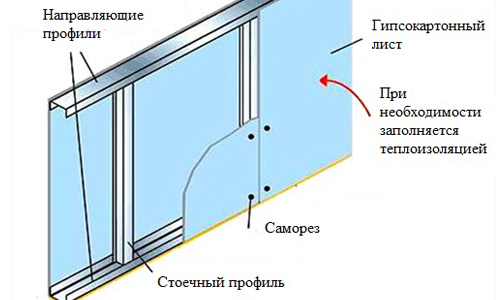

Drywall is increasingly used for interiorfinishing of premises. This building material is great for leveling walls and ceilings, creating arches and partitions. Using gypsum board, you, if not saving money, then significantly win in the speed of repair and the quality of surface leveling. Drywall is a material on which you can carry out finishing with almost any cladding. Scheme of the device of a wall from plasterboard.

Scheme of the device of a wall from plasterboard.

Disadvantages of drywall

GKL also has disadvantages that prevent it from becoming the undisputed leader in the construction materials market. The disadvantages of gypsum board are as follows:

- a ceiling and it is possible to equip in dry enough premises (abilities of moisture-resistant panels on resistance to moisture are rather doubtful);

- After installing the GKL on the ceiling and walls, the room becomes lower and narrower, which is not so noticeable in spacious and high rooms, but is critical for small rooms with low floors;

- Drywall is far from being a durable building material (although the downside of this indicator is its ease of processing).

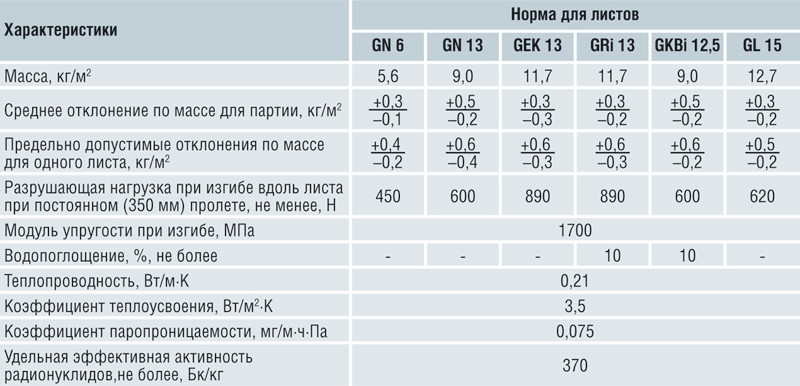

Physical and technical characteristicsplasterboard sheets. However, you can put insulation in the space of the lathing on which the sheets are attached, and various communications can be hidden under the plasterboard cladding. Having weighed all the pros and cons, you can choose the building material that best suits your requirements, but if you decide, then to get a high-quality result you need to follow the recommendations that will be given below. Return to contents</a>

Physical and technical characteristicsplasterboard sheets. However, you can put insulation in the space of the lathing on which the sheets are attached, and various communications can be hidden under the plasterboard cladding. Having weighed all the pros and cons, you can choose the building material that best suits your requirements, but if you decide, then to get a high-quality result you need to follow the recommendations that will be given below. Return to contents</a>

Frameless technology of fastening GKL

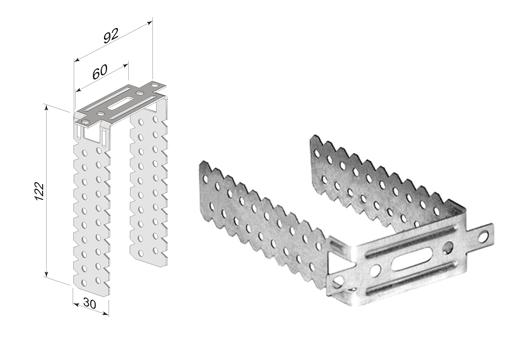

A method without using metal orwooden lathing is just right for repairing small rooms. The loss of space will be minimal. However, panels can be installed on walls that do not require or almost do not require preliminary alignment. The surfaces themselves are prepared for pasting with plasterboard panels as follows. Figure 1. Diagram of the U-shaped suspension device.

Figure 1. Diagram of the U-shaped suspension device.

It is possible to improve the adhesion quality of plasterboardwith the wall, attaching a plastic reinforcing mesh to the latter. It is attached to the wall with dowel-nails every 25-30 cm. After this, a thick adhesive mixture is applied to the primed surface with a brush or roller, and the mesh is pressed into it with a spatula. Return to contents</a>

Installation of plasterboard on the frame

Figure 2. Scheme of fastening gypsum board to the lathing.The frame technology of gypsum board installation is more widespread. Wooden bars are sometimes used as lathing, but the main material for the frame is metal profiles. With their help (of course, taking into account the losses in the space of the room) you can align any walls. To attach the profiles to the surface and adjust their position, there are U-shaped hangers (Fig. 1). Guide profiles are attached to the ceiling and floor. Their position relative to each other is checked with a plumb line. The profiles must be in the same vertical plane. CW profiles are installed in the guide profiles. They must be mounted strictly vertically. The distance between the centers of adjacent CW should be 60 cm. The U-shaped hangers are also attached to the wall with this step. The last vertical profile is attached 20 cm from the corner. The bottom row of U-shaped hangers is 30 cm from the floor. The vertical step between them is 60 cm. To strengthen the frame, you can use horizontal crossbars. Of course, the profile is installed along the perimeter of window and door openings. The frame elements are connected with 3 x 9.5 screws. Fig. 2 shows how the plasterboards are attached to the lathing. Note that the height of the walls here is greater than the length of the plasterboard sheet. In this case, the horizontal joints of the sheets in adjacent rows should not be at the same level, as this will weaken the wall.

