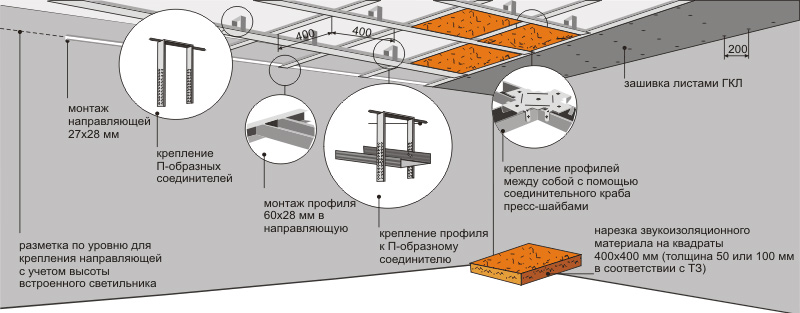

There is a large variety of products on the modern marketnumber of materials for installation of stretch ceilings, starting with satin canvases, ending with suede. Lumpy, single-color, colored, smooth stretch canvases will help to create original construction compositions of ceilings. Suspended and tension structures, possessing excellent qualities, but also disadvantages, are installed on the basis of various technological methods, the use of which will help people who have no idea how to do it themselves. Installation diagram of a plasterboard ceiling.

Installation diagram of a plasterboard ceiling.

Principles for installing gypsum board ceilings and special tools

To install a tension structure, you need:3 to 5 hours of work, which will be done by two experienced craftsmen. To install the ceiling structure yourself, for example, from plasterboard, you will need to work for two or three work shifts. Stretch ceilings differ from plasterboard in that they allow you to create the most unique shapes, distinguished by simplicity and ease of maintenance. Tools for installing plasterboard ceilings.The use of ceiling structures in the presence of high humidity in the room should not cause concern for the owner of the suspended ceiling. Here, the support of a master will be needed, who will drain the water or change the canvas for an additional fee. The use of plasterboard in conditions of high humidity will spoil the appearance of the ceiling, but the material itself is much cheaper than the stretch canvas. You can cope with the process of replacing the materials used for suspended ceilings yourself. At the same time, making the ceiling yourself will be too expensive, because you need to buy all the tools, and then they may not be needed. It is not difficult to install the ceiling yourself. The following tools will be needed when installing a suspended ceiling made of plasterboard:

Tools for installing plasterboard ceilings.The use of ceiling structures in the presence of high humidity in the room should not cause concern for the owner of the suspended ceiling. Here, the support of a master will be needed, who will drain the water or change the canvas for an additional fee. The use of plasterboard in conditions of high humidity will spoil the appearance of the ceiling, but the material itself is much cheaper than the stretch canvas. You can cope with the process of replacing the materials used for suspended ceilings yourself. At the same time, making the ceiling yourself will be too expensive, because you need to buy all the tools, and then they may not be needed. It is not difficult to install the ceiling yourself. The following tools will be needed when installing a suspended ceiling made of plasterboard:

- hacksaw for metal;

- filament yarn;

- Bulgarian;

- roulette;

- perforator or drill with impact mode (with drill);

- ladder;

- screwdriver with bit set;

- a hammer;

- scissors for metal;

- rule;

- tracer (chocline);

- water, laser level.

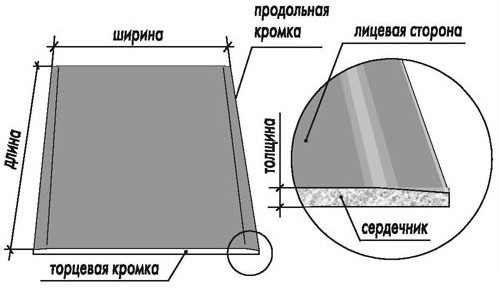

You can create a ceiling using the following materials: Diagram of the structure of a plasterboard sheet.

Diagram of the structure of a plasterboard sheet.

- drywall;

- steel profile;

- hangers;

- self-tapping screws;

- dowels;

- tapes for strengthening the connection points;

- putty;

- self-tapping screws.

