The door frame is the frame of the entire door. The strength and quality of the entire structure depends on how to make a frame for an interior door. Door frame device.Currently, doors are offered complete with a door frame. Such sets can have different designs and be made from different materials. Despite this, the issue of assembling a frame for an interior door with your own hands is relevant. A door frame made independently will fit exactly into the opening and will take into account the wishes of the owner.

Door frame device.Currently, doors are offered complete with a door frame. Such sets can have different designs and be made from different materials. Despite this, the issue of assembling a frame for an interior door with your own hands is relevant. A door frame made independently will fit exactly into the opening and will take into account the wishes of the owner.

Features of the box for the interior door

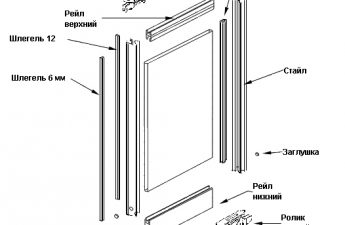

The frame of any door isits fixed part, which is fixed in the doorway and on which the hinges for installing the movable part - the door leaf - are placed. It is directly adjacent to the wall of the doorway. Sections of door frames of different types.The frame of an interior door has a frame type. It can be made of wood, pressed wood materials, plastic, light metal profiles or composite material. Most door frames are rectangular, and of standard sizes. However, the arched type is used. Functionally, the frame in the interior opening can play the role of a frame for the door or simply a limiter of the opening, performing mainly a decorative function (without hanging the door leaf). The design of the door frame is simple and includes a frame, casing and threshold, and can also contain a seal. The frame has a U-shape and is made up of two side posts and an upper horizontal crossbar (in the arched type - arc-shaped), rigidly fastened at the corners. The beams from which the frame is made have a characteristic box profile with a longitudinal recess for the entry of the door leaf. The casing is made from a decorative strip with 45º beveled ends and serves to hide the gap between the wall and the frame. The threshold completes the structure at the bottom in the form of a horizontal strip. A seal can be installed to provide sound insulation. Return to contents</a>

Sections of door frames of different types.The frame of an interior door has a frame type. It can be made of wood, pressed wood materials, plastic, light metal profiles or composite material. Most door frames are rectangular, and of standard sizes. However, the arched type is used. Functionally, the frame in the interior opening can play the role of a frame for the door or simply a limiter of the opening, performing mainly a decorative function (without hanging the door leaf). The design of the door frame is simple and includes a frame, casing and threshold, and can also contain a seal. The frame has a U-shape and is made up of two side posts and an upper horizontal crossbar (in the arched type - arc-shaped), rigidly fastened at the corners. The beams from which the frame is made have a characteristic box profile with a longitudinal recess for the entry of the door leaf. The casing is made from a decorative strip with 45º beveled ends and serves to hide the gap between the wall and the frame. The threshold completes the structure at the bottom in the form of a horizontal strip. A seal can be installed to provide sound insulation. Return to contents</a>

Requirements for the door frame

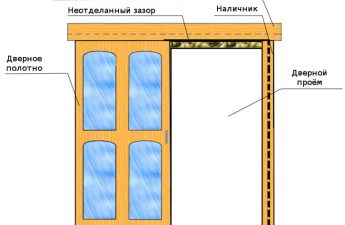

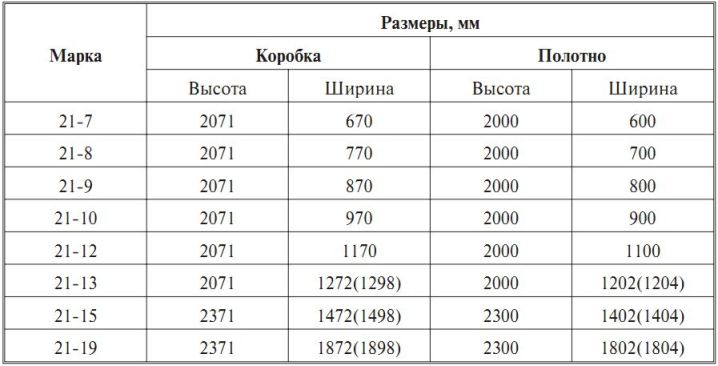

Table of door frame sizes.In order for the door frame to perform its functions, several conditions must be taken into account when choosing or making it. First of all, the door frame must match the dimensions of the doorway - be 20-30 mm smaller than the dimensions of the opening in all directions. The side posts of the frame must be strictly vertical, and the upper crossbar - strictly horizontal. The thickness (width in the transverse direction) of the frame must be selected so that the casing lies on its side edge and the wall without skewing. The thickness can be adjusted by adding. An interior door (its frame) is usually 207 cm high with a width of 80 cm. In bathrooms and toilets, the width of the opening is most often 70 cm. The door frame must have sufficient mechanical strength to hold the door leaf without the slightest deformation. In interior door frames installed in bathrooms and toilets, it is desirable to install thresholds (height above the floor is about 2 cm), which play the role of some sealing of the room. In the kitchen, on the contrary, a threshold is undesirable, and the door leaf has a gap of up to 20 mm at the bottom for ventilation. Return to contents</a>