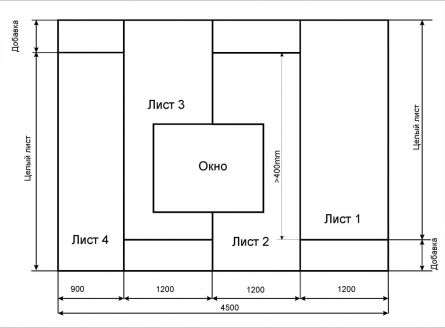

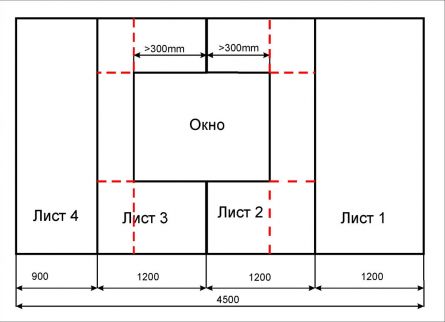

Figure 2. Scheme of fastening gypsum board to the lathing.The frame technology of gypsum board installation is more widespread. Wooden bars are sometimes used as lathing, but the main material for the frame is metal profiles. With their help (of course, taking into account the losses in the space of the room) you can align any walls. To attach the profiles to the surface and adjust their position, there are U-shaped hangers (Fig. 1). Guide profiles are attached to the ceiling and floor. Their position relative to each other is checked with a plumb line. The profiles must be in the same vertical plane. CW profiles are installed in the guide profiles. They must be mounted strictly vertically. The distance between the centers of adjacent CW should be 60 cm. The U-shaped hangers are also attached to the wall with this step. The last vertical profile is attached 20 cm from the corner. The bottom row of U-shaped hangers is 30 cm from the floor. The vertical step between them is 60 cm. To strengthen the frame, you can use horizontal crossbars. Of course, the profile is installed along the perimeter of window and door openings. The frame elements are connected with 3 x 9.5 screws. Fig. 2 shows how the plasterboards are attached to the lathing. Note that the height of the walls here is greater than the length of the plasterboard sheet. In this case, the horizontal joints of the sheets in adjacent rows should not be at the same level, as this will weaken the wall. Figure 3.Installation diagram of joints of plasterboard sheets. In addition, the joints of the plasterboard should not coincide with the perimeter lines of window and door openings. They should be at least 30 cm from the latter (in Fig. 3, the red dotted line marks the lines along which plasterboard joints cannot be arranged). It should be added that when changing the dimensions of the plasterboard inserts, it is necessary to make adjustments to the installation of the profiles. Plasterboard is easy to process, so it can be cut with a construction knife or a hacksaw. After cutting, the edge of the sheet is processed with a block covered with sandpaper. It must be sanded so that when joining the sheets, the seam looks like a groove expanding towards the outside (it will be easier to putty it later). As already written, plasterboard is a fragile material. Its installation must be approached responsibly:

Figure 3.Installation diagram of joints of plasterboard sheets. In addition, the joints of the plasterboard should not coincide with the perimeter lines of window and door openings. They should be at least 30 cm from the latter (in Fig. 3, the red dotted line marks the lines along which plasterboard joints cannot be arranged). It should be added that when changing the dimensions of the plasterboard inserts, it is necessary to make adjustments to the installation of the profiles. Plasterboard is easy to process, so it can be cut with a construction knife or a hacksaw. After cutting, the edge of the sheet is processed with a block covered with sandpaper. It must be sanded so that when joining the sheets, the seam looks like a groove expanding towards the outside (it will be easier to putty it later). As already written, plasterboard is a fragile material. Its installation must be approached responsibly:

- it is attached to the carcass by screws 3 x 25;

- screw fasteners must be strictly perpendicular to the sheet of building material;

- the heads of self-tapping screws should be somewhat recessed into it, at the same time, try not to break the outer cardboard layer;

- if the screw "fell through", retreat 5 cm and twist the other;

- screws are screwed into the GCR with a step of not more than 25 cm in the central part of the panel and not more than 15 cm along the edges of the sheet;

- near the corners of the screw it is better not to twist, the minimum distance from the corner to the nearest samorez should be 5 cm;

- The distance from the place of screwing the fastener to the edge of the plasterboard should not be less than 1 cm.

Return to Contents</a>

Baffle installation

Sometimes you have to redesign a room.In this case, it is easier to install a plasterboard wall than others. A line of the partition is marked on the floor with a painter's cord. Using a plumb line or level, mark the verticals on the walls. Then mark the ceiling line. Guide profiles are attached to the surfaces along these marks. Before installation, the planes that will be adjacent to the ceiling, walls and floor are pasted over with soundproofing tape. When installing the guides, observe the fastening step of 30 cm. The perimeter of the light wall is ready. Now you can start installing the vertical profiles. First, the doorway posts are installed (if provided). The length of the posts should be 0.5 cm less than the distance between the floors. The profiles are mounted according to the level. To strengthen the structure of the opening, wooden blocks of the same length as the metal posts are inserted into the profiles. The wood is pulled together with the profiles with self-tapping screws. Then the remaining elements of the frame are installed. It can be made stronger by fixing lintels between the verticals. GKL are fixed on one side of the lathing. Upon completion of the operation, cables are inserted into the lathing and thermal insulation is laid. The construction of the partition is completed by installing gypsum board on the other side of the frame. After installation, the seams between the gypsum boards are filled with putty and sealed with serpyanka. Putty is also applied to the places where the fasteners are cut in. The gypsum board coverings are treated with a primer, and then the entire surface of the walls is finally puttied. After drying, the finishing layer is sanded, and the gypsum board is covered with finishing materials.