The whole process of ceiling installation is quitelabor-intensive, but it is also possible to carry out the work by installing and finishing a plasterboard ceiling using a stretch fabric. The developed ceiling design due to the suspended and stretch structure will give the interior a special beauty, an interesting and mysterious look. All work that is done independently includes:

- the development of the design of the ceiling structure from plasterboard;

- fabrication of a skeleton for a ceiling structure;

- fixing drywall to the ceiling;

- shpaklevku ceiling construction;

- painting or pasting wallpaper on core material from gypsum board.

Return to Contents</a>

How to design the ceiling design yourself

Design the entire ceiling layout includingboth a plasterboard sheet and a stretch fabric, you can do it yourself, if you have special experience. The appropriate use of all the necessary materials will help to save the ceiling for a long time, so as not to repair this structure too often. First of all, when developing the design of the ceiling structure, it is necessary to remember that PVC stretch ceilings are mounted when using a plasterboard structure most successfully and economically profitable, if you use only a stretch fabric. It is possible to make it only from plasterboard, polycarbonate or plastic, but for the sake of an interesting play of light, colors and shadows, opening up unlimited possibilities for design, it is becoming increasingly acceptable to use stretch fabrics when decorating a room. As a result, taking into account the positive selection of finishing materials, the entire ceiling structure turns out to be spectacular and comfortable. It is better to compare with plasterboard elements a lacquered stretch ceiling or a glossy one. Decorated with lighting, softly reflecting the entire room, which is provided for by the interior design, the ceiling will visually increase it. Return to contents</a>

How to make a skeleton for a suspended ceiling and set a level of drywall

Layout diagram for a two-level ceiling.Before starting work, you should accurately take all the necessary measurements. Since the ceiling may be uneven, it is best to measure its parameters over the entire surface of the wall. The wall should be smooth, without defects on the surface. For measurements, you can use improvised means, which will allow you to not determine the size of each defective line on the ceiling. The ceiling material should be attached to a pre-made frame. It is created using a metal profile or a wooden lathing. First, you should draw a lighting diagram on a sheet of paper. The use of spotlights is a fashionable trend, so it is best to prepare special electrical wiring for them. It is best to bring the wire to the ceiling, having made a groove in advance. After all the work is done, they begin to mount the frame. The frame is not made without a preliminary diagram, since it allows you to provide for each protrusion on the ceiling, which will make it more beautiful. Installation of various shapes of steps for protrusions can sometimes be done on the floor, and then hung on the ceiling using a profile or lathing.

Layout diagram for a two-level ceiling.Before starting work, you should accurately take all the necessary measurements. Since the ceiling may be uneven, it is best to measure its parameters over the entire surface of the wall. The wall should be smooth, without defects on the surface. For measurements, you can use improvised means, which will allow you to not determine the size of each defective line on the ceiling. The ceiling material should be attached to a pre-made frame. It is created using a metal profile or a wooden lathing. First, you should draw a lighting diagram on a sheet of paper. The use of spotlights is a fashionable trend, so it is best to prepare special electrical wiring for them. It is best to bring the wire to the ceiling, having made a groove in advance. After all the work is done, they begin to mount the frame. The frame is not made without a preliminary diagram, since it allows you to provide for each protrusion on the ceiling, which will make it more beautiful. Installation of various shapes of steps for protrusions can sometimes be done on the floor, and then hung on the ceiling using a profile or lathing. Scheme of a two-level plaster ceiling.After the frame is installed, they begin to lay the wiring, and only then do they finish the frame with material. You can use not only plasterboard, but also polycarbonate, which includes acrylic plastic. To cover the joints and screws on the plasterboard ceiling, you can use putty, and for plastic, other finishing materials are provided, the cost of which is not too high. After attaching the sheet of material to the frame, at the same time, through the hole in the sheet provided for the lamp, an electric wire is brought out. These holes are made in advance, while the sheet is not yet attached to the frame. After fixing all the main sheets, they begin installing the steps, for which it is necessary to give the frame from the profile or lathing the appropriate shape. Return to the table of contents</a>

Scheme of a two-level plaster ceiling.After the frame is installed, they begin to lay the wiring, and only then do they finish the frame with material. You can use not only plasterboard, but also polycarbonate, which includes acrylic plastic. To cover the joints and screws on the plasterboard ceiling, you can use putty, and for plastic, other finishing materials are provided, the cost of which is not too high. After attaching the sheet of material to the frame, at the same time, through the hole in the sheet provided for the lamp, an electric wire is brought out. These holes are made in advance, while the sheet is not yet attached to the frame. After fixing all the main sheets, they begin installing the steps, for which it is necessary to give the frame from the profile or lathing the appropriate shape. Return to the table of contents</a>

