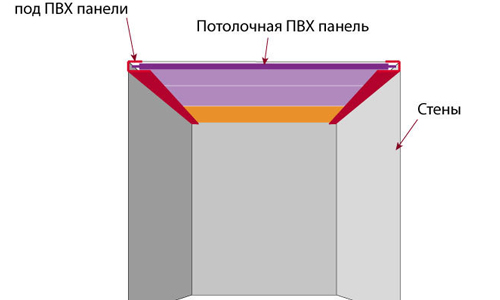

The construction materials market is saturated with finishing materialssystems that have significantly expanded the range of design possibilities in construction. In particular, it has become easier to make such an important part of the interior as the ceiling a real work of architectural art. Scheme of ceiling covering with plastic.In pursuit of high quality and comfort, many ask the question: how with plastic? If fragile and capricious plastic is irreparably damaged during installation, it is possible that the entire surface of the ceiling will have to be sheathed. Therefore, you need to figure out how to properly sheathe the ceiling.

Scheme of ceiling covering with plastic.In pursuit of high quality and comfort, many ask the question: how with plastic? If fragile and capricious plastic is irreparably damaged during installation, it is possible that the entire surface of the ceiling will have to be sheathed. Therefore, you need to figure out how to properly sheathe the ceiling.

Features of the arrangement of the false ceiling with plastic panels

The creation of a ceiling from this material has a number ofFeatures. Made of polyvinyl chloride (PVC), the coating is environmentally friendly, which is very important for residential premises. Many customers choosing between plasterboard and plastic are attracted to the latter by its almost absolute moisture resistance. This is primarily important for rooms with high humidity (shower, bathroom). In addition, this material is very good when the master sets a goal to get an almost perfectly flat ceiling surface. Types of plastic ceiling panels.Meanwhile, in this case, it is necessary to take into account some of the texture nuances of the material. In particular, before covering the ceiling with plastic, you should think about the difference in visual perception between glossy and matte panels. The glossy version with its reflective surface looks very original, it seems to expand the volume of the room, and also (this is highly appreciated by professionals) makes the joints between the components almost invisible. At the same time, having chosen a matte or floral-patterned product, you must be prepared for the fact that it will not be possible to reliably hide the joint lines. In order to technically correctly cover the ceiling with plastic, you must pay attention to its purpose when buying. After all, this material is not universal, it is produced for installation either on the ceiling or on the walls. Moreover, ceiling plastic is much lighter than wall plastic. It should be borne in mind that installing a heavier wall version on the ceiling will necessarily lead to an increase in the load on the frame of the sheathing. This may be unsafe. Return to the table of contents</a>

Types of plastic ceiling panels.Meanwhile, in this case, it is necessary to take into account some of the texture nuances of the material. In particular, before covering the ceiling with plastic, you should think about the difference in visual perception between glossy and matte panels. The glossy version with its reflective surface looks very original, it seems to expand the volume of the room, and also (this is highly appreciated by professionals) makes the joints between the components almost invisible. At the same time, having chosen a matte or floral-patterned product, you must be prepared for the fact that it will not be possible to reliably hide the joint lines. In order to technically correctly cover the ceiling with plastic, you must pay attention to its purpose when buying. After all, this material is not universal, it is produced for installation either on the ceiling or on the walls. Moreover, ceiling plastic is much lighter than wall plastic. It should be borne in mind that installing a heavier wall version on the ceiling will necessarily lead to an increase in the load on the frame of the sheathing. This may be unsafe. Return to the table of contents</a>

Materials and tools needed for plating

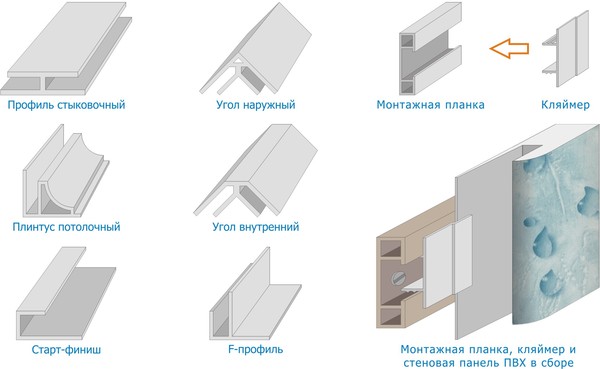

In order to qualitatively cover the ceiling with PVC panels, it is necessary to responsibly approach the selection of materials and tools for the specified work. The list of everything necessary looks like this: Materials for working with plastic panels.

Materials for working with plastic panels.

- plastic panels in the required quantity;

- Starting profile for the frame (fixed on the upper perimeter of the room and closes the ends of the plastic plate);

- connecting H-profile;

- skeleton F-profile;

- outer and inner corners made of plastic;

- Screwdriver;

- perforator;

- hacksaw for metal (grinder - for metal profiles);

- a hammer;

- pliers;

- construction knife;

- corner;

- level (water or laser);

- measuring tape;

- upholstery paint.

