twin-core cable.

Construction of a resistive twin-core cable.

Among the arguments of opponents of underfloor heating are:hear that the structure of so many layers significantly reduces the living space, which is already small in modern apartments. In fact, the entire multi-layer system takes up no more than 8-10 cm, which is unlikely to greatly affect the height of the room's ceiling. Return to contents</a>

Preliminary stage of works for installation of a warm floor by own hands

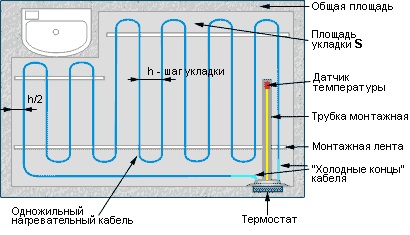

Laying single-core heating cable.The action plan usually begins with preparing a place on the wall for installing a special thermostat. This device is installed in a convenient place at a height of at least 30 cm from the floor and looks like an ordinary switch. The designated place on the wall is equipped with a special hole, into which the installation is made. From the installation hole towards the floor, the wall is grooved, and a power cable and a wire from the temperature sensor on the floor are laid along the finished groove. The wires are hidden in a special plastic box. Return to contents</a>

Laying single-core heating cable.The action plan usually begins with preparing a place on the wall for installing a special thermostat. This device is installed in a convenient place at a height of at least 30 cm from the floor and looks like an ordinary switch. The designated place on the wall is equipped with a special hole, into which the installation is made. From the installation hole towards the floor, the wall is grooved, and a power cable and a wire from the temperature sensor on the floor are laid along the finished groove. The wires are hidden in a special plastic box. Return to contents</a>

Warm floor - surface preparation

The floor surface is completely cleared of debris.and dust, before installation it should be level, free of drops and holes. If necessary, the floor surface should be leveled with a screed. The optimal layer of screed when laying is from 3 to 7 cm, if you pour the floor in a thinner layer, it will crack before it dries. Before pouring the screed, the floor is treated with special primer coatings that improve adhesion. Before pouring the floor, markings are made on the dried primer. Underfloor heating is not installed in places where stationary furniture will be located, and there should be a distance of at least 5 cm from the walls to the heating cable. Return to contents</a>

Laying of the insulation layer

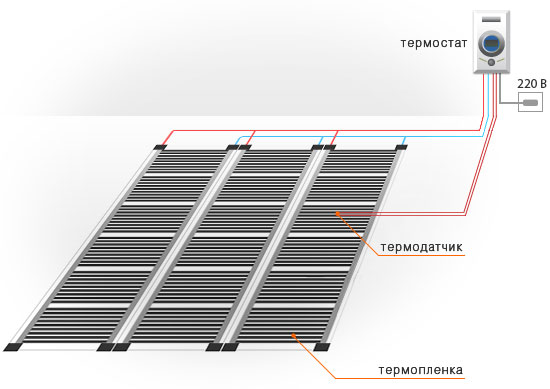

Wiring diagram for infrared heated floors.For high-quality and economical heating of the room using an electric floor, it is necessary to minimize heat loss. For this purpose, a layer of thermal insulation is laid on the concrete base of the floor, and only on it is the heating cable laid. This precaution helps to reduce heat loss by 30% or more. Thermal insulation on the floor can be laid in two ways:

Wiring diagram for infrared heated floors.For high-quality and economical heating of the room using an electric floor, it is necessary to minimize heat loss. For this purpose, a layer of thermal insulation is laid on the concrete base of the floor, and only on it is the heating cable laid. This precaution helps to reduce heat loss by 30% or more. Thermal insulation on the floor can be laid in two ways:

In case heated floors are plannedinstalled in a room where humidity is high, a waterproofing layer made of a material intended for this purpose should also be laid on top of it. This layer will prevent moisture from penetrating into the base of the floor and condensing there. This stage of work is especially relevant for apartments in multi-story buildings, where you need to think about the comfort of neighbors on the lower floors. Return to contents</a>