We make a two-level suspended ceiling from plasterboard

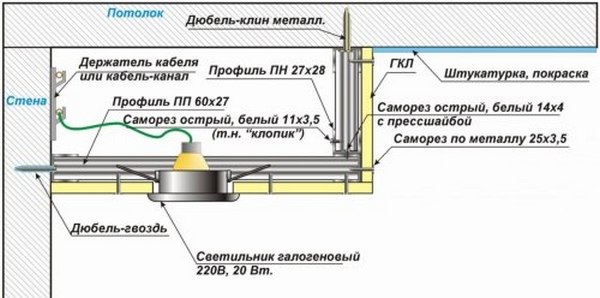

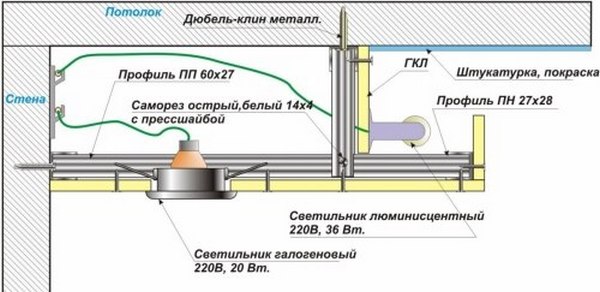

Image 1.Scheme of fastening a two-level ceiling without backlighting on the first level. Before, it is necessary to find out what will be the highest level that can be left: the existing ceiling, or a plasterboard ceiling, or a stretch fabric. If the ceiling surface is smooth, then you will not need to spend additional funds or waste time on leveling it. If you need to make several levels, then the surface of the existing ceiling in the room should be painted and plastered, and then start installing a new level of plasterboard. To make a two-level ceiling in the first way, that is, without backlighting, you need to make a continuous joint, installing each of the lamps on the second ceiling level of plasterboard. This is shown in the diagram (Image 1). The installation of a two-level ceiling in the second way is carried out according to a special scheme, for example, as in the figure (Image 2), and hidden lighting is provided in the ceiling structure. Thanks to this design, the effect of diffused soft light is created. Plasterboard is used to create two levels, one of which will be equipped with halogen lighting fixtures.

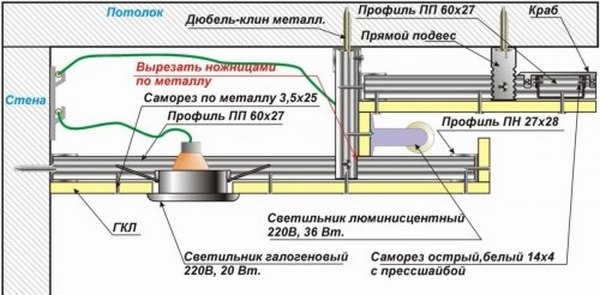

Image 1.Scheme of fastening a two-level ceiling without backlighting on the first level. Before, it is necessary to find out what will be the highest level that can be left: the existing ceiling, or a plasterboard ceiling, or a stretch fabric. If the ceiling surface is smooth, then you will not need to spend additional funds or waste time on leveling it. If you need to make several levels, then the surface of the existing ceiling in the room should be painted and plastered, and then start installing a new level of plasterboard. To make a two-level ceiling in the first way, that is, without backlighting, you need to make a continuous joint, installing each of the lamps on the second ceiling level of plasterboard. This is shown in the diagram (Image 1). The installation of a two-level ceiling in the second way is carried out according to a special scheme, for example, as in the figure (Image 2), and hidden lighting is provided in the ceiling structure. Thanks to this design, the effect of diffused soft light is created. Plasterboard is used to create two levels, one of which will be equipped with halogen lighting fixtures. Image 2.Scheme of fastening a two-level ceiling using hidden lighting. The second level can be arranged in the third way by mounting, covered with plasterboard, and not plastered, as in the first option. This is reflected in the diagram (Image 3). First, a plan is drawn up, which shows the layout of the sheets. The drawing is made taking into account all the required sizes of the gypsum board, which speeds up the installation process. Considering the standard sizes of the sheet, it will be more convenient to make the ceiling structure. Before installing the gypsum board on it, the ceiling is cleaned, and large cracks on it are putty. A corrugated pipe or metal sleeve is used to lay electrical cables. Using a laser level, as well as a painter's thread, you should mark the space where the upper level of the ceiling is attached, taking into account the entire perimeter of the room. At the same time, the thickness of the gypsum board sheet should be taken into account. Return to the table of contents</a>