Table of door frame sizes.In order for the door frame to perform its functions, several conditions must be taken into account when choosing or making it. First of all, the door frame must match the dimensions of the doorway - be 20-30 mm smaller than the dimensions of the opening in all directions. The side posts of the frame must be strictly vertical, and the upper crossbar - strictly horizontal. The thickness (width in the transverse direction) of the frame must be selected so that the casing lies on its side edge and the wall without skewing. The thickness can be adjusted by adding. An interior door (its frame) is usually 207 cm high with a width of 80 cm. In bathrooms and toilets, the width of the opening is most often 70 cm. The door frame must have sufficient mechanical strength to hold the door leaf without the slightest deformation. In interior door frames installed in bathrooms and toilets, it is desirable to install thresholds (height above the floor is about 2 cm), which play the role of some sealing of the room. In the kitchen, on the contrary, a threshold is undesirable, and the door leaf has a gap of up to 20 mm at the bottom for ventilation. Return to contents</a>

Manufacturing of a box of doors

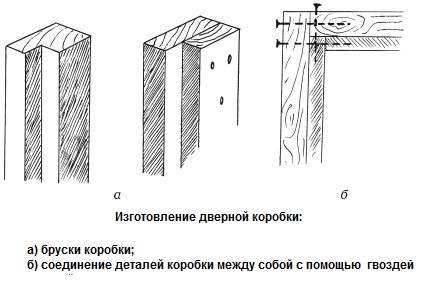

Scheme for manufacturing a door frame.You can assemble a frame for interior doors yourself from a standard wooden frame profile (beam). First, carefully measure the height and width of the doorway. Subtract 30 mm from the height of the opening; measure and cut two beams of this length for the side posts. The upper crossbar is prepared in the same way. Using a special tool - a miter box - the upper ends of the side posts and both ends of the crossbar are cut at an angle of 45º. A special tool is used to accurately form the angle. When preparing the crossbar, take into account that the length of its shorter side after cutting the corners should be the width of the door leaf plus 7 mm. The side post and crossbar are joined at the cut so that the beams are strictly perpendicular. A soft sealing gasket of small thickness (approximately 3 mm) is placed between them in advance. The beams are compressed and secured with clamps. In the long element, two holes are drilled perpendicular to the plane of the cut with a diameter of 4 mm. The joint is pulled together with screws through the holes. It is advisable to coat the plane of the joint with wood glue. The second corner of the frame is pulled together in the same way. For temporary strengthening of the structure, it is recommended to install a removable jumper at the bottom. Even greater confidence in the strength of the joint can be achieved by installing a dowel. To do this, a hole with a diameter of 12-15 mm is drilled in the middle of the joint perpendicular to the plane of the cut (joint of the beams) and a wooden dowel is driven into it. The hole and the connecting element are pre-coated with wood glue. Return to the table of contents</a>

Scheme for manufacturing a door frame.You can assemble a frame for interior doors yourself from a standard wooden frame profile (beam). First, carefully measure the height and width of the doorway. Subtract 30 mm from the height of the opening; measure and cut two beams of this length for the side posts. The upper crossbar is prepared in the same way. Using a special tool - a miter box - the upper ends of the side posts and both ends of the crossbar are cut at an angle of 45º. A special tool is used to accurately form the angle. When preparing the crossbar, take into account that the length of its shorter side after cutting the corners should be the width of the door leaf plus 7 mm. The side post and crossbar are joined at the cut so that the beams are strictly perpendicular. A soft sealing gasket of small thickness (approximately 3 mm) is placed between them in advance. The beams are compressed and secured with clamps. In the long element, two holes are drilled perpendicular to the plane of the cut with a diameter of 4 mm. The joint is pulled together with screws through the holes. It is advisable to coat the plane of the joint with wood glue. The second corner of the frame is pulled together in the same way. For temporary strengthening of the structure, it is recommended to install a removable jumper at the bottom. Even greater confidence in the strength of the joint can be achieved by installing a dowel. To do this, a hole with a diameter of 12-15 mm is drilled in the middle of the joint perpendicular to the plane of the cut (joint of the beams) and a wooden dowel is driven into it. The hole and the connecting element are pre-coated with wood glue. Return to the table of contents</a>