Laying screed and mounting tape

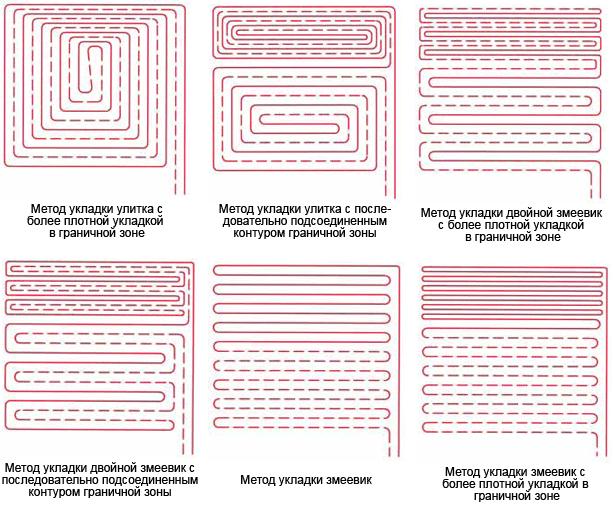

Schemes for laying underfloor heating pipelines.Before the heating cable is laid on the floor surface, the insulation layer must be filled with a screed, which consists of sand and cement. A layer of these materials prevents the cable from overheating and creates a solid base for its installation. In cases where pouring a screed is impossible, various substitutes for this stage of work are used. A fine-mesh metal mesh with a cell size of 1.5-2 cm can serve as a substitute. The heating cable is laid on the mesh, and the whole thing is filled with a finishing screed completely in one go. The metal mesh makes such a structure very durable, almost monolithic. If a preliminary screed was used, the floor after its application and drying is covered with mounting foil, which is also called foil insulation. It must be laid in one layer on the entire surface of the floor entirely with a good (at least 5 cm) reserve at the joints, the edges are glued with special foil tape, which prevents it from curling up during the cable installation. This foil screen helps distribute heat more evenly across the entire floor surface in the room. To keep the cable in the right position, a mounting tape is used. It is secured every 0.5 m using standard screws or nails. To secure the cable, the mounting tape has special clamps located at equal distances from each other. With the help of such clamps, the cable pitch is very easy to maintain without using a tape measure and constant calculations. Return to contents</a>

Schemes for laying underfloor heating pipelines.Before the heating cable is laid on the floor surface, the insulation layer must be filled with a screed, which consists of sand and cement. A layer of these materials prevents the cable from overheating and creates a solid base for its installation. In cases where pouring a screed is impossible, various substitutes for this stage of work are used. A fine-mesh metal mesh with a cell size of 1.5-2 cm can serve as a substitute. The heating cable is laid on the mesh, and the whole thing is filled with a finishing screed completely in one go. The metal mesh makes such a structure very durable, almost monolithic. If a preliminary screed was used, the floor after its application and drying is covered with mounting foil, which is also called foil insulation. It must be laid in one layer on the entire surface of the floor entirely with a good (at least 5 cm) reserve at the joints, the edges are glued with special foil tape, which prevents it from curling up during the cable installation. This foil screen helps distribute heat more evenly across the entire floor surface in the room. To keep the cable in the right position, a mounting tape is used. It is secured every 0.5 m using standard screws or nails. To secure the cable, the mounting tape has special clamps located at equal distances from each other. With the help of such clamps, the cable pitch is very easy to maintain without using a tape measure and constant calculations. Return to contents</a>

Heating cable laying

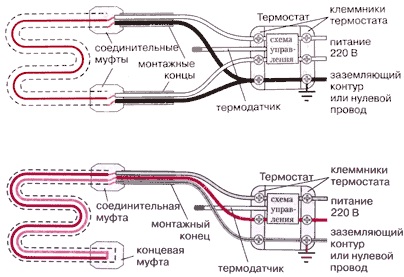

Connection diagram for 1- and 2-wireheating cable. Having referred to the pre-thought-out step-by-step installation plan, it is necessary to carefully check such stages of work as the order of laying out and the required minimum step between cable turns. When unwinding the cable, its resistance must be checked. This value must be measured and the result written down in the designated field in the warranty card attached to the floor kit. With an acceptable deviation of plus or minus 10%, the resistance value must match the one declared at the time of purchase, which is indicated on a special label. The found cold end of the wire is threaded through the corrugation and inserted into a pre-prepared chase channel. The connecting sleeve and the first centimeters of the cable to the floor are attached to the mounting tape, and from this point the laying out of the cable turns begins. It is necessary to additionally monitor the location of the sleeve on the floor, since it must subsequently be completely covered with concrete screed. During installation, it is necessary to monitor the cable turns and make them thoughtfully, since the cable should not touch the previous turns anywhere, much less cross them. At the same time, in places of turns and bends, the radius of curvature should not be less than 5 cm. A two-core cable has not only a connecting sleeve, but also an end sleeve, which is fixed with a mounting tape under the same conditions. The concrete screed at the final stage of work should cover it entirely. In cases where the cable is single-core, first the beginning of the cable is connected to the thermostat, and then its end. Return to contents</a>

Connection diagram for 1- and 2-wireheating cable. Having referred to the pre-thought-out step-by-step installation plan, it is necessary to carefully check such stages of work as the order of laying out and the required minimum step between cable turns. When unwinding the cable, its resistance must be checked. This value must be measured and the result written down in the designated field in the warranty card attached to the floor kit. With an acceptable deviation of plus or minus 10%, the resistance value must match the one declared at the time of purchase, which is indicated on a special label. The found cold end of the wire is threaded through the corrugation and inserted into a pre-prepared chase channel. The connecting sleeve and the first centimeters of the cable to the floor are attached to the mounting tape, and from this point the laying out of the cable turns begins. It is necessary to additionally monitor the location of the sleeve on the floor, since it must subsequently be completely covered with concrete screed. During installation, it is necessary to monitor the cable turns and make them thoughtfully, since the cable should not touch the previous turns anywhere, much less cross them. At the same time, in places of turns and bends, the radius of curvature should not be less than 5 cm. A two-core cable has not only a connecting sleeve, but also an end sleeve, which is fixed with a mounting tape under the same conditions. The concrete screed at the final stage of work should cover it entirely. In cases where the cable is single-core, first the beginning of the cable is connected to the thermostat, and then its end. Return to contents</a>

