Heated floors are very popular and can be installed under almost any finishing coating. You can make heated floors yourself by following the instructions. You can turn on the heated floor after the screed has completely dried, gradually increasing the temperature over three days after installation. There are the following types of heated floor systems:

You can turn on the heated floor after the screed has completely dried, gradually increasing the temperature over three days after installation. There are the following types of heated floor systems:

- water heating;

- heating mats;

- cable system;

- infrared thermo film.

Floors with water heating

Materials:

- waterproofing film;

- heat insulation (polystyrene);

- damper belt;

- reinforcing mesh;

- polypropylene or metal-plastic pipes for heating with a diameter of 16-20 mm;

- fastening for pipes;

- dry mortar for screed;

- a collector cabinet with accessories;

- circulation pump;

- water-heating boiler with shut-off valves;

- fitting.

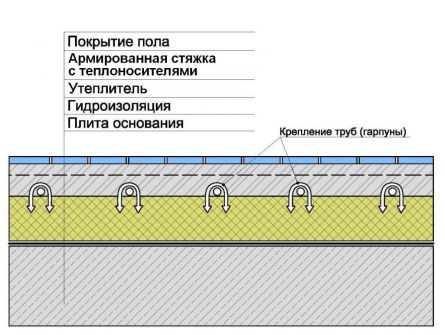

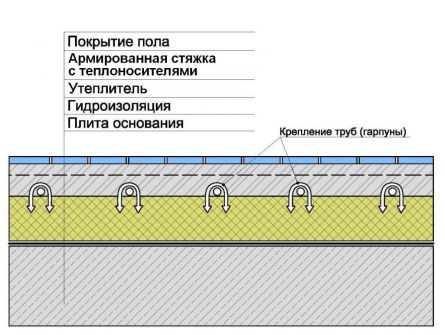

Scheme of the device of a water-heated floor with fastening of pipes with harpoons to a layer of thermal insulation. Tools:

Scheme of the device of a water-heated floor with fastening of pipes with harpoons to a layer of thermal insulation. Tools:

- tool for welding polypropylene pipes;

- Screwdriver;

- saw Rotorazer Saw;

- joiner's tools;

- chisel;

- building level;

- roulette.

Stages of laying a water-heated floor:

Preparation of the base for laying the underfloor heating. The surface must be free of debris and dust. If it has irregularities with a drop of 2-3 cm, it must be leveled.

Laying waterproofing to protect the heat insulator from moisture. On the perimeter of the room on the walls you need to paste a damper tape with a width equal to the height of the future floor level.

Surface reinforcement. A reinforcing mesh is placed on the heat-insulating layer, which will ensure an even distribution of the load.

Laying pipes.They should be fixed to the reinforcing mesh with special clips, fixing strips or ties, while avoiding excessive rigidity, since the pipes expand slightly during heating. The attachment points should be located at a distance of 1 m from each other. If the warm floor will serve as an auxiliary heating, then the pipes should be laid with a step of 30 cm, if the main one - 15-20 cm. One collector should have approximately 60 m of pipes. For rooms with large areas, several circuits are required.

Checking the work of the warm floor. When the installation is completed and all circuits are connected to the supply and return pipes, you need to check how the system works. Under high pressure, water is supplied to the pipes at a constant temperature. If the system works satisfactorily, start pouring the screed.

Pour the screed. It can have a thickness of 3-7 cm. It dries for 28 days.

