You can lay parquet boards yourself.When choosing this material, experts recommend paying attention to the top layer. The service life of the finishing coating depends on it. If the thickness of the top layer is 7 mm, then it is made of veneer. For flooring in residential and public spaces, parquet boards with a thickness of 13-15 mm are used. If this figure exceeds 20 mm, then the working layer is 4-6 mm. Such material is used for finishing flooring in rooms with high load resistance. Structure of parquet board.

Structure of parquet board.

Basic Methods

You can lay parquet boards in the following ways:

- floating;

- glutinous;

- with the help of nails;

- on the lag.

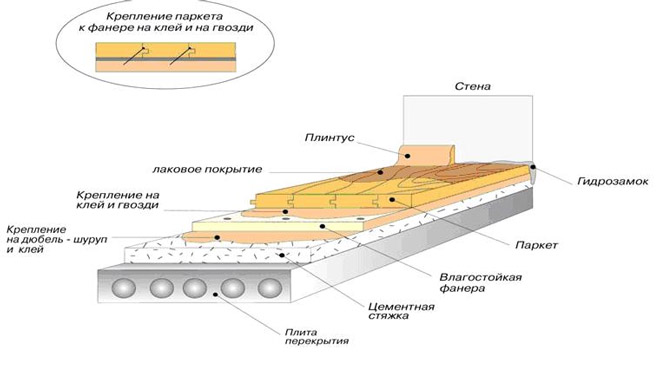

Laying parquet boards with your own hands.For small rooms, use the floating method. The base is prepared in advance. The parquet board must have a good lock. Installation of such a system with glue is a labor-intensive process. If a solid parquet board is laid on the floor, then nails are used to fix it to the subfloor. To arrange such a floor with logs, you will need to keep a step of 30-40 cm between them. For independent use, it is recommended to use the floating method. Initially, the base is prepared for the upcoming work. For this, you can use a concrete screed or adjustable wooden floors. In rooms with low ceilings, use the 1st option, since any height is typical for the screed. The adjustable system reduces the height of the room by 3 cm and, if necessary, raises the floor level by 5 cm or more. This design allows you to lay communications under the floor, saving time on preparing the subfloor. The concrete screed must be poured without height differences. Otherwise, the parquet floor will creak. First, set up beacons (using a building level). If the overall thickness of the screed is insignificant, then use a self-leveling mixture. It will take 3-4 weeks for the screed to dry. The base of the adjustable floor is presented in the form of a moisture-resistant plywood plate. Threaded legs are screwed into it. The last elements allow you to get the ideal horizontal, necessary for the arrangement of the coating in question. The service life of such a structure exceeds 50 years. Return to the table of contents</a>

Laying parquet boards with your own hands.For small rooms, use the floating method. The base is prepared in advance. The parquet board must have a good lock. Installation of such a system with glue is a labor-intensive process. If a solid parquet board is laid on the floor, then nails are used to fix it to the subfloor. To arrange such a floor with logs, you will need to keep a step of 30-40 cm between them. For independent use, it is recommended to use the floating method. Initially, the base is prepared for the upcoming work. For this, you can use a concrete screed or adjustable wooden floors. In rooms with low ceilings, use the 1st option, since any height is typical for the screed. The adjustable system reduces the height of the room by 3 cm and, if necessary, raises the floor level by 5 cm or more. This design allows you to lay communications under the floor, saving time on preparing the subfloor. The concrete screed must be poured without height differences. Otherwise, the parquet floor will creak. First, set up beacons (using a building level). If the overall thickness of the screed is insignificant, then use a self-leveling mixture. It will take 3-4 weeks for the screed to dry. The base of the adjustable floor is presented in the form of a moisture-resistant plywood plate. Threaded legs are screwed into it. The last elements allow you to get the ideal horizontal, necessary for the arrangement of the coating in question. The service life of such a structure exceeds 50 years. Return to the table of contents</a>

Basic work

The parquet board is kept indoors, inwhich its installation involves, for 2 days. A synthetic, cork or natural backing is placed under the material. This technology will protect the boards from excess moisture. The seams between the sheets of the base material are sealed with tape. The parquet board is laid using a floating method, parallel or diagonally. Types of parquet board installation.The last option increases the board consumption by 2-7%. Installation work is carried out using a level, tape measure, grinder, saw. First, the first 2 rows of the main material are installed. They are placed parallel to the sun rays falling into the room. The first 4 planks are installed in a checkerboard pattern. For this, wedges are installed. When carrying out such work, a distance of 10 mm is maintained between the wall and the board. 2 panels are pressed against the spacer wedges. Then another row is installed. The material from the 2nd row, which is laid near the wall, should be 80 cm long. Experts allow a 50 cm gap between the seams of rows laid parallel to each other. Then the 2nd board of the other row is laid. It is driven into the end lock with the 1st plank. For tight fixation in the lock of the 2nd row, the parquet boards are driven in with a bar. The same is done when laying the remaining planks. Before installing the last row, measure the distance from the wall to the previous row. The locking edge provided on the groove of the previous row is sawed off. The groove is filled with glue, and the parquet board is laid. For this, use a mounting paw or clamp. Upon completion of the work, install the skirting board. Remove the wedges beforehand. The skirting board should be attached to the wall (not close to the floor). It should cover the expansion gap. A similar method is used to lay the board diagonally, with the panels being positioned at an angle of 45° relative to the room axis. Return to contents</a>

Types of parquet board installation.The last option increases the board consumption by 2-7%. Installation work is carried out using a level, tape measure, grinder, saw. First, the first 2 rows of the main material are installed. They are placed parallel to the sun rays falling into the room. The first 4 planks are installed in a checkerboard pattern. For this, wedges are installed. When carrying out such work, a distance of 10 mm is maintained between the wall and the board. 2 panels are pressed against the spacer wedges. Then another row is installed. The material from the 2nd row, which is laid near the wall, should be 80 cm long. Experts allow a 50 cm gap between the seams of rows laid parallel to each other. Then the 2nd board of the other row is laid. It is driven into the end lock with the 1st plank. For tight fixation in the lock of the 2nd row, the parquet boards are driven in with a bar. The same is done when laying the remaining planks. Before installing the last row, measure the distance from the wall to the previous row. The locking edge provided on the groove of the previous row is sawed off. The groove is filled with glue, and the parquet board is laid. For this, use a mounting paw or clamp. Upon completion of the work, install the skirting board. Remove the wedges beforehand. The skirting board should be attached to the wall (not close to the floor). It should cover the expansion gap. A similar method is used to lay the board diagonally, with the panels being positioned at an angle of 45° relative to the room axis. Return to contents</a>

Recommendations for laying the board

To ensure that the parquet floor is level, it is recommendedsand it. Then the boards are varnished and dried. If the floor is made of modern material, such sanding is not carried out. This is due to the good geometry of the planks and the varnish coating applied to the parquet board by the manufacturer. To return the coating to its original appearance, sanding is carried out to a depth of 0.5 mm. Then varnish is applied to the surface. If the parquet board has 3 layers, then a belt grinding machine is used for its processing. Sandpaper with a grain size of 40 is used in advance. Then an abrasive is required. If necessary, the parquet board is laid on a heated floor. The heating system is turned on 2-3 weeks before the start of finishing work. A board with a thickness of 13-15 mm can be laid on a heated floor. Such a coating requires waterproofing. It is not recommended to lay the board in a room with high traffic. Otherwise, the service life of the floor will be significantly reduced. If there are many corners in the room, the flooring is installed diagonally. Wax or paraffin impregnation ensures good fixation of the locks, significantly extending the service life of the parquet.</ ul>