How to fasten the thermostat and the temperature sensor

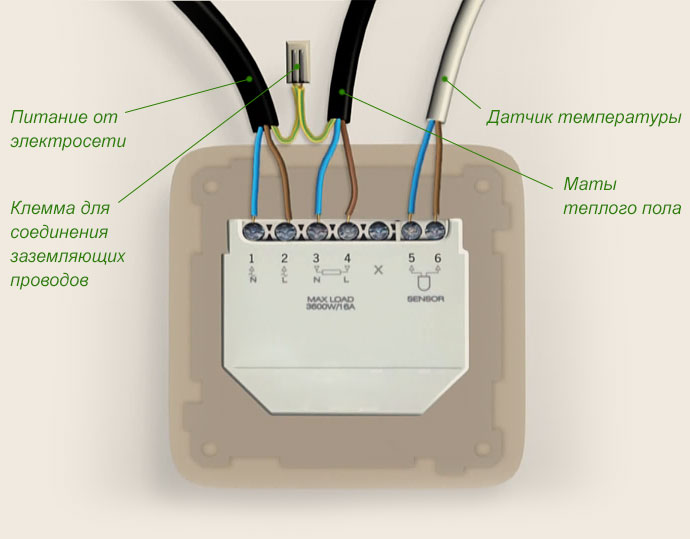

Example of connecting an electric heated floorto the thermostat. The sensors and the controller can be installed no earlier than the cable is completely laid out over the entire floor in the room. It is mounted inside the corrugated protective casing and installed in the same groove where the heating cable was previously installed from its power end. It is necessary to install a plug for the end of the tube with the thermostat, otherwise concrete will get inside during pouring. If the temperature sensor fails for some reason with such a well-thought-out installation method, it can be easily removed from its location and replaced with a working one. If you do not mount it in a separate tube, replacement will be impossible. When laying the tube containing the sensor on the floor, you need to place it between the laid turns of the cable, without crossing them or touching them. The tube is fixed strictly in the middle using mounting tape. The length of the tube for normal operation of the sensor should be at least 50-100 cm. The thermostat itself is installed and connected only after the final equipment of the junction box with 3 wires: the main network cable, the voltage of which is 220 V; the wire from the temperature sensor and the power wire from the heating cable. If the underfloor heating cable is installed in a room where the humidity is constantly high, it is prohibited to install the sensor in the same room - it must be brought through the wall to the next room. Installing the sensor in a room where the humidity is above the norm is prohibited, as it is a fire hazard. Return to the table of contents</a>

Example of connecting an electric heated floorto the thermostat. The sensors and the controller can be installed no earlier than the cable is completely laid out over the entire floor in the room. It is mounted inside the corrugated protective casing and installed in the same groove where the heating cable was previously installed from its power end. It is necessary to install a plug for the end of the tube with the thermostat, otherwise concrete will get inside during pouring. If the temperature sensor fails for some reason with such a well-thought-out installation method, it can be easily removed from its location and replaced with a working one. If you do not mount it in a separate tube, replacement will be impossible. When laying the tube containing the sensor on the floor, you need to place it between the laid turns of the cable, without crossing them or touching them. The tube is fixed strictly in the middle using mounting tape. The length of the tube for normal operation of the sensor should be at least 50-100 cm. The thermostat itself is installed and connected only after the final equipment of the junction box with 3 wires: the main network cable, the voltage of which is 220 V; the wire from the temperature sensor and the power wire from the heating cable. If the underfloor heating cable is installed in a room where the humidity is constantly high, it is prohibited to install the sensor in the same room - it must be brought through the wall to the next room. Installing the sensor in a room where the humidity is above the norm is prohibited, as it is a fire hazard. Return to the table of contents</a>

Screed and its device on the warm floor

Before you need to make sure it is completeperformance and absence of any malfunctions, since then they can be eliminated only by breaking the self-leveling coating. To check the operation of all elements, the warm floor is connected to the network for some time. The entire scheme of its installation in the open state with the location of the connecting and end couplings should be drawn or photographed in good quality, and the image should be included in the warranty card. The fill for the warm floor is prepared from special mixtures. The liquid mixed mixture is poured onto the surface evenly, with care and caution, in order to avoid damage to the cable insulation. It is necessary to carefully monitor the quality of the fill and prevent the formation of air pockets that will impair the uniform transfer of heat by the cable into the space. After drying, the thickness of the concrete layer, as a rule, is 3-5 cm. The period of complete hardening is approximately equal to 4 weeks, but each manufacturer places more precise instructions on this on the packaging separately. If, after the screed has completely dried, parts of the insulation remain sticking out along the edges of the walls, they must be carefully cut off. When the screed is completely dry, proceed to laying the final covering - tiles, laminate, etc.