Box installation by own hands

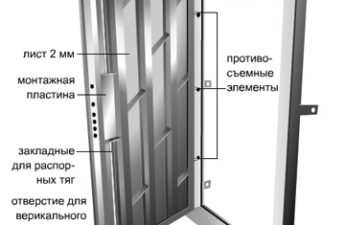

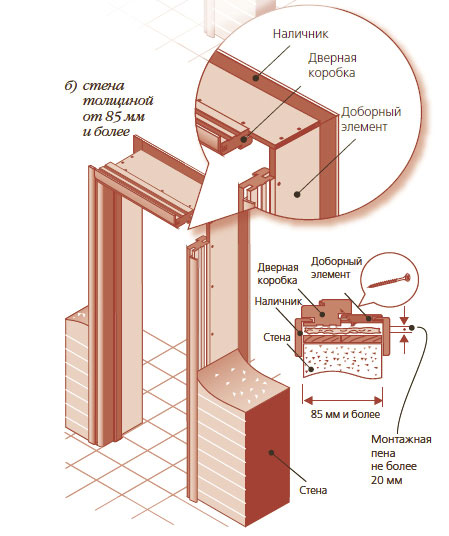

Fixing the door frame in the opening.If the frame is assembled securely, it can be installed in the doorway. Installation begins with the installation of the threshold. A wooden strip about 20 mm thick and the width equal to the width of the doorway pier is fixed to the floor using dowels. The strip is preliminarily rounded along the upper edges. The dowels are driven into the floor. The threshold is fastened with screws into the dowels. The length of the threshold is equal to the width of the doorway. The easiest way to install a door frame in an opening is to fasten it using dowels. To do this, 3 holes are drilled in the side posts - at a distance of 10-15 cm from the edges and in the center. 2 holes are drilled in the crossbar at equal distances. The frame is placed in the doorway and the pier of the opening is marked through the holes in the beams. In the marked places, holes with a diameter of 8 mm are made with a hammer drill and dowels are driven in. The frame is secured with screws in the dowels. The verticality of the posts and the horizontality of the crossbar are checked. If necessary, adjustments are made using spacers, wedges and screwing in screws with different forces. The screw heads are sunk into the wood after the frame is finally positioned. If the thickness of the frame is not enough, then extensions are installed, they are fastened in the same way as the fastening of the beams of the door frame. The thickness of the extension must strictly correspond to the thickness of the frame beam. The extension must not rise above the surface of the frame beam. A rubber sealing tape (if necessary) is placed in the groove of the profile along the entire perimeter of the frame. If the groove is not provided in the profile, then the seal is glued to the beam in the form of a thin rubber strip. Return to the table of contents</a>

Fixing the door frame in the opening.If the frame is assembled securely, it can be installed in the doorway. Installation begins with the installation of the threshold. A wooden strip about 20 mm thick and the width equal to the width of the doorway pier is fixed to the floor using dowels. The strip is preliminarily rounded along the upper edges. The dowels are driven into the floor. The threshold is fastened with screws into the dowels. The length of the threshold is equal to the width of the doorway. The easiest way to install a door frame in an opening is to fasten it using dowels. To do this, 3 holes are drilled in the side posts - at a distance of 10-15 cm from the edges and in the center. 2 holes are drilled in the crossbar at equal distances. The frame is placed in the doorway and the pier of the opening is marked through the holes in the beams. In the marked places, holes with a diameter of 8 mm are made with a hammer drill and dowels are driven in. The frame is secured with screws in the dowels. The verticality of the posts and the horizontality of the crossbar are checked. If necessary, adjustments are made using spacers, wedges and screwing in screws with different forces. The screw heads are sunk into the wood after the frame is finally positioned. If the thickness of the frame is not enough, then extensions are installed, they are fastened in the same way as the fastening of the beams of the door frame. The thickness of the extension must strictly correspond to the thickness of the frame beam. The extension must not rise above the surface of the frame beam. A rubber sealing tape (if necessary) is placed in the groove of the profile along the entire perimeter of the frame. If the groove is not provided in the profile, then the seal is glued to the beam in the form of a thin rubber strip. Return to the table of contents</a>