The underfloor heating system can be turned on whenthe screed is completely dry, and gradually increase the temperature over 3 days. The pipes can be laid parallel, in a spiral, in a spiral with an offset center, meander, etc. Return to contents</a>

Heating mats

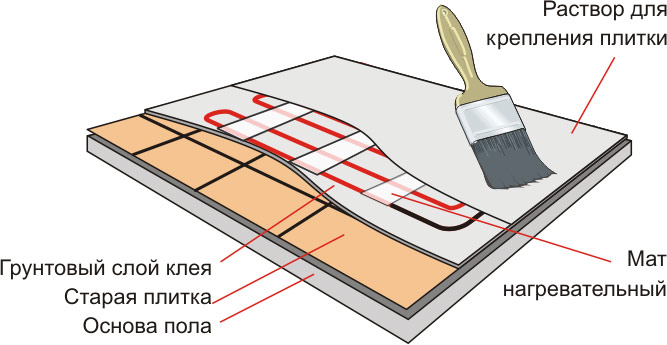

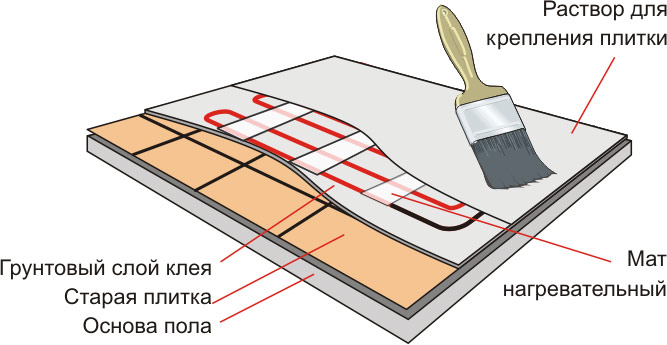

Heating mat installation diagram. Tools and materials for laying heating mats:

Heating mat installation diagram. Tools and materials for laying heating mats:

- heating mats;

- thermoregulator;

- a cross-head and a flat screwdriver;

- mounting tape, electrical tape;

- electronic tester.

Stages of installation of heating mats:

Checking the heating mats. The operating resistance must match the one specified on the packaging of the system. This can be checked by an ohmmeter or a multimeter.

Select the location of the sensor and cable output. The device is a recess in the floor for connecting wires and in the wall for the hood and carrying a channel for quick sensor replacement.

Cleaning and priming of the base for better adhesion of screed or tile glue.

Mounting the sensor of the underfloor heating system into the recess. The sensor must not intersect with the heating cable, or stay close to it.

When stacking heating mats, place the connecting wires near the sensor and the temperature controller.

Fix the mats. They can be attached to the floor in different ways: using mortar or adhesive tape.

Mount the thermostat to adjust the heating temperature of the warm floor. A sensor mounted on the wall at a height of 1 m from the floor will display the temperature.

After installing the heating mat systemcheck its operation. The cable must not be damaged or kinked, its resistance should be equal to the indices specified in the instruction, the screen should not contact the cores of the cable.

Fill the screed or lay the tile.

Tools for laying underfloor heating.When laying the mat strips to and from the wall, they need to be unrolled. Leave a distance of at least 6 cm between the cable turns. Do not lengthen or shorten the heating cable. Only the mesh can be cut in certain places. In difficult places for laying mats, the heating cable can be independently removed from the mesh and laid in any order with a distance of at least 6 cm. Return to the table of contents</a>

Tools for laying underfloor heating.When laying the mat strips to and from the wall, they need to be unrolled. Leave a distance of at least 6 cm between the cable turns. Do not lengthen or shorten the heating cable. Only the mesh can be cut in certain places. In difficult places for laying mats, the heating cable can be independently removed from the mesh and laid in any order with a distance of at least 6 cm. Return to the table of contents</a>

Electric heated floor

Materials:

- heat-insulating material;

- plastering mesh;

- plastic clips;

- single-core or double-core cable;

- thermoregulator with a temperature sensor;

- corrugated plastic tube;

- dowels;

- mounting tape;

- alabaster;

- primer;

- sand, cement and plasticizers for screed.

Tools:

- perforator;

- chisel;

- a hammer;

- scissors for metal;

- Ruler;

- notched trowel;

- solution tank.

Electric underfloor heating installation diagram. Laying the electric cable is almost identical to laying the heating mats. Stages of laying the electric underfloor heating:

Electric underfloor heating installation diagram. Laying the electric cable is almost identical to laying the heating mats. Stages of laying the electric underfloor heating:

Make a scheme of laying. The cable under the stationary furniture does not fit.