Image 2.Scheme of fastening a two-level ceiling using hidden lighting. The second level can be arranged in the third way by mounting, covered with plasterboard, and not plastered, as in the first option. This is reflected in the diagram (Image 3). First, a plan is drawn up, which shows the layout of the sheets. The drawing is made taking into account all the required sizes of the gypsum board, which speeds up the installation process. Considering the standard sizes of the sheet, it will be more convenient to make the ceiling structure. Before installing the gypsum board on it, the ceiling is cleaned, and large cracks on it are putty. A corrugated pipe or metal sleeve is used to lay electrical cables. Using a laser level, as well as a painter's thread, you should mark the space where the upper level of the ceiling is attached, taking into account the entire perimeter of the room. At the same time, the thickness of the gypsum board sheet should be taken into account. Return to the table of contents</a>

Mounting of ceiling guides and plasterboard on the ceiling

Image 3.Mounting hidden lighting on a plasterboard ceiling. The process of installing profile guides is mandatory, for this you need to have a laser or pencil at hand. In order to strengthen the UD profile, you can use the "dowel-nail" system, associated with quick fastening. To do this, first apply the profile to the wall surface, then make a hole with a hammer drill, into which you need to hammer the dowel-nail. It is more convenient to fasten the guides together. The installation of the starting guides is carried out on the basis of checking their evenness with a building level, after which they are aligned. You can strengthen them by starting with cutting the guides. Next, a CD profile is mounted along the entire perimeter of the ceiling, it must be inserted into the guides, which were previously installed opposite each other. You can eliminate the sagging of the CD profile by mounting direct hangers using perforated metal tape. You can strengthen the profile with dowel wedges.

Image 3.Mounting hidden lighting on a plasterboard ceiling. The process of installing profile guides is mandatory, for this you need to have a laser or pencil at hand. In order to strengthen the UD profile, you can use the "dowel-nail" system, associated with quick fastening. To do this, first apply the profile to the wall surface, then make a hole with a hammer drill, into which you need to hammer the dowel-nail. It is more convenient to fasten the guides together. The installation of the starting guides is carried out on the basis of checking their evenness with a building level, after which they are aligned. You can strengthen them by starting with cutting the guides. Next, a CD profile is mounted along the entire perimeter of the ceiling, it must be inserted into the guides, which were previously installed opposite each other. You can eliminate the sagging of the CD profile by mounting direct hangers using perforated metal tape. You can strengthen the profile with dowel wedges. First level installation diagram.The distance between the ceiling guides should be 40 cm, and between the hangers - 60 centimeters. The guides can be adjusted using a level, and they must be attached to the hangers with self-tapping screws. The ends of the guides should be bent or cut. If necessary, sound insulation is laid. The second tier of the ceiling structure is fastened by additional reinforcement with transverse guides using the "crab" connection method. The plasterboard on the upper tier of the ceiling can be strengthened with self-tapping screws and a screwdriver. For this, you need assistants, since the weight of one plasterboard is 20 kg. Stepladders are used in the process of fastening the plasterboard. It is not necessary to strengthen the plasterboard in places where the second tier of the suspended ceiling structure passes; it can be left free, since it should go under the lower tier by 10-15 cm. When planning the installation of lamps on the upper tier, a number of holes are made, pulling the cable to them, otherwise it will be inconvenient to do it later. In order to fix the plasterboard, a border is marked on it where the lower tier should be. A pencil is used for this. The fixing is similar to the installation of the first tier. It should be located along the perimeter of the room or on one side of it.

