How to make a column from plasterboard?Since ancient times, columns have served as supports in buildings. They supported ceilings and balconies. Now these structures are used for decorative purposes. For example, heating risers, water and sewer pipes can be disguised as columns. They can be used to divide a room into zones. Spotlights can be built into a column. Nowadays, columns are often used inas a decorative element, so plasterboard is a suitable material for them. Previously, columns were made of hewn stones. Currently, supporting columns are made of concrete, which does not look very attractive. Therefore, they are most often covered with plasterboard. Modern columns are increasingly made as a decorative element, so plasterboard is a suitable material for them. It allows you to make structures of any shape. Even a non-professional can build a column from plasterboard, the main thing is to know the technology and some features.

Nowadays, columns are often used inas a decorative element, so plasterboard is a suitable material for them. Previously, columns were made of hewn stones. Currently, supporting columns are made of concrete, which does not look very attractive. Therefore, they are most often covered with plasterboard. Modern columns are increasingly made as a decorative element, so plasterboard is a suitable material for them. It allows you to make structures of any shape. Even a non-professional can build a column from plasterboard, the main thing is to know the technology and some features.

What do you need to do the work?

Before making a plasterboard column, you should prepare everything you need for the work. The following tools may be needed for this: Tools for performing work on the construction of the column.

Tools for performing work on the construction of the column.

- level or construction plumb line;

- Screwdriver;

- drill;

- scissors for metal;

- perforator;

- putty knife;

- compass;

- gon;

- roller;

- pencil or marker.

To make the column you will need sheetsplasterboard (GKL), metal profile, fasteners. Work begins with the installation of the frame. Its design depends on the chosen column shape. Return to contents</a>

Features of the device of a square or rectangular column

Before you start working, you should determinethe location of the column, and also think over its shape. It is not so difficult to make a rectangular or square structure. First, you should use a pencil or marker to draw the outline of the future column on the ceiling. The resulting lines should be transferred to the floor. This can be done using a plumb line or level. You can make such a plumb line yourself. To do this, you need to tie a bolt, nut or other weight to a rope or cord of the required length. The appearance of the column depends on the accuracy of the markings and its transfer to the floor. Scheme of the metal frame of the column fromplasterboard. After this, you can start building the frame. To do this, cut the metal profile with metal scissors, install it according to the markings and screw it to the floor and ceiling. Fasten the profile to the concrete base using dowel nails, to the wooden floor - with self-tapping screws. The corners of the frame must be reinforced by fastening the metal profiles with special fasteners at an angle of 90 °. Next, install vertical posts equal to the height of the room. If the column is placed near the wall, then two such posts are needed. If the column is installed in the middle of the room, then there should be four vertical posts. The resulting frame should be reinforced by installing additional profiles on the guides every 50-60 cm. The vertical posts are attached to the ceiling and floor profiles, they must be connected to each other with horizontal sections. The distance between the crossbars should be 50 cm. The frame is ready. The next stage of the column construction is covering it with plasterboard sheets. To do this, transfer the column dimensions onto them. Using a construction knife, cut out the necessary parts. The sheets are screwed to the metal profiles with self-tapping screws. The frame covered with plasterboard should be filled, decorated and the corners leveled with a special perforated corner. The column is almost ready, only the finishing remains. It can be decorated with decorative plaster, wallpapered, painted, finished with artificial or natural stone, or another type of cladding can be chosen. The final stage of finishing will be the installation of ceiling and floor skirting boards. Return to contents</a>

Scheme of the metal frame of the column fromplasterboard. After this, you can start building the frame. To do this, cut the metal profile with metal scissors, install it according to the markings and screw it to the floor and ceiling. Fasten the profile to the concrete base using dowel nails, to the wooden floor - with self-tapping screws. The corners of the frame must be reinforced by fastening the metal profiles with special fasteners at an angle of 90 °. Next, install vertical posts equal to the height of the room. If the column is placed near the wall, then two such posts are needed. If the column is installed in the middle of the room, then there should be four vertical posts. The resulting frame should be reinforced by installing additional profiles on the guides every 50-60 cm. The vertical posts are attached to the ceiling and floor profiles, they must be connected to each other with horizontal sections. The distance between the crossbars should be 50 cm. The frame is ready. The next stage of the column construction is covering it with plasterboard sheets. To do this, transfer the column dimensions onto them. Using a construction knife, cut out the necessary parts. The sheets are screwed to the metal profiles with self-tapping screws. The frame covered with plasterboard should be filled, decorated and the corners leveled with a special perforated corner. The column is almost ready, only the finishing remains. It can be decorated with decorative plaster, wallpapered, painted, finished with artificial or natural stone, or another type of cladding can be chosen. The final stage of finishing will be the installation of ceiling and floor skirting boards. Return to contents</a>