To calculate the finishing material, you needdetermine the total area of the ceiling, adding 10-15% of the area to the resulting volume, which will be required in case of unsuccessful trimming and defects. It is recommended to provide approximately the same amount of additional reserve for decorative finishing skirting boards. Return to contents</a>

How to fix the ceiling: step by step execution of works

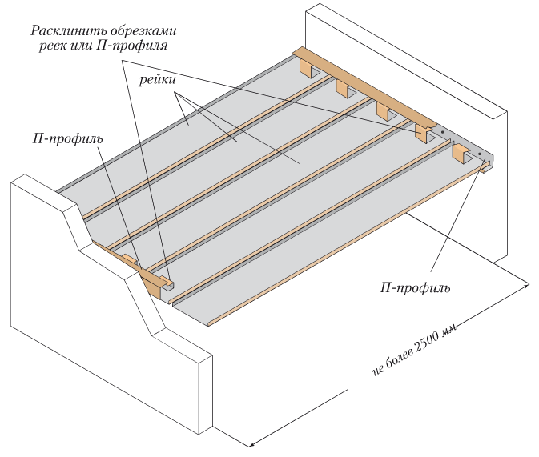

Since the main ceiling will be laterhidden under the false ceiling, its surface as a whole does not require additional preparation. Therefore, at the initial stage of work, you should focus on accurately setting the level of the future ceiling covering made of PVC strips. Scheme of fixing a closed plastic ceiling.Here all the details should be taken into account. First of all - the hidden wiring diagram and the distance between the main ceiling and the plastic, which is important when installing built-in lamps. When marking the ceiling level, you cannot initially allow the surface of the ceiling to be skewed. Otherwise, if there is a crooked arch, all efforts will be in vain. Therefore, you should measure the height in all corners of the room and find the lowest of them. If built-in lamps are not supposed, in this corner they retreat about 4-6 cm from the ceiling and mark the level of the future plastic surface. Then, using a building level, several mark points are marked along the entire perimeter of the room. Using a painter's cord, a solid line is beaten off on the walls, which should pass exactly along the marked beacons. Along the drawn strip, at approximately equal distances from each other, holes are drilled for mounting dowels using a hammer drill. The corresponding holes are also made in the profile, which is pre-cut to the length of the perimeter of the room. Dowels are then inserted into these holes, and the profiles are securely attached to the wall and to each other with special bugs. The next step is to install hangers on the ceiling that will hold the profiles. Using a hammer drill and dowels, they are attached to the ceiling along lines drawn parallel to the length of the room. Depending on the dimensions of the room, the number of hanging rows may vary, but there should be a distance of approximately 60 cm between the rows. Before fixing the frame profiles, a fishing line (cord) is tightly pulled between the starting profiles along the lines of installing the hangers. This fishing line will mark the horizon on which the frame profiles should be fixed. It is better to do this with an assistant. After completing the installation of the profiles, the ends of the hangers are bent upwards. After this, you can begin to sheathe the ceiling with plastic panels. The first strip must be very carefully and accurately (without distortions) fixed with self-tapping screws in all places of contact with the profiles. The remaining panels are added to the previously fixed elements using the constructor method, inserting into each other using special mounting grooves, and then fastened to the profiles at their points of contact. During the installation of the plastic ceiling, it is necessary to lightly tap the edges of the element being installed with your hand all the time so that the panels fit as tightly as possible to each other. This is done to avoid the formation of noticeable gaps at the seams. Return to the table of contents</a>

Scheme of fixing a closed plastic ceiling.Here all the details should be taken into account. First of all - the hidden wiring diagram and the distance between the main ceiling and the plastic, which is important when installing built-in lamps. When marking the ceiling level, you cannot initially allow the surface of the ceiling to be skewed. Otherwise, if there is a crooked arch, all efforts will be in vain. Therefore, you should measure the height in all corners of the room and find the lowest of them. If built-in lamps are not supposed, in this corner they retreat about 4-6 cm from the ceiling and mark the level of the future plastic surface. Then, using a building level, several mark points are marked along the entire perimeter of the room. Using a painter's cord, a solid line is beaten off on the walls, which should pass exactly along the marked beacons. Along the drawn strip, at approximately equal distances from each other, holes are drilled for mounting dowels using a hammer drill. The corresponding holes are also made in the profile, which is pre-cut to the length of the perimeter of the room. Dowels are then inserted into these holes, and the profiles are securely attached to the wall and to each other with special bugs. The next step is to install hangers on the ceiling that will hold the profiles. Using a hammer drill and dowels, they are attached to the ceiling along lines drawn parallel to the length of the room. Depending on the dimensions of the room, the number of hanging rows may vary, but there should be a distance of approximately 60 cm between the rows. Before fixing the frame profiles, a fishing line (cord) is tightly pulled between the starting profiles along the lines of installing the hangers. This fishing line will mark the horizon on which the frame profiles should be fixed. It is better to do this with an assistant. After completing the installation of the profiles, the ends of the hangers are bent upwards. After this, you can begin to sheathe the ceiling with plastic panels. The first strip must be very carefully and accurately (without distortions) fixed with self-tapping screws in all places of contact with the profiles. The remaining panels are added to the previously fixed elements using the constructor method, inserting into each other using special mounting grooves, and then fastened to the profiles at their points of contact. During the installation of the plastic ceiling, it is necessary to lightly tap the edges of the element being installed with your hand all the time so that the panels fit as tightly as possible to each other. This is done to avoid the formation of noticeable gaps at the seams. Return to the table of contents</a>

Completion of work

Before covering the ceiling with plastic, on the panels,where the built-in light will be installed, a hole of the appropriate size is cut out. You can attach the plastic to the profiles only after the electrical wiring has been installed under the covering. In this case, the wire must be laid in a special corrugated plastic sleeve. It is not recommended to use a hammer for tight shrinkage of the panels. Otherwise, you can damage the edges of the fairly soft plastic fragments and get cracks at the joints. It is always necessary to remember that the marking of the plastic and cutting of the strips along the marks are carried out exclusively on their front side. Experienced craftsmen advise constantly checking the sheathing for distortions and gaps during the work. If this is not done, strong irregularities may appear by the end of the work, due to which you will have to redo the entire work. If you follow all the simple technical rules and recommendations of specialists, then you can sheathe the ceiling quickly and very efficiently.