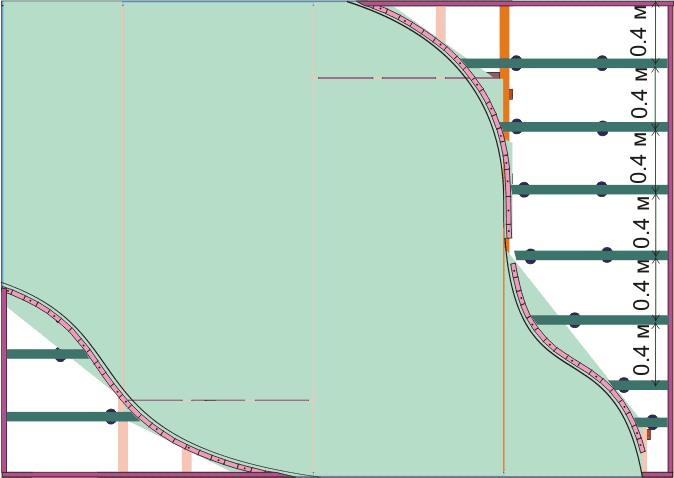

First level installation diagram.The distance between the ceiling guides should be 40 cm, and between the hangers - 60 centimeters. The guides can be adjusted using a level, and they must be attached to the hangers with self-tapping screws. The ends of the guides should be bent or cut. If necessary, sound insulation is laid. The second tier of the ceiling structure is fastened by additional reinforcement with transverse guides using the "crab" connection method. The plasterboard on the upper tier of the ceiling can be strengthened with self-tapping screws and a screwdriver. For this, you need assistants, since the weight of one plasterboard is 20 kg. Stepladders are used in the process of fastening the plasterboard. It is not necessary to strengthen the plasterboard in places where the second tier of the suspended ceiling structure passes; it can be left free, since it should go under the lower tier by 10-15 cm. When planning the installation of lamps on the upper tier, a number of holes are made, pulling the cable to them, otherwise it will be inconvenient to do it later. In order to fix the plasterboard, a border is marked on it where the lower tier should be. A pencil is used for this. The fixing is similar to the installation of the first tier. It should be located along the perimeter of the room or on one side of it. Installation diagram of the second level of the suspendedplasterboard ceiling. The guides are attached at the required distance, taking into account the level of the height difference to the first tier of the ceiling structure. To make a wave, the profile is cut with scissors. A curved shape can be given to the profile by cutting it with nippers. The guides of the lower tier are attached with spring hangers. For this, long rods are used, fixed at the required height due to the pressure spring. The hangers should be strengthened in such a way as to place the guides at a right angle to the very edge of the second tier. In this case, it is necessary to observe a fastening step of no more than 90 cm, and the size of the distance of the last hanger from the edge of the lower tier of the ceiling structure should be 10 cm. The guides can be fixed with spring hangers, which are cut in such a way that they can more accurately repeat the shape of the lower tier. The metal profile attached to the guides should form an angle in relation to the vertical plane. To give the level the shape of a wave, it is necessary to cut the metal profile. Between the second and first tiers of the ceiling structure, it is imperative to install vertical guides. The creation of the second level must necessarily be accompanied by the fastening of the frame from a metal profile. The plasterboard should be cut with a jigsaw or a knife, and then the sheet should be fixed to the guides. The side wall of the second level is connected to each of the vertical guides. After this, the cables are immediately brought out to connect the lamps.

Installation diagram of the second level of the suspendedplasterboard ceiling. The guides are attached at the required distance, taking into account the level of the height difference to the first tier of the ceiling structure. To make a wave, the profile is cut with scissors. A curved shape can be given to the profile by cutting it with nippers. The guides of the lower tier are attached with spring hangers. For this, long rods are used, fixed at the required height due to the pressure spring. The hangers should be strengthened in such a way as to place the guides at a right angle to the very edge of the second tier. In this case, it is necessary to observe a fastening step of no more than 90 cm, and the size of the distance of the last hanger from the edge of the lower tier of the ceiling structure should be 10 cm. The guides can be fixed with spring hangers, which are cut in such a way that they can more accurately repeat the shape of the lower tier. The metal profile attached to the guides should form an angle in relation to the vertical plane. To give the level the shape of a wave, it is necessary to cut the metal profile. Between the second and first tiers of the ceiling structure, it is imperative to install vertical guides. The creation of the second level must necessarily be accompanied by the fastening of the frame from a metal profile. The plasterboard should be cut with a jigsaw or a knife, and then the sheet should be fixed to the guides. The side wall of the second level is connected to each of the vertical guides. After this, the cables are immediately brought out to connect the lamps.