Finishing work

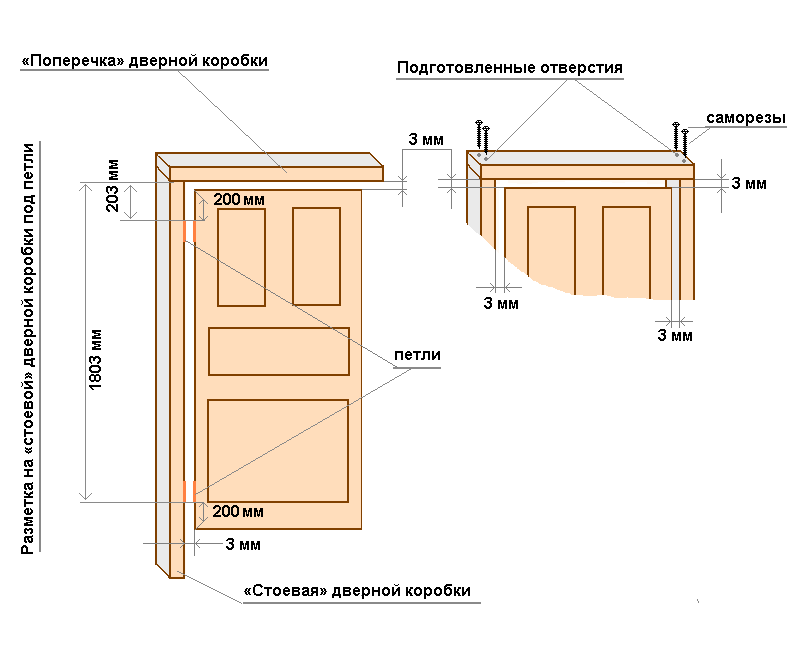

Marking the door frame for hinges.The question of how to assemble the frame of the interior door has already been resolved, but its finishing remains. To begin with, the gap between the doorway pier and the frame is sealed with mounting foam. After hardening, excess foam is carefully cut off and the gap area is cleaned and sanded. The door frames are installed on both sides of the door frame. For this, 3 strips are cut off - two for overlapping the side posts of the frame and one for overlapping the crossbar (on each side of the frame). The top of the side frames and both ends of the horizontal frame are cut at an angle of 45º. The frames are installed in their places so that their side cut exactly coincides with the edge of the door frame, and the second cut is on the surface of the wall. The frames are secured with screws. The screw heads are sunk into the wood. All gaps - between the casing and the frame, between the extension and the beam, at the joints of the beams of the frame and the casing - are filled with wood putty. The putty is applied in two layers. First, the gap is filled, and after it hardens, the finishing putty is applied. After drying, the putty is carefully rubbed and sanded with sandpaper. After this, the place for installing the door leaf hinges is marked. A recess for the hinge is made with a chisel. The hinges are secured with screws. Return to the table of contents</a>

Marking the door frame for hinges.The question of how to assemble the frame of the interior door has already been resolved, but its finishing remains. To begin with, the gap between the doorway pier and the frame is sealed with mounting foam. After hardening, excess foam is carefully cut off and the gap area is cleaned and sanded. The door frames are installed on both sides of the door frame. For this, 3 strips are cut off - two for overlapping the side posts of the frame and one for overlapping the crossbar (on each side of the frame). The top of the side frames and both ends of the horizontal frame are cut at an angle of 45º. The frames are installed in their places so that their side cut exactly coincides with the edge of the door frame, and the second cut is on the surface of the wall. The frames are secured with screws. The screw heads are sunk into the wood. All gaps - between the casing and the frame, between the extension and the beam, at the joints of the beams of the frame and the casing - are filled with wood putty. The putty is applied in two layers. First, the gap is filled, and after it hardens, the finishing putty is applied. After drying, the putty is carefully rubbed and sanded with sandpaper. After this, the place for installing the door leaf hinges is marked. A recess for the hinge is made with a chisel. The hinges are secured with screws. Return to the table of contents</a>

Required Tools

To solve the problem of assembling the interior door frame, you need to prepare the following tool: Tools for installing door frames.

Tools for installing door frames.

- Bulgarian;

- perforator;

- electric drill;

- Screwdriver;

- hacksaw;

- chisel;

- pliers;

- screwdriver;

- level;

- plumb bob;

- file;

- a grinding skins;

- roulette;

- plane;

- putty knife;

- paint brush;

- a hammer.

The door frame determines the appearance of the entire interior door. You can make and install the door frame yourself. To do this, you need to put in a little effort and follow the recommendations.