Lay the heat-insulating material with a heat-reflecting coating.

Lay down and fix the cable according to the scheme. Mount it can be a mounting tape with fasteners to the base or plastic clips to the metal mesh.

Make a marking on the floor, where stationary furniture and sanitary equipment will be located, and proceed to marking the area under the cable.

Mount the heating cable on the floor in accordance with the instructions.

Fit the thermostat.

Check the operation of the cable.

Fill the screed.

Return to Contents</a>

Infrared warm floor

Materials:

- infrared thermal film;

- thermoregulator with a temperature sensor;

- connecting clips for infrared film;

- contact clamps;

- heat-insulating material based on polypropylene film;

- electrical cable;

- tape and vinyl-mastic tape;

- building scotch.

Tools:

- tool for crimping connectors;

- flat screwdriver 3 mm;

- nippers

- a hammer;

- perforator;

- a tester for testing the connection of strips of thermal film;

- mounting knife.

Stages of installation of infrared heated floors: Infrared heated floor diagram.

Infrared heated floor diagram.

Prepare the base, clean it and if necessary level with a self-leveling mixture. The height difference should not exceed 3 mm.

Place the heat-reflecting substrate with the silver side up. Fix the substrate to the substrate with a construction tape.

Place the thermal film on the substrate with a copper strip down. Films should not overlap. Fix them with scotch tape.

Install the rivets under the connecting wires using a special tool for crimping the connectors. Connect the wiring and the terminal connections with tape.

Isolate all the places of exit of the copper strip along the cutting line of the infrared film. First, the tape is glued, then the vinyl mastic tape, and then again once again the usual tape.

Connect the thermostat with the temperature sensor to the system strictly according to the scheme in the manual.

Test the work of the finished system of infrared warm floor.

Lay the finish on the floor.

Before laying the infrared film, make aits placement scheme. Thermal film is not placed in places where stationary and heavy furniture is placed. The length of thermal film strips should not exceed 7 m. It can only be cut along special cutting lines with a step of 25 cm. Do not pierce the graphite black stripes of infrared film when you attach it to the base with staples or screws. Foil cannot be used as a heat-insulating layer.</ ul>

</ ul>

Comments

comments

You can turn on the heated floor after the screed has completely dried, gradually increasing the temperature over three days after installation. There are the following types of heated floor systems:

You can turn on the heated floor after the screed has completely dried, gradually increasing the temperature over three days after installation. There are the following types of heated floor systems: Scheme of the device of a water-heated floor with fastening of pipes with harpoons to a layer of thermal insulation. Tools:

Scheme of the device of a water-heated floor with fastening of pipes with harpoons to a layer of thermal insulation. Tools: Heating mat installation diagram. Tools and materials for laying heating mats:

Heating mat installation diagram. Tools and materials for laying heating mats: Tools for laying underfloor heating.When laying the mat strips to and from the wall, they need to be unrolled. Leave a distance of at least 6 cm between the cable turns. Do not lengthen or shorten the heating cable. Only the mesh can be cut in certain places. In difficult places for laying mats, the heating cable can be independently removed from the mesh and laid in any order with a distance of at least 6 cm. Return to the table of contents</a>

Tools for laying underfloor heating.When laying the mat strips to and from the wall, they need to be unrolled. Leave a distance of at least 6 cm between the cable turns. Do not lengthen or shorten the heating cable. Only the mesh can be cut in certain places. In difficult places for laying mats, the heating cable can be independently removed from the mesh and laid in any order with a distance of at least 6 cm. Return to the table of contents</a>  Electric underfloor heating installation diagram. Laying the electric cable is almost identical to laying the heating mats. Stages of laying the electric underfloor heating:

Electric underfloor heating installation diagram. Laying the electric cable is almost identical to laying the heating mats. Stages of laying the electric underfloor heating: Infrared heated floor diagram.

Infrared heated floor diagram.