Features of the device of a round or semicircular column

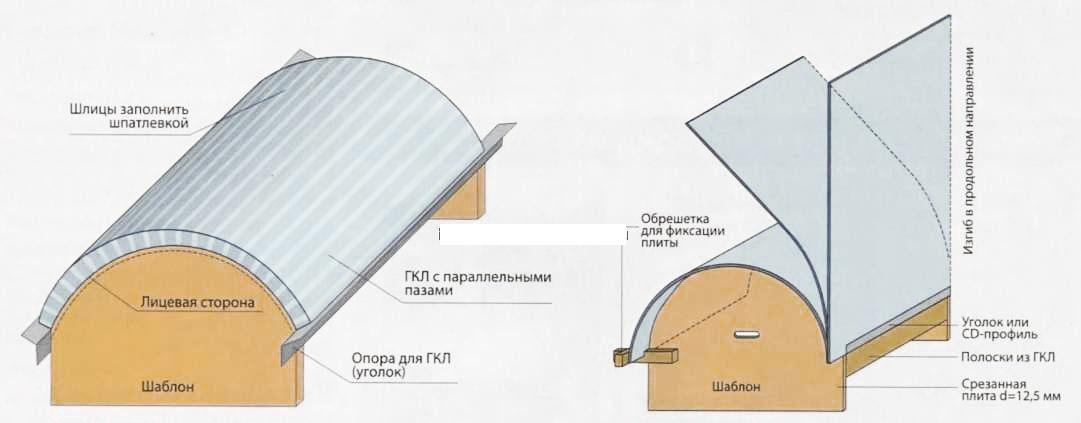

Scheme of finishing a column with a sheet of plasterboard.The use of plasterboard for mounting a column allows you to create a round or semicircular structure. To do this, mark the outline of the future column on the ceiling using a compass or a lath (in the case of a large diameter). You can make the lath yourself. To do this, attach a screw or nail to one edge, and a pencil to the other. Then, using a plumb line, transfer the outline of the column to the floor. The frame is made of a metal profile. To give the guides a round or semicircular shape, it is necessary to make cuts on the profile every 7-10 cm. The vertical profile must be installed frequently, in accordance with the radius along which the guides are bent. After completing the frame, you can begin to sheathe the column with plasterboard. There are some peculiarities here. There are two ways to perform this action. For large-diameter columns, the sheathing process occurs as follows:

Scheme of finishing a column with a sheet of plasterboard.The use of plasterboard for mounting a column allows you to create a round or semicircular structure. To do this, mark the outline of the future column on the ceiling using a compass or a lath (in the case of a large diameter). You can make the lath yourself. To do this, attach a screw or nail to one edge, and a pencil to the other. Then, using a plumb line, transfer the outline of the column to the floor. The frame is made of a metal profile. To give the guides a round or semicircular shape, it is necessary to make cuts on the profile every 7-10 cm. The vertical profile must be installed frequently, in accordance with the radius along which the guides are bent. After completing the frame, you can begin to sheathe the column with plasterboard. There are some peculiarities here. There are two ways to perform this action. For large-diameter columns, the sheathing process occurs as follows:

The second method of covering the column isthat in order to bend the plasterboard, it must be wet. First, a needle roller is passed over the top layer of plasterboard. Its surface is damaged, after which you can go over it with a wet sponge. The plaster will absorb the water. Such a sheet can be easily bent. It should be remembered that the plasterboard can be destroyed if the moisture is excessive. The plasterboard bent in this way is screwed to the frame with self-tapping screws. After this, the column is puttied and faced. If the column hides sewer or water pipes, it is necessary to take care of sound insulation. For this, you can use, for example, mineral wool slabs. Sound insulation should be installed before covering the column with plasterboard. If you plan to install lighting in the column, do not forget about the electrical wiring for the lamps. Return to the table of contents</a>

Summarizing

The column can become quite originalinterior element. This can be either a false column or a structure in which you can hide unsightly water or sewer pipes. Additional light sources can be cut into the column. It is not that difficult to make a structure from plasterboard, especially if this structure is rectangular or square. A round or semicircular structure can also be made by